7 ELECTRONIC CONTROL SYSTEMS DIAGNOSTICS 495

IPR Circuit Operation

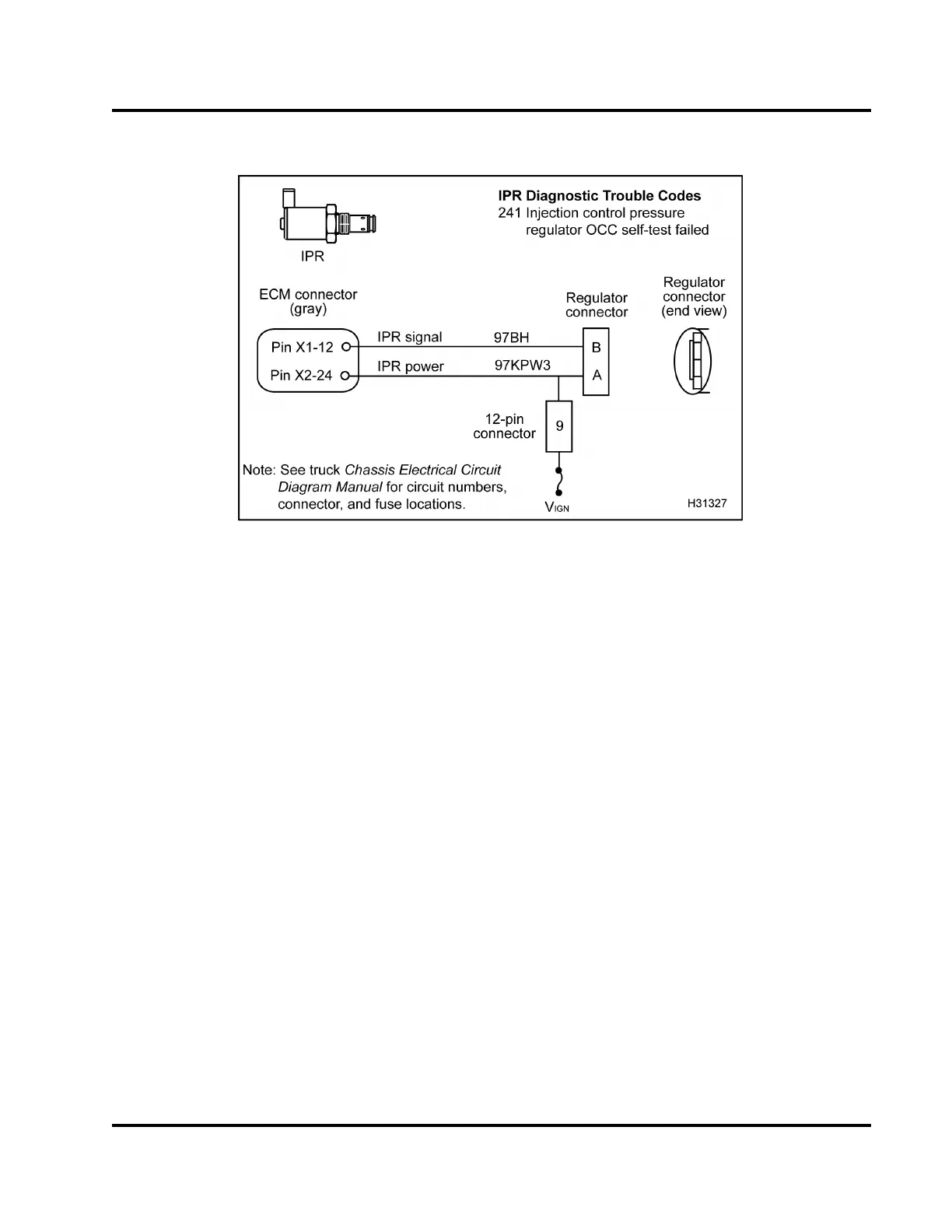

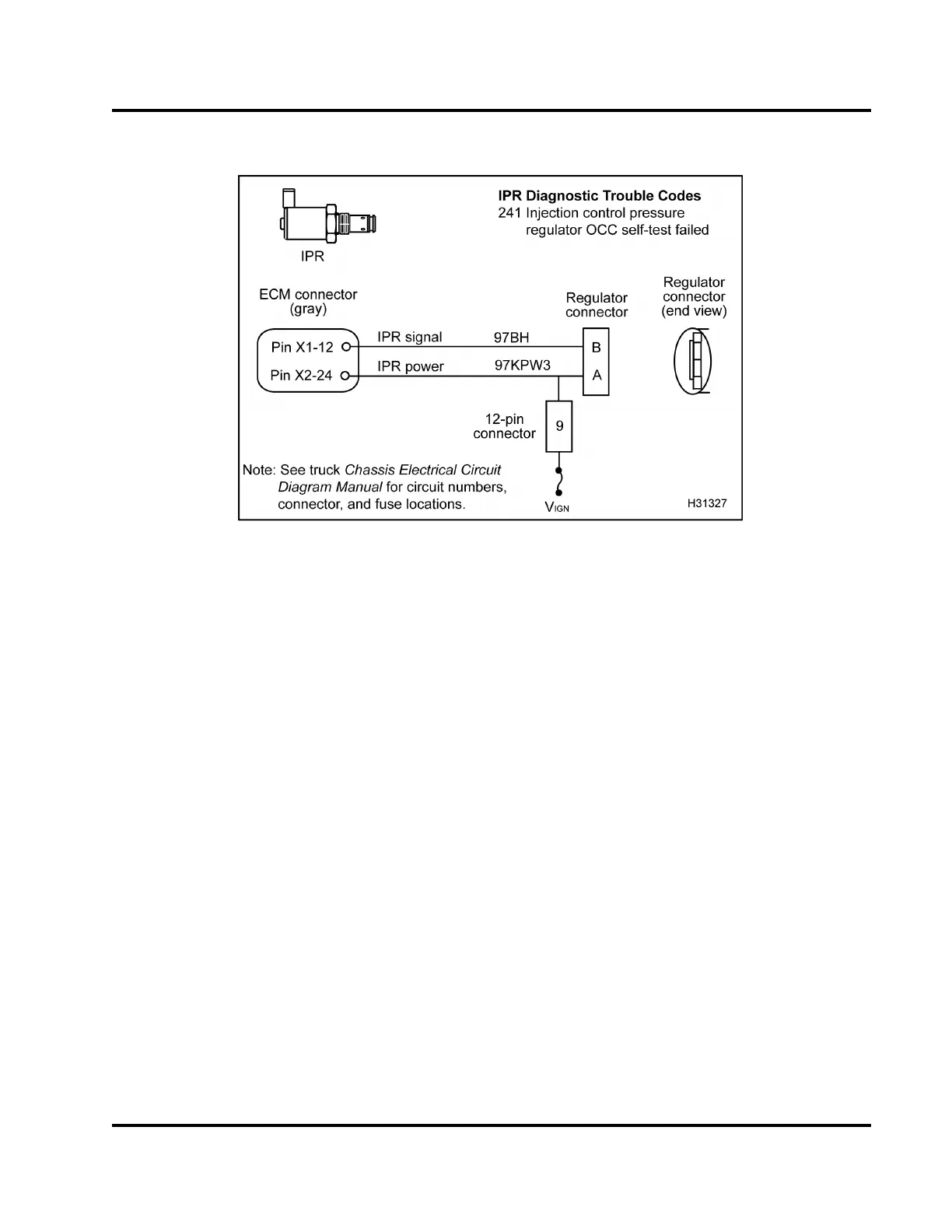

Figure 481 IPR circuit diagram

The IPR valve is supp lie d with vo

ltage at Pin A of

the IPR connector through 12–p

in connector (Pin 9)

from V

IGN

. The control of the i

njection control system

is gain ed by the ECM grounding

Pin B of the IPR

valvethroughPinX1-12ofth

e ECM. Precise control

is gained by varying the p

ercentage of ON/OFF time

of the IPR solenoid . A hig

h duty cycle indicates a

high amount of injectio

n control pressure is being

commanded. A low duty c

ycle indicates less pressure

being commanded.

Fault Detection / Ma

nagement

An open or short to gro

und in the ICP control circuit

can be detected by an

on demand output circuit

check during KOEO S

tandard Test. If there is a circuit

fault detected a Di

agnostic Trouble Code (DTC) will

be set. When the en

gine is ru nn ing, the E CM can

detect if the inj

ection control pressure is equal to

the desired pre

ssure. When the measured injection

control p ress

ure does not compare to the desired

pressure, the

ECM will ignore the measured ICP

signal and co

ntrols the engine with the desired value.

IPR Diagnost

ic Trouble Codes (DTCs)

DTCs are read

using the EST or by counting the

flashes from

the amber and red ENGINE lamp.

DTC 241

IPR OCC self-test failed

• DTC 241 is set by the ECM when the O u

tput

Circuit Check (OCC) test has fai

led after the

KOEO Standard Test has been r

un.

• DTC 241 can be set when a poor co

nnection to

the IPR solenoid or inoperat

ive IPR coil e xists.

• When DTC 241 is active the eng

ine will not

run and the amber ENGINE lamp

will not be

illuminated.

Tools

• EST with MasterDiagnost

ics® software

• EZ-Tech® interface cable

• Digital Multimeter (DM

M)

• Breakout Box

• Actuator Breakout Harne

ss

• Terminal Te st Adapter Ki

t

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© August 2008 Navistar, Inc.

Loading...

Loading...