Spitfire – Maintenance Manual

255

AP-74096, Rev. 1.0, 09/06/05

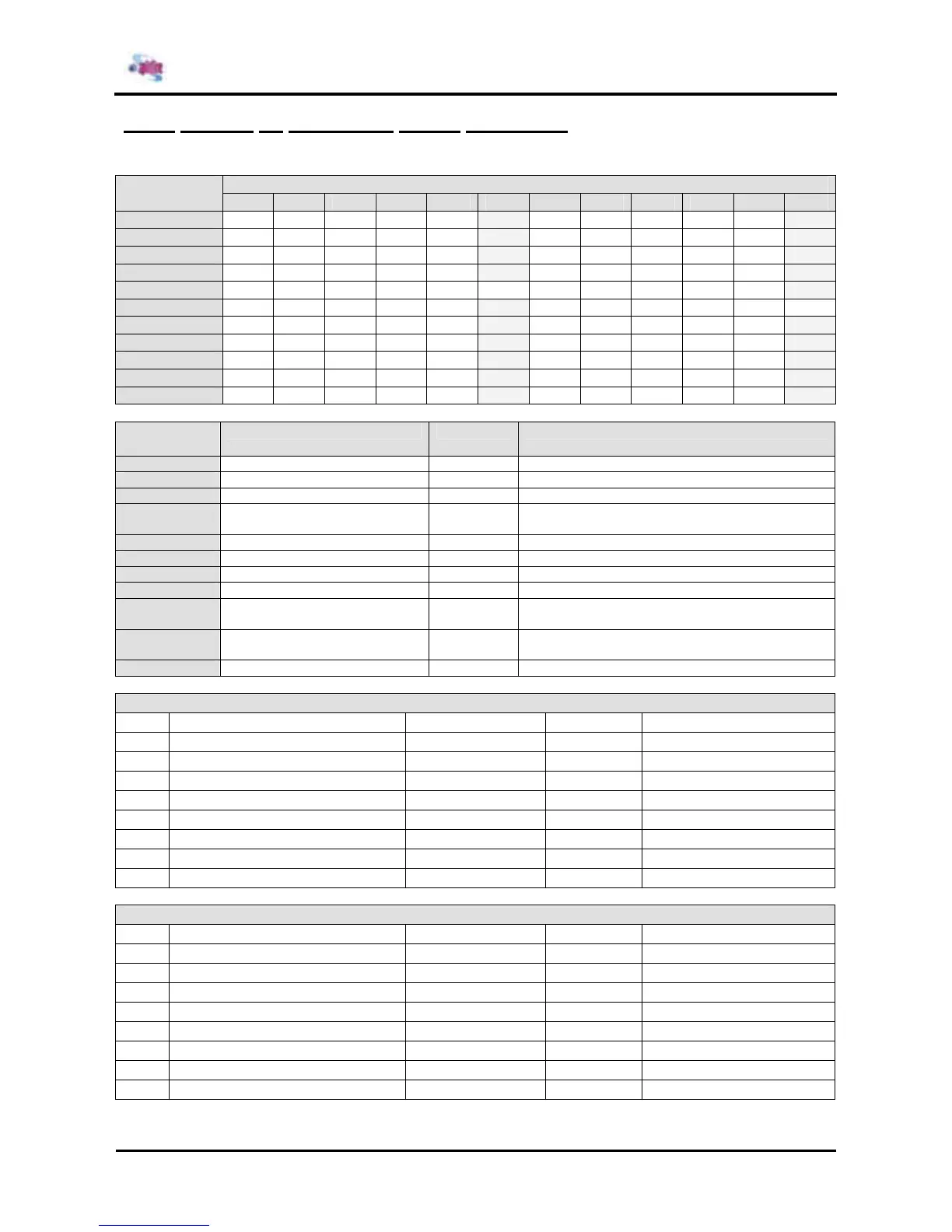

8.3.2. Service by authorised Mutoh technician

Perform periodical inspections according to the table below.

Month Maintenance

Cycle

1 2 3 4 5 6 7 8 9 10 11 12

10

X X

11

X X

12

X X

13

X X

14

X

15

X

16

X X

17

X X

18

X X

19

X X

20

X X

Maintenance

Cycle

Part number Quantity Action

10

MY-42110 8 Change dampers

11

MY-80300L 2 Change pumps (*)

12

ME-80035 4x0,8m Change tubes from pumps -> Waste bottle

13

DE-35085 + ME-80040 + ME-

60014

1 + 1m + 1 Change spitting box + tube + L connection

14

MY-80627 1 Change capping station

15

MY-80622 1 Change cap assy capping station

16

KY-80050 as required Apply grease on head up-down cams when needed

17

KY-80050 as required Apply grease on Y-motor belt when needed

18

KY-80050

as required

Apply grease on roller path – carriage when

needed (**)

