Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 624 of 909

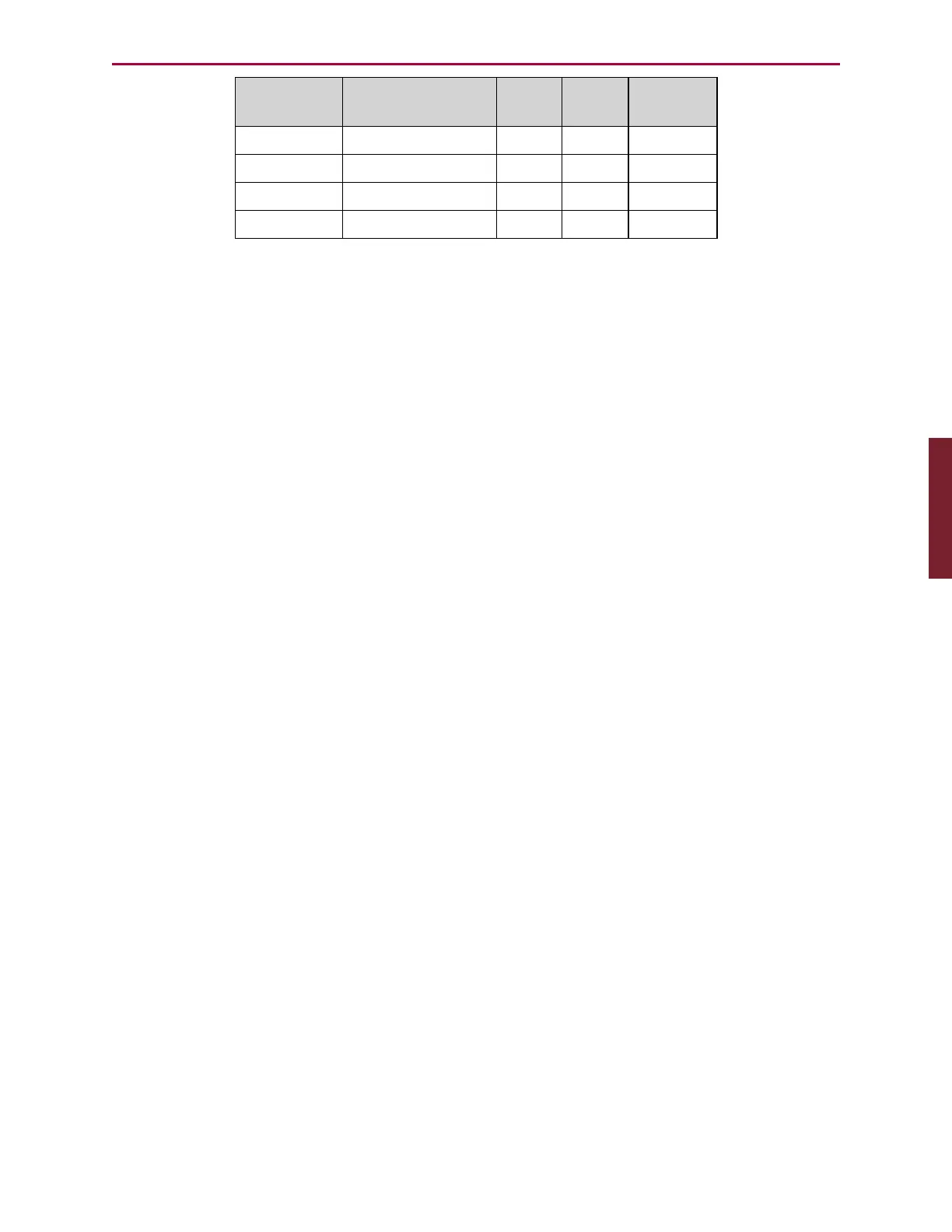

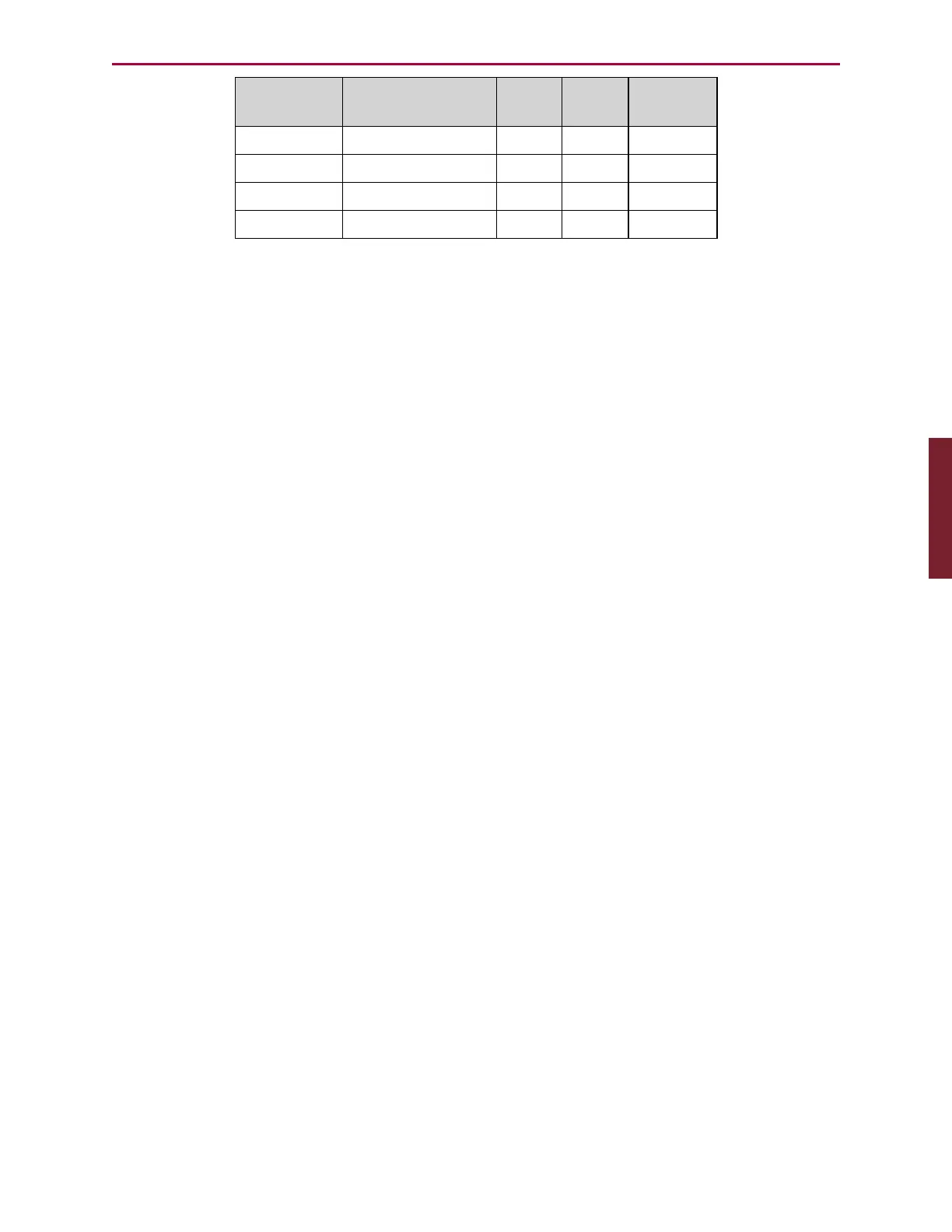

Command

PID / Trajectory

Update Rate

Period

(µsec)

SAMP

Report

RSP

Report

PID1 16 kHz 62.5 16000 06250/5...

PID2 8 kHz (default) 125 8000 12500/5...

PID4 4 kHz 250 4000 25000/5...

PID8 2 kHz 500 2000 50000/5...

EXAMPLE: (comparison of the different PIDvalues)

'For a 4000 count encoder SmartMotor:

'Using three fixed values under each of the PID settings

v=655360 'use to Set commanded Velocity (4000 count encoder)

a=256 'use to Set commanded Acceleration

w=1000 'use to set Wait time

PID1 'Default PID updates every servo sample

WAIT=w 'Wait time = 1 second

VT=v 'Velocity = 2400 RPM

ADT=a 'Accel/Decel = 250 RPS^2

PID2 'PID updates every 2 servo samples

WAIT=w 'Wait time = 1 second

VT=v 'Velocity = 1200 RPM

ADT=a 'Accel/Decel = 62.5 RPS^2

PID4 'PID updates every 4 servo samples

WAIT=w 'Wait time = 1 second

VT=v 'Velocity = 600 RPM

ADT=a 'Accel/Decel = 15.625 RPS^2

PID8 'PID updates every 8 servo samples

WAIT=w 'Wait time = 1 second

VT=v 'Velocity = 300 RPM

ADT=a 'Accel/Decel = 3.9063 RPS^2

PID2 'Return to Default PID

WAIT=w 'Wait time = 1 second

END

In the previous example, although the values used for Velocity, Acceleration/Deceleration,

and Wait times remained the same, their effect was changed by the PID setting. As a result,

much care should be taken if changes are made in the middle of a program.

While the motor is motionless, the PID parameter can be changed from PID1 to PID8, to

increase I/O scanning efficiency or other code execution, and then returned to PID1 just

before the next move. This is a technique used to increase response time for input triggers or

mathematical calculations when there is no trajectory in progress.

Part 2: Commands: PID#

Loading...

Loading...