Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 151 of 909

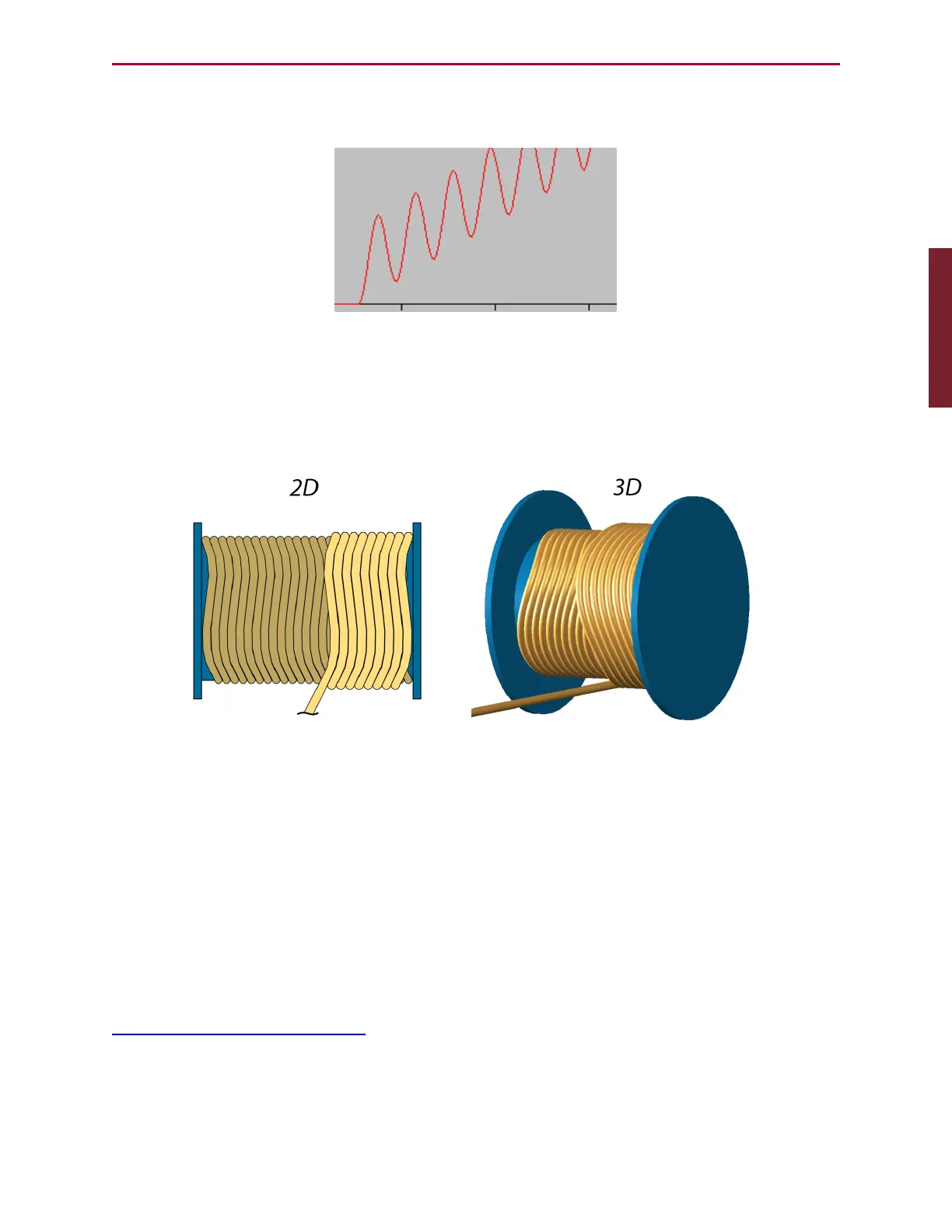

Note that camming can be linear, or cubic spline, which permits a smooth, high-frequency

oscillation on top of the low-frequency traverse. Refer to the following figure.

