6A-36 POWER TRIM 90-13645--2 495

MOTOR DISASSEMBLED

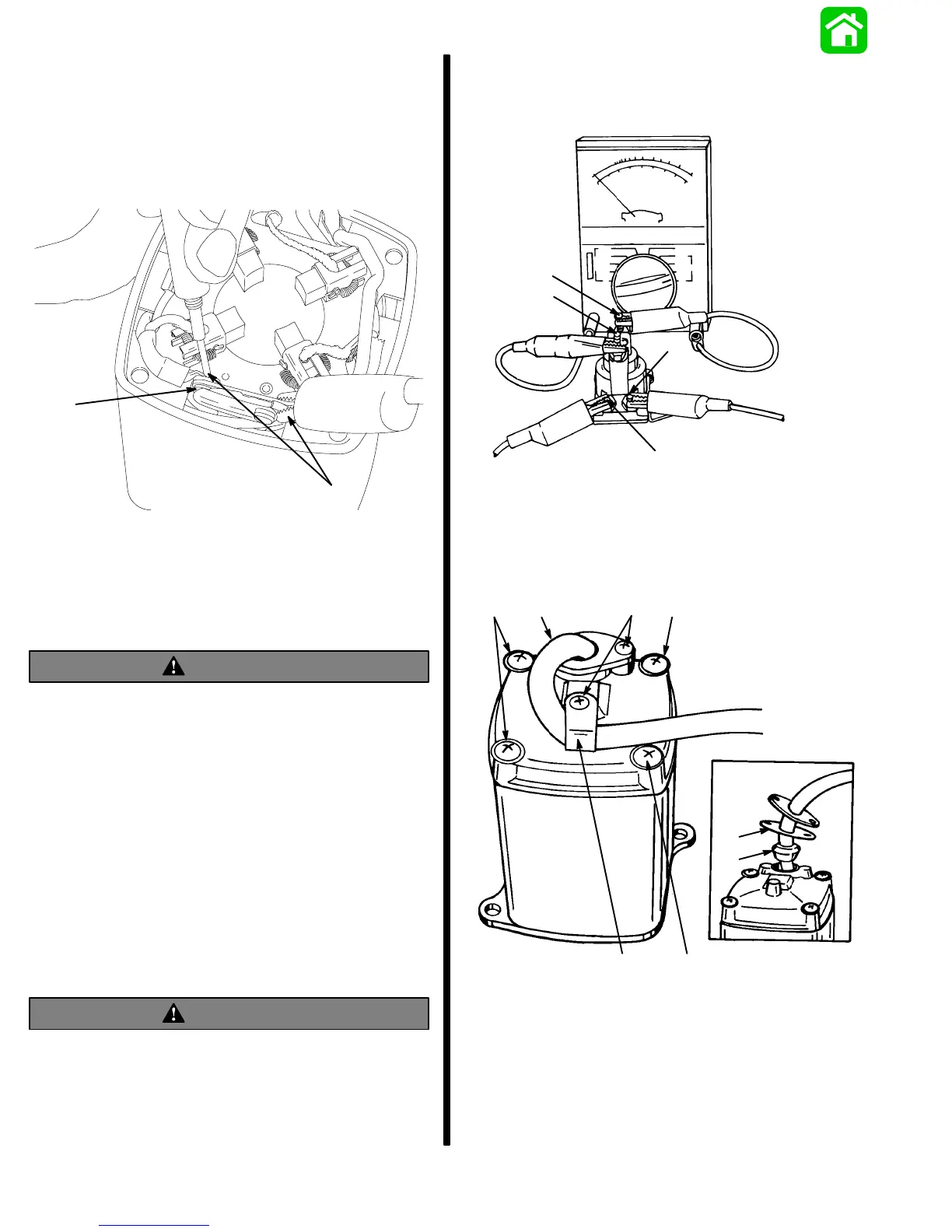

Connect Ohmmeter (R x 1 scale) leads as shown. If

switch is good, full continuity (zero ohms) will be

indicated.

If full continuity is not indicated, clean switch contact

surfaces, using an ignition point file.

18473

a

b

c

d

c - Test Leads

d - Switch Contact Surface

Recheck switch; if full continuity is not indicated, re-

place brush card. Switch is supplied on brush card.

Trim Pump Motor Test

WARNING

Do not perform this test near flammables (or

explosives), as a spark may occur when making

connections.

1. Disconnect BLUE (motor) wire and BLACK (mo-

tor) wire at solenoids.

2. Connect a 12-volt supply to motor wires [POS-

ITIVE (+) wire to BLUE (motor) wire, and NEG-

ATIVE (–) wire to BLACK (motor) wire]. Motor

should run.

