6A-35POWER TRIM90-13645--2 495

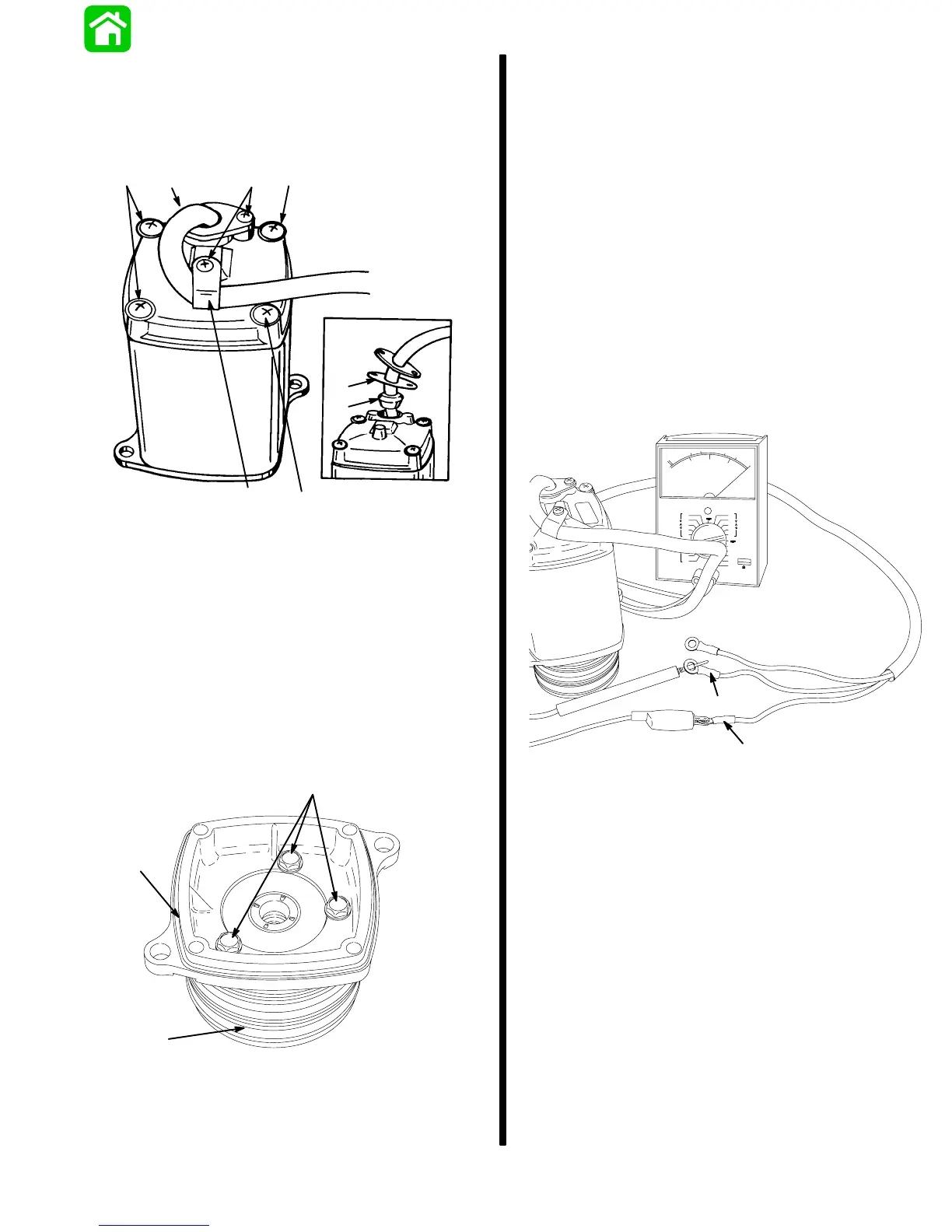

2. Remove screws and clamp.

Remove screws.

Lift motor from end cap, taking care not to drop

armature.

51345

a

b

c

d

e

a

c

c

a - Screw (3)

b - Clamp

c - Screw (4)

d - Gasket

e - Grommet

3. Remove bolts.

NOTE:

Some motors use 2 bolts to secure end frame

cap.

Lift end cap from pump.

Follow “Reassembly” and “Installation” instruc-

tions in “Motor Repair,” following.