Smooth High-Frequency Oscillation

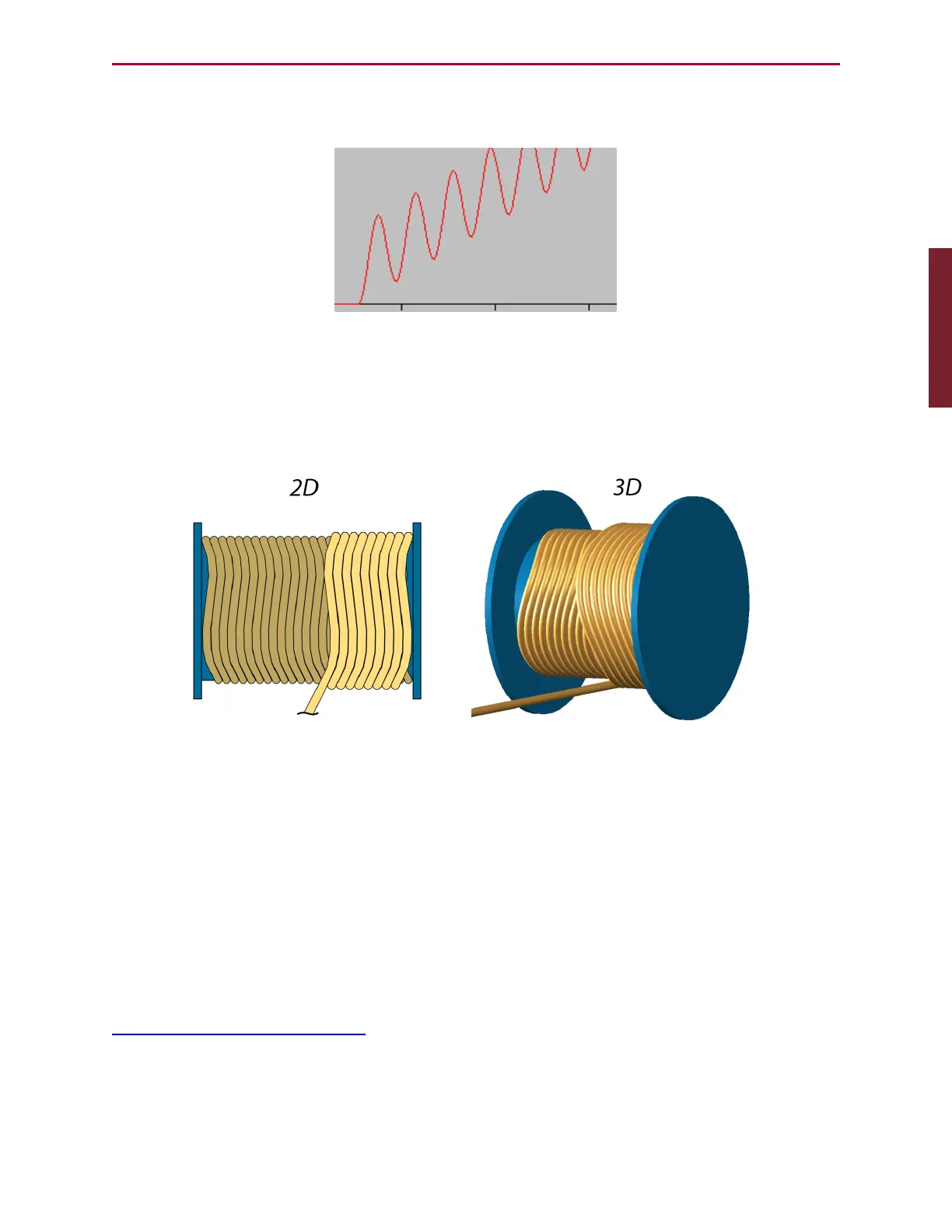

The overlapping "chevron" wraps are advantageous because they prevent the material from

becoming trapped in the windings of the underlying layer, which can cause it to be

pinched/kinked or break during removal. Either of those conditions would cause the spool to

be defective. Refer to the following figures.

To create this solution, the SmartMotor requires only four parameters:

'System parameters:

c=8000 'Master (External) Encoder resolution

'(counts per 360 deg turn of spool)

w=10000 'Spool width distance in encoder counts of traversing slave motor

'Chevron shape parameters:

n=1000 'Slave counts per full (360 deg) turn of master spool (pitch)

nn=1000 'Slave counts per half (180 deg) turn of master spool

'(amplitude of chevron)

The complete code example is available in Chevron Traverse & Takeup on page 838. For more

information on electronic camming, see CamMode (Electronic Camming) on page 153. Also,

see the Fixed Segment Cam Simulator (on the Moog Animatics website, in the folder

http://www.animatics.com/tools), which is a gearing/camming training aid.

Part 1: Programming: Chevron Wrap Example

Loading...

Loading...