3. If motor does not run, disassemble motor and

check components. Refer to “Motor Repair,”

following.

Solenoid Test

WARNING

Do not perform this test near flammable materials,

as a spark may occur while making electrical

connections.

1. Disconnect all wires from solenoid terminals.

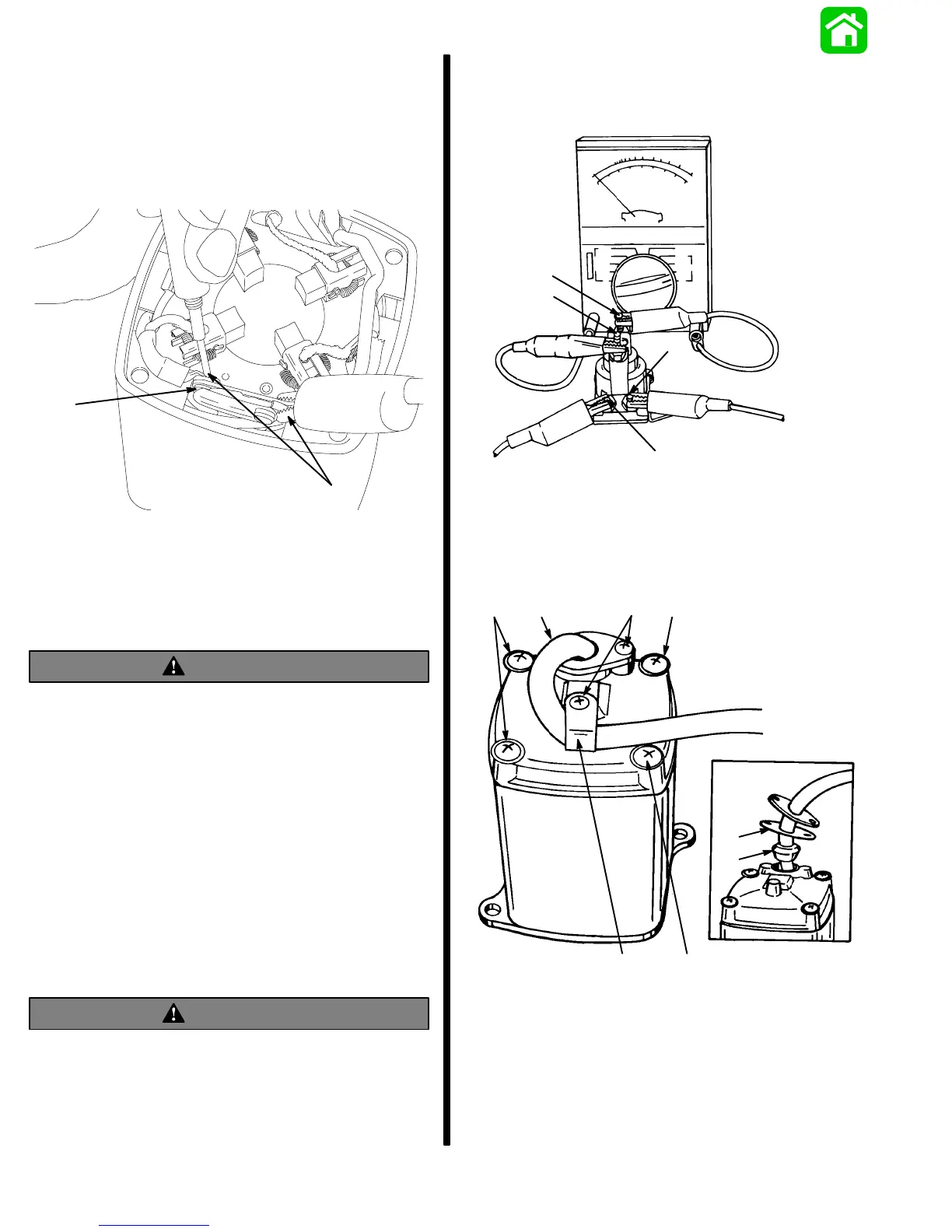

2. Set an Ohmmeter to R x 1 scale and connect me-

ter leads to solenoid terminals 1 and 2.

3. Connect a 12-volt power supply to terminals 3 and

4. Solenoid should click and meter should read

zero (0) ohms (full continuity).

51338

1

2

3

4

4. If meter does not read zero (0) ohms, replace

solenoid.

Motor Disassembly

1. Remove screws and clamp.

a

51345

a

b

d

e

a

b

c

a - Screw (4)

b - Screw (3)

c - Clamp

d - Gasket

e - Grommet

Loading...

Loading...