6A-38 POWER TRIM 90-13645--2495

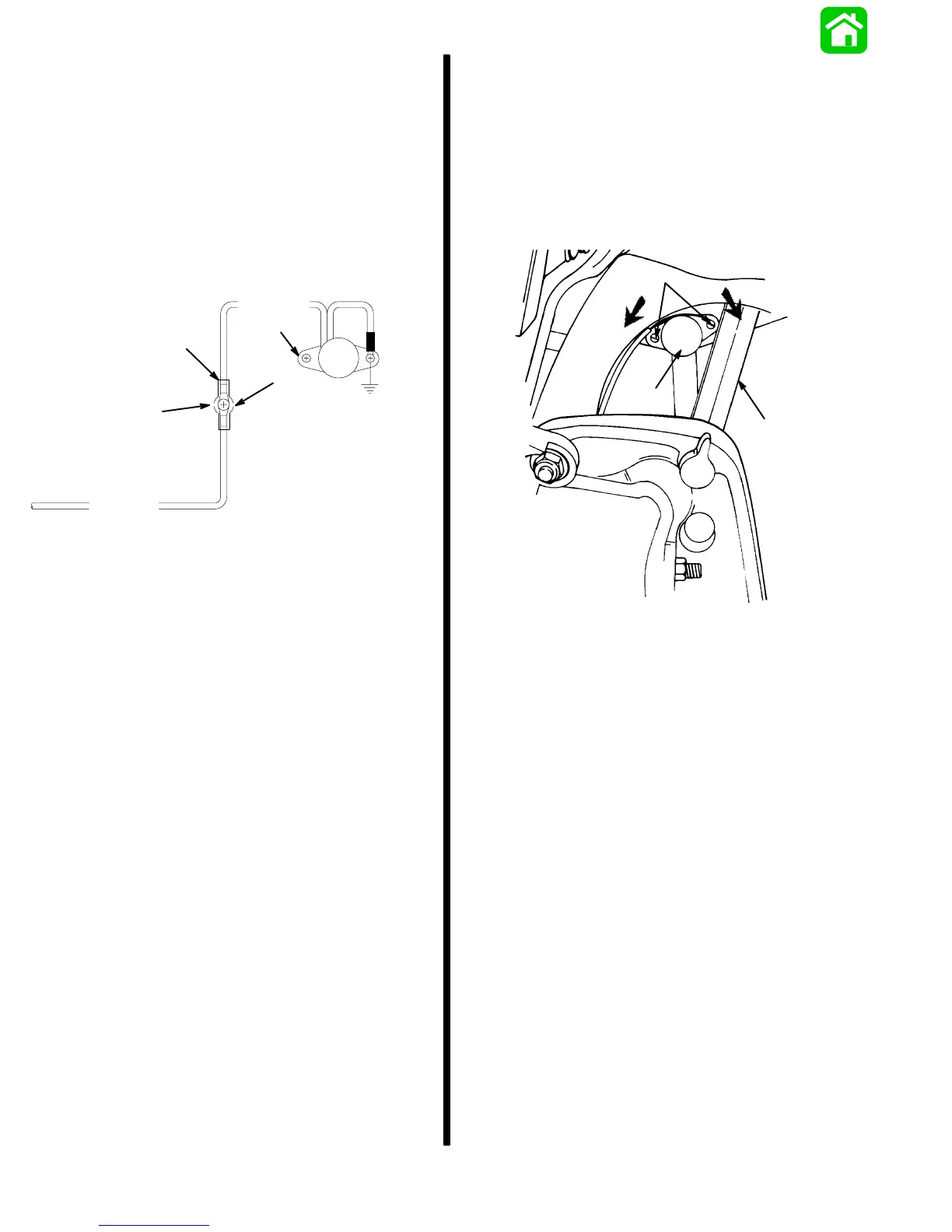

Trim Sender (Optional Accessory) Test

Check trim sender BLACK lead for proper ground.

Trim engine to full “Down” position.

Place ignition switch in “Off” position.

Connect Ohmmeter (R x 1 scale) leads between

engine ground and Point 1.

