4 ENGIN E SY M PTOMS DIAGNOSTICS 107

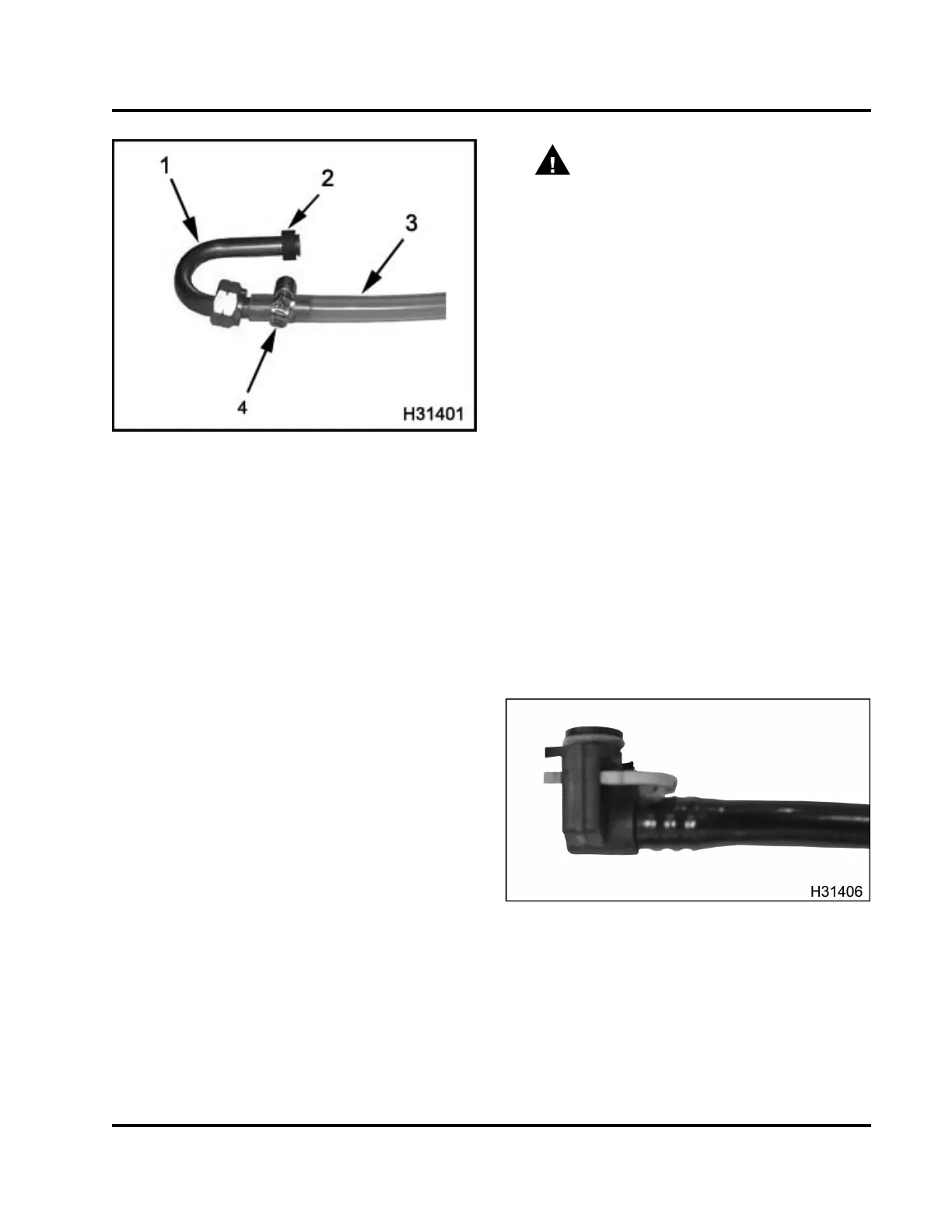

Figure 120 Test fuel line

1. F uel line

2. Sleeve seal

3. Clear plastic tube

4. Clamp

2. Make a test fuel line.

• Use spare fuel line. (Make sure the sleeve

seal is in good condition.) Cut the line in half.

Use the test fuel line p ortion that supplies the

fuel pump. Install clear plastic line in place of

removed section and secure plastic line with

aclamp.

NOTE: The mechanic is expected to keep the fuel

test line for future diagnostics. Expense the fuel

test line as an essential tool and keep it with other

diagnostic tools. Warranty will not cover the cost

of the fuel test line.

3. Connect the fuel test line between the fuel pump

inlet and an alternate fuel source.

WARNING: To avoid serious personal

injury, possible death, or damage to the

engine or vehicle – comply with the following:

When routing test line, do not crimp the line,

run the line too close to moving parts, or let

the line touch hot engine surfaces.

