4 ENGIN E SY M PTOMS DIAGNOSTICS 115

Fuel in Coolant

Symptom

Coolant contaminated with diesel fuel will have a

diesel fuel odor.

Cause

• Leaking or cracked injector sleeve with injector

O-ring failure

• Cracked or porous h ea d c asting in fuel rail

cross-drillings.

Tools

• Regulated compressed air

• Fuel Test Fitting

• Fuel/Oil Pressure Test Coupler

• Cylinder head test plate

• Water supply housing pressure adapter

• Thermostat opening pressure adapter (cylinder

head)

Procedure

1. Verify coolant contamination.

• Check for diesel fuel odor in coolant.

• Coolant may be discolored if diesel fuel is

present.

CAUTION: Be sure to place a rag o r suitab le

container under the fuel pressure test valve

when bleeding the fuel rail. Dispose of fuel in a

correct container clearly marked DIESEL FUEL

according to local regulations.

NOTE: Engine fuel can be a threat to the

environment. N ever dispose of engine fuel

by putting it in the trash, pouring on the ground,

in the sewers, in streams, or bodies of water.

2. Plug in the cylinder block heater to warm coolant.

WARNING: To avoid serious personal injury,

possible death and damage to the engine:

• Always allow the engine to cool for 15

minutes.

• Wrap a thick cloth around the cap.

• Loosen cap slowly a quarter to half turn.

• Pauseforamomenttoavoidwaterorsteam

scalding.

• Contin ue to turn th e cap and remove.

• Never add cold coolant to a hot engine. This

can result in a cracked cylinder head or

crankcase.

• Never use water as a coolant substitute.