19

KY-80050

as required

Apply grease on capping station camm + gears

when needed

20

- as required

Dust removal in fan area underneath print platform

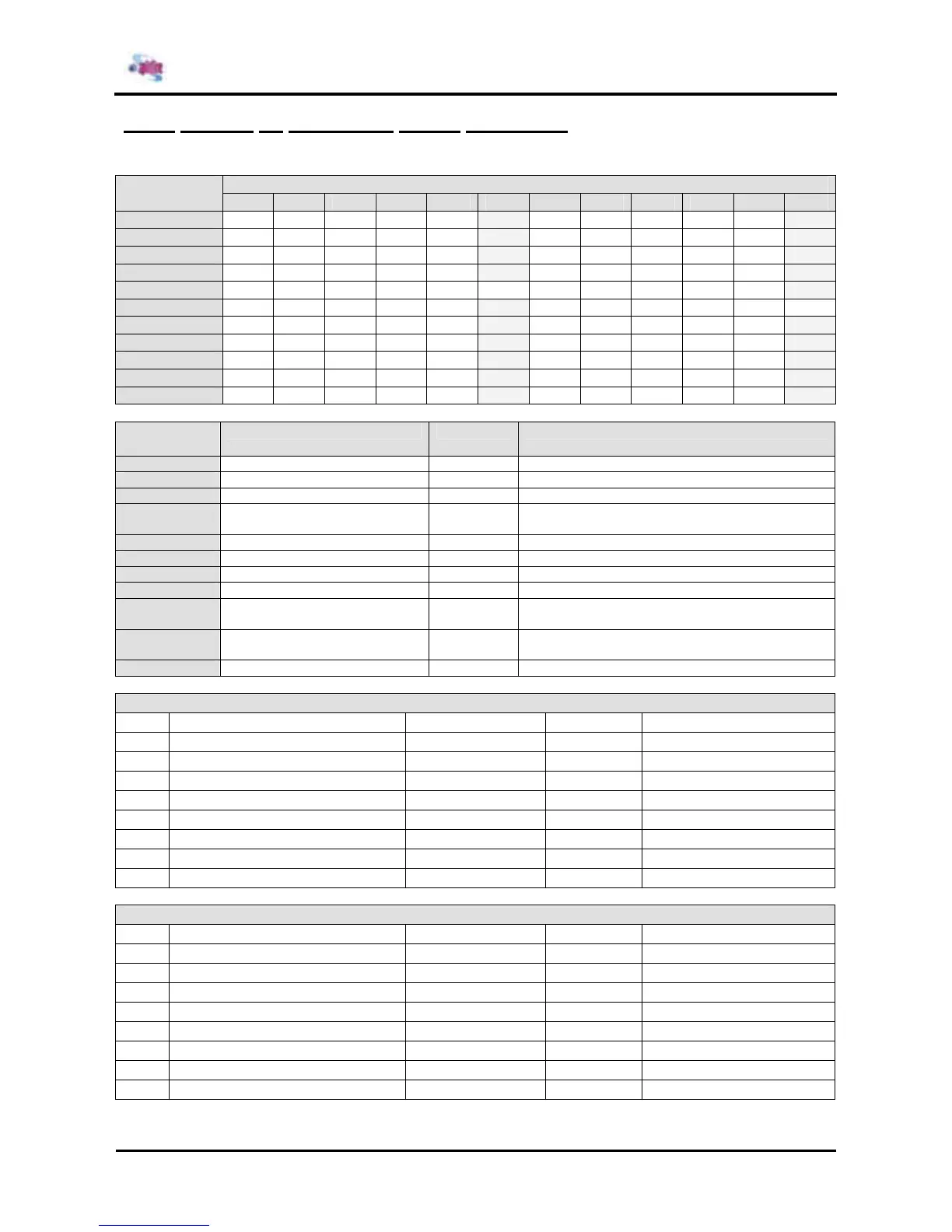

maintenance cycle Kit 6 months (KY-80226)

Description

Partnr.

# Needed for : (Cycle)

1 Dampers MY-42110 8x 10

2 Pumps MY-80300L 2x 11

3 Tubing pumps ME-80035 3,2meter 12

4 Spitting box DE-35085 1x 13

5 Tubing ME-80040 1meter 13

6 L connection ME-60014 1x 13

7 Cap assy capping station MY-80622 1x 15

8 Grease for maintenance cycle KY-80050 1x 16 to 20

maintenance cycle kit 12 months (KY-80227)

Description

Partnr.

# Needed for : (Cycle)

1 Dampers MY-42110 8x 10

2 Pumps MY-80300L 2x 11

3 Tubing pumps ME-80035 3,2meter 12

4 Spitting box DE-35085 1x 13

5 Tubing ME-80040 1meter 13

6 L connection ME-60014 1x 13

7 Capping station MY-80627 1x 14

8 Grease for maintenance cycle KY-80050 1x 16 to 20

Loading...

Loading...