4. Start or crank the engine for 20 seconds. Measure

fuel pressure with the shut-off valve closed. Open

the shu t-off valve to check for aera tion.

NOTE: Breaking any fuel system joint will induce

air into the fuel system. The air should pass in a

short period of time. As fuel pressure is relieved, a

steady stream of fuel without air bubbles indicates

the fuel is not aerated.

• If the fuel is aerated, go to “Combustion Leaks

to Fuel” (page 108) in this section.

• If the fuel is not aerated, remove test setup

from the fuel pump inlet. Connect the fuel

pump supply lin e. Go to “Alternate F uel

Source Supply to Fuel Filter Housing” in this

section.

Alternate Fuel Source Supply to Fuel Filter

Housing

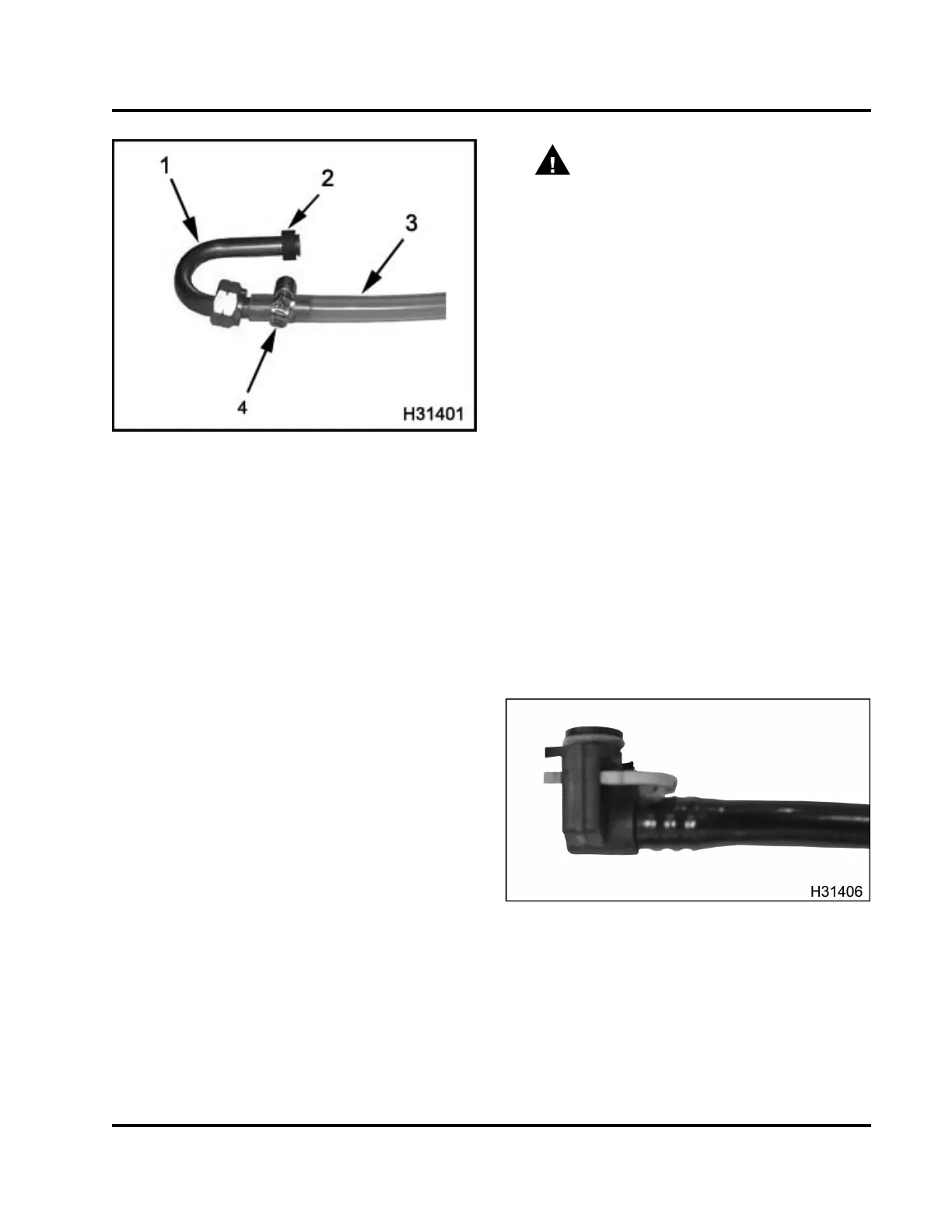

Figure 121 Fuel filter inlet test line

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© August 2008 Navistar, Inc.

Loading...

Loading...