90-13645--2 495 6B-7POWER TRIM

TO PURGE:

IMPORTANT: Fill plug and O-ring must be tight-

ened securely before purging system.

IMPORTANT: Run Trim System in short “jogs” un-

til pump is primed and trim system moves. If trim

motor is run without priming pump, driveshaft

failure could result.

Cycle outboard through entire trim/tilt range 4 times.

Check fluid level after purging system.

Push down on outboard when trim rams are slightly

extended. If rams retract more than 1/8 in. (3.2 mm),

air is present in system. Cycle system again and

check fluid level.

TO CHECK:

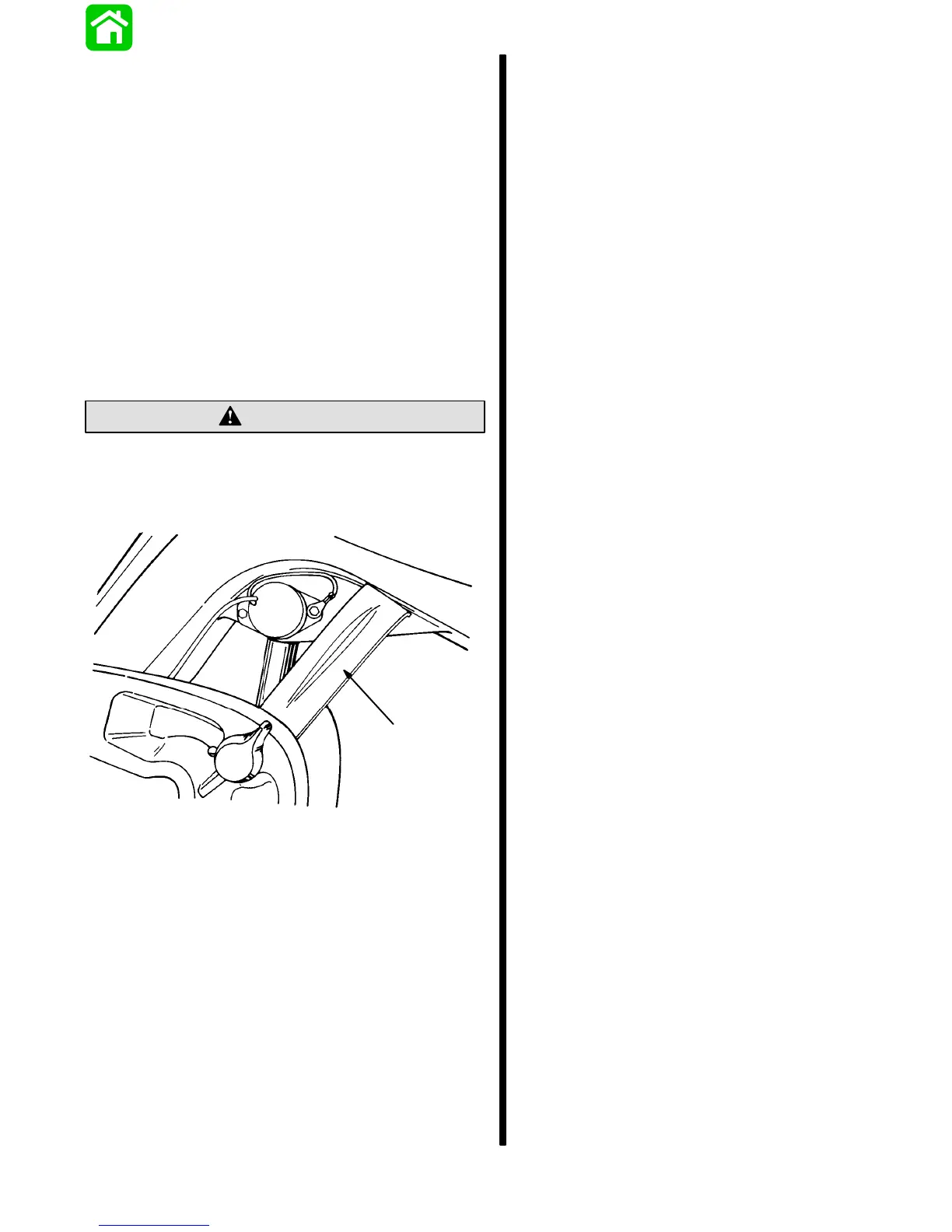

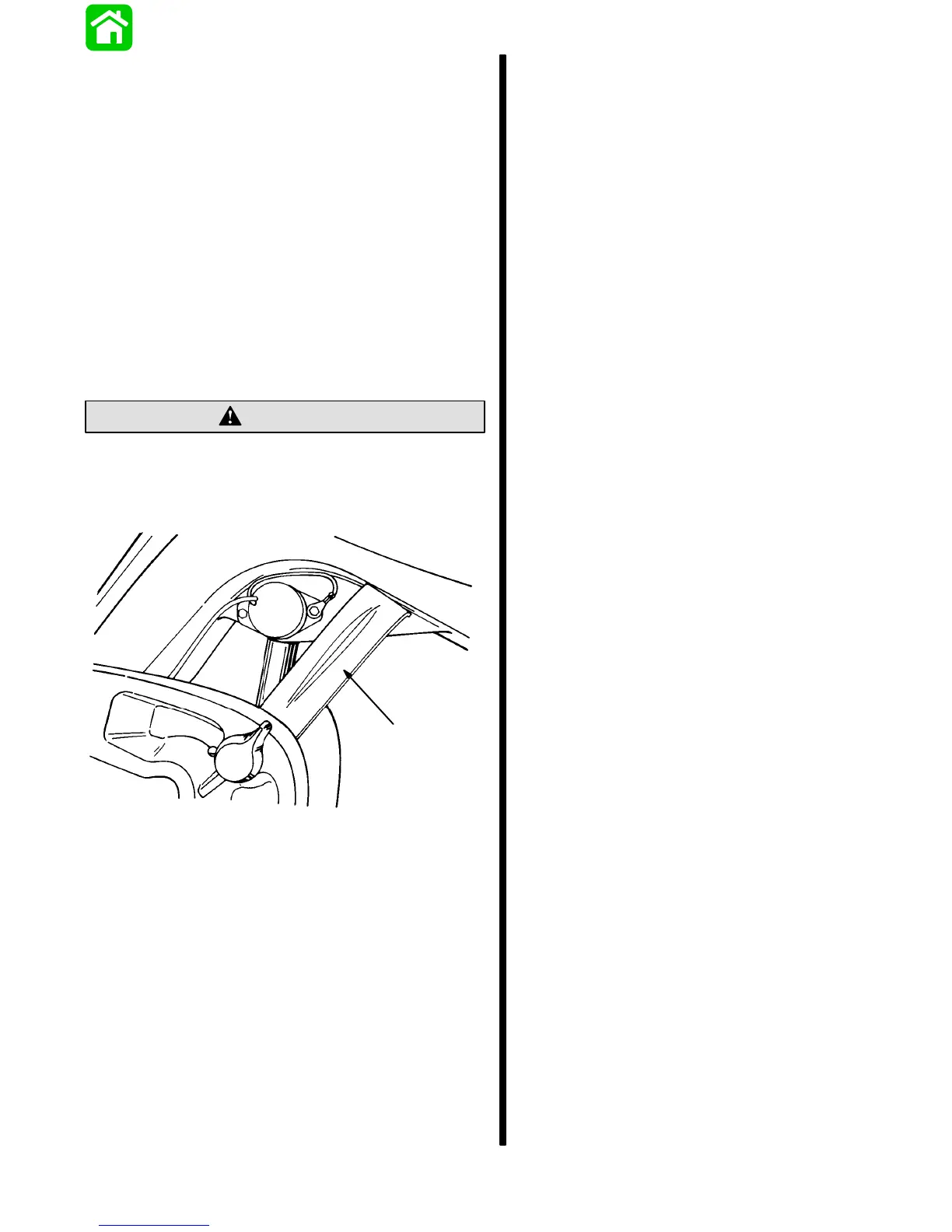

Tilt outboard to full “Up” position and engage tilt

lock lever before checking fluid level. System is

pressurized. Extend trim and tilt rams fully to

depressurize system.

CAUTION

51368

a

a - Tilt Lock Lever (engage to support engine in “Up” position)

Remove fill plug and O-ring. System is full when oil

level is present at filler hole. Tighten fill plug securely.

Hydraulic System

Troubleshooting

IMPORTANT: Operate Power Trim System after

each check to see if problem is corrected. If prob-

lem has not been corrected, proceed to next

check.

1. Check that Manual Release Valve knob is tight-

ened to full right (clockwise) position.

2. Check trim pump fluid level and fill if necessary.

(Refer to “Fill, Check, and Purge - Power Trim

System”) preceding.

3. Check for external leaks in the system. Replace

defective parts if leak is found.

4. Check for air in the system and purge if neces-

sary. (Refer to “Fill, Check, and Purge - Power

Trim System”) preceding.

NOTE

: When troubleshooting the hydraulic system,

cleanliness, and inspection of sealing surfaces,

seals, O-rings, and moving parts is important. The in-

ternal pressures required for proper operation of the

Power Trim System require these parts to be in excel-

lent condition. Replace any parts that may be suspect

of failure.

Loading...

Loading...