Depress “Up” trim button. Ohmmeter needle should

move as the engine is trimmed up. If needle does not

move, the trim sender is defective.

a

b

c

BRN/WHT

BLK

BRN/WHT

1

a-Trim Sender

b-Connect with Screw and Hex Nut (Coat with Liquid

Neoprene)

c-Rubber Sleeve (Slide Over Connection)

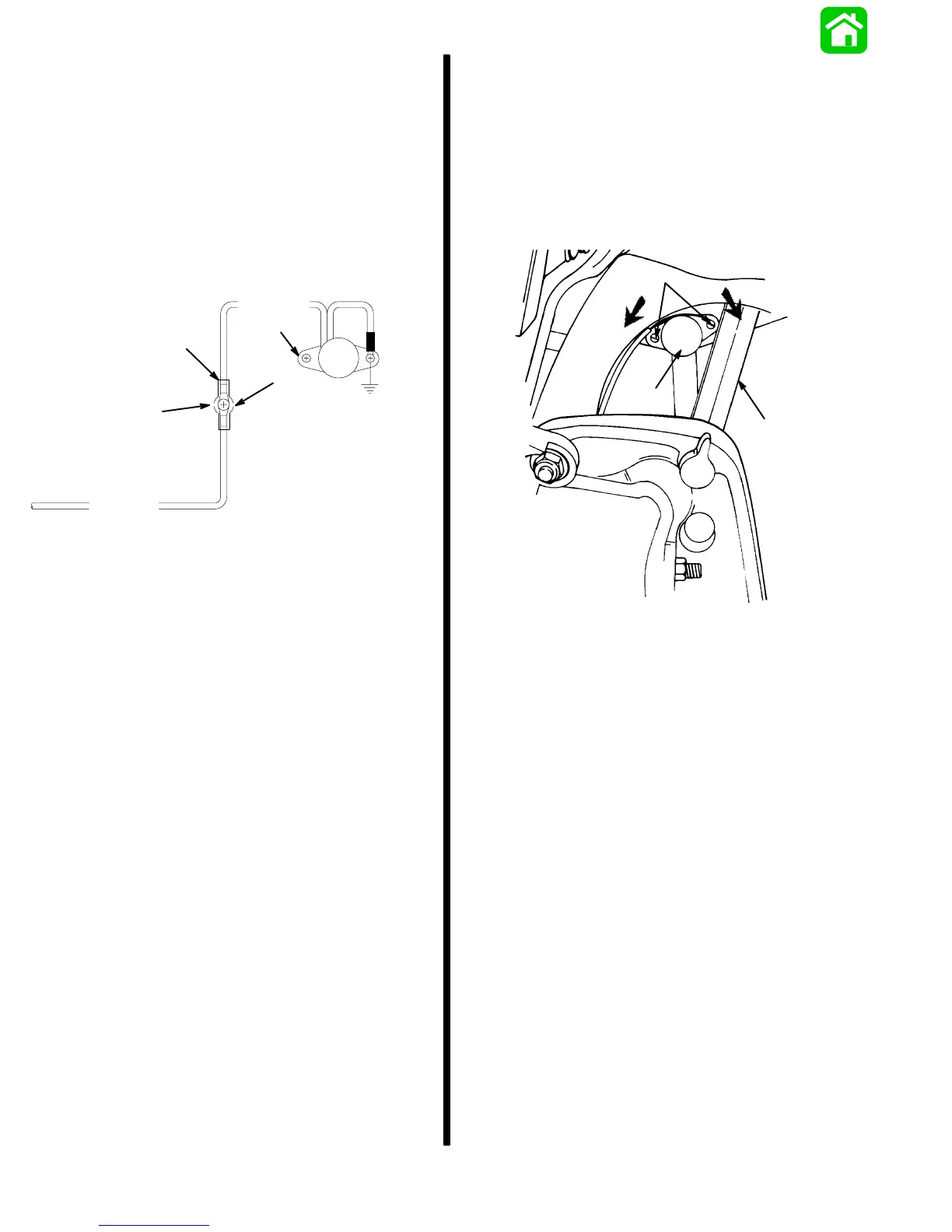

Trim Indicator Gauge (Optional

Accessory) Needle Adjustment

Trim engine to full “Down” position. If trim indicator

needle is not at the bottom of the green arc on the

gauge face, tilt engine “up” to gain access to the trim

sender. Loosen screws and reposition trim sender, as

shown. Trim engine to full “Down” position and re-

check needle position.

22744

a

b

c

d

e

a-Trim Sender

b-Screws, Loosen to Rotate Sender

c-Turn Sender Counterclockwise to Raise Needle Reading

d-Turn Sender Clockwise to Lower Needle Reading

e-Tilt Lock Lever

Motor Repair

REMOVAL

NOTE:

Power Trim assembly does not have to be re-

moved from engine to repair motor.

Remove motor and pump as an assembly; refer to

“Pump Replacement,” preceding.

DISASSEMBLY

Refer to “Pump Replacement,” preceding, for proper

disassembly procedure.

CLEANING AND INSPECTION

Inspect O-rings, and replace if damaged.

Clean, inspect and test motor components; refer to

“Brush Replacement,” “Armature Test,” and “Field

Tests,” preceding.

Loading...

Loading...