18469

a

b

c

a - Bolts

b - End Cap

c - Pump

Motor and Electrical

Tests/Repair

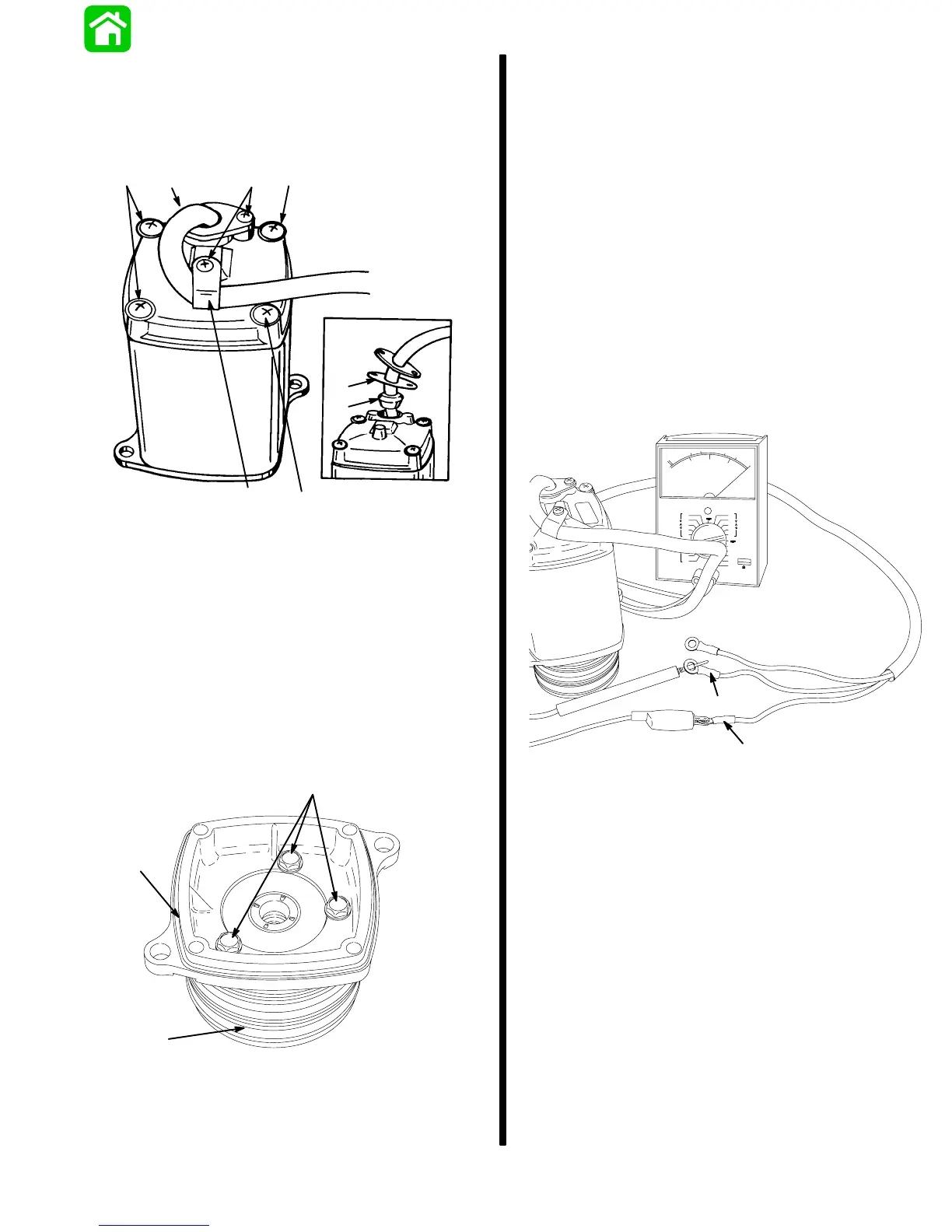

Thermal Overload Switch Test

IMPORTANT: If trim pump has just been operated,

do not run pump for approximately one minute be-

fore testing thermal overload switch. After this

period of time the switch should close (reset it-

self) and pump again may be operated. Perform

the following check(s) only if switch does not re-

set itself.

MOTOR ASSEMBLED

Connect Ohmmeter (R x 1 scale) leads as shown. If

switch is good, full continuity (zero ohms) will be indi-

cated. If full continuity is not indicated, disassemble

motor and recheck switch per instructions, following.

18459

a

b

a - Motor Wire (BLUE)

b - Motor Wire (BLACK)

Loading...

Loading...