7 ELECTRONIC CONTROL SYSTEMS DIAGNOSTICS 351

CKP Sensor (Crankshaft Position)

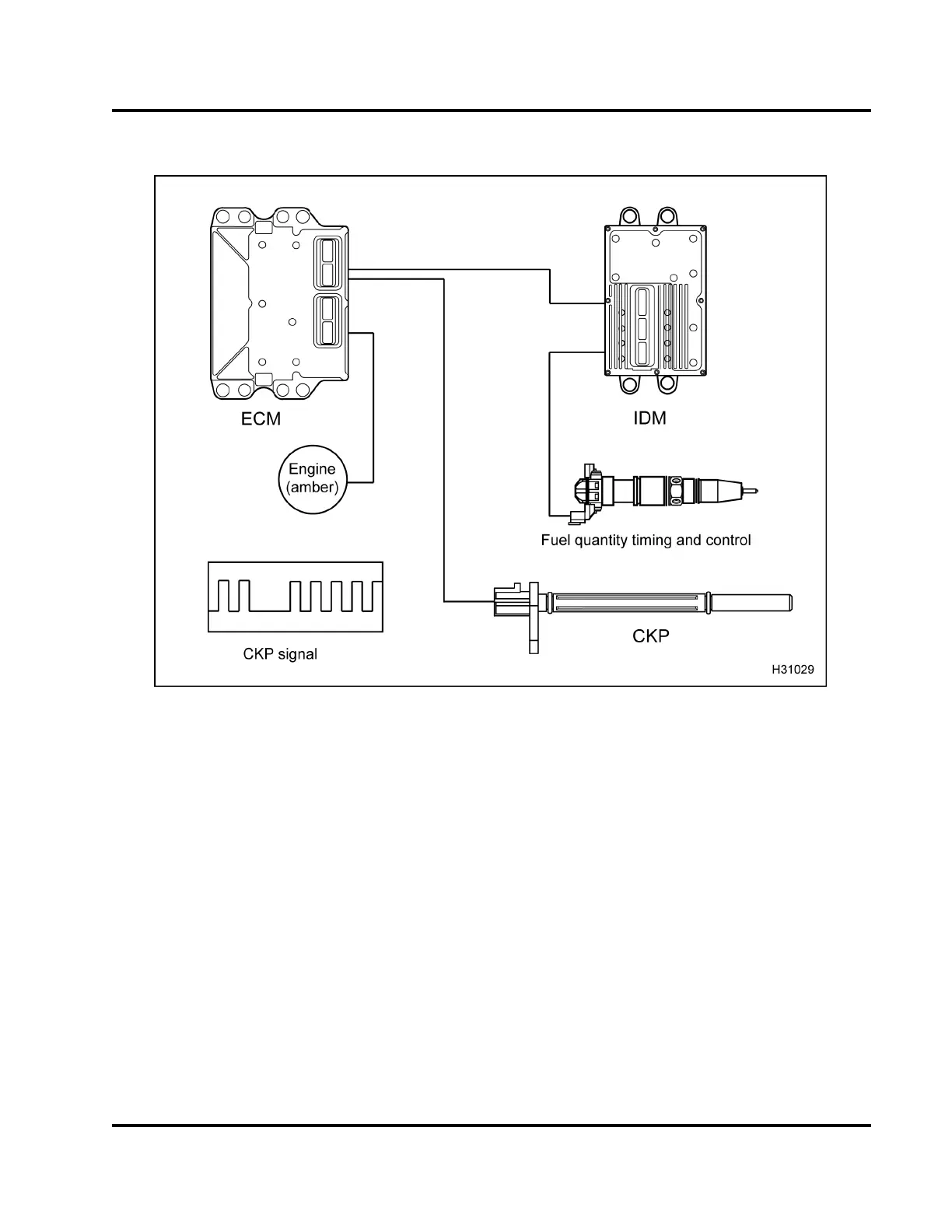

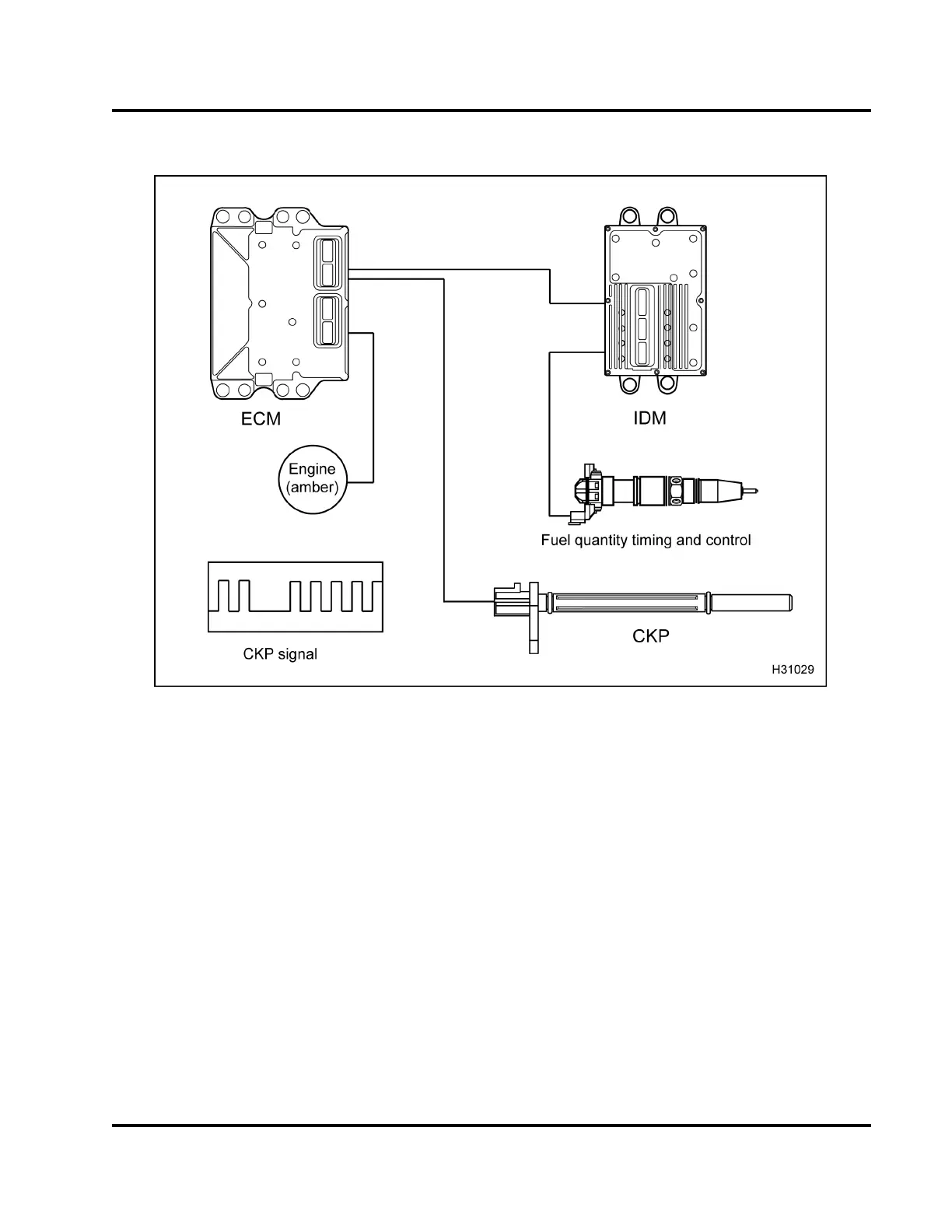

Figure 406 Function diag

ram for the CKP sensor

The function diagram f

or the CKP sensor includes the

following:

• CKP sensor

• Electronic Control M

odule (ECM)

• Injector Driver Modu

le (IDM )

• Fuel injector

• ENGIN E lamp (am ber)

Function

The C KP sensor provid

es the ECM with a signal

that indicates cran

kshaft speed and position. As the

crankshaft turns th

e CKP sensor detects a 60 tooth

timing disk on the

crankshaft. Teeth 59 and 60 are

missing. By comp

aring the CKP signal with the CMP

signal, the ECM c

alculates engine rpm and timing

requirements. The CKP

is installed in the top left sid e

of the flywheel housing

.

The sensor produces p

ulses for each tooth edge

that pa sses it. Cran

kshaft speed is derived from the

frequency of the CK

P sensor signal. The crankshaft

position is determ

ined by synchronizing the SYNC

toothwiththeSYN

C gap signals from the target

disk. From the CK

P signal frequency, the ECM

can calculate e

ngine rpm and timing requirements.

Diagnostic in

formation on the CKP input signal

is obtained by

performing accuracy checks on

frequency, a

nd duty cycle with software strategies.

NOTE: The lon

g CKP sensor, used with

Internation

al® DT 466, DT 570, and HT 570

diesel engi

nes, is the Camshaft Position (CMP)

sensor use

d with other International® diesel engines.

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© August 2008 Navistar, Inc.

Loading...

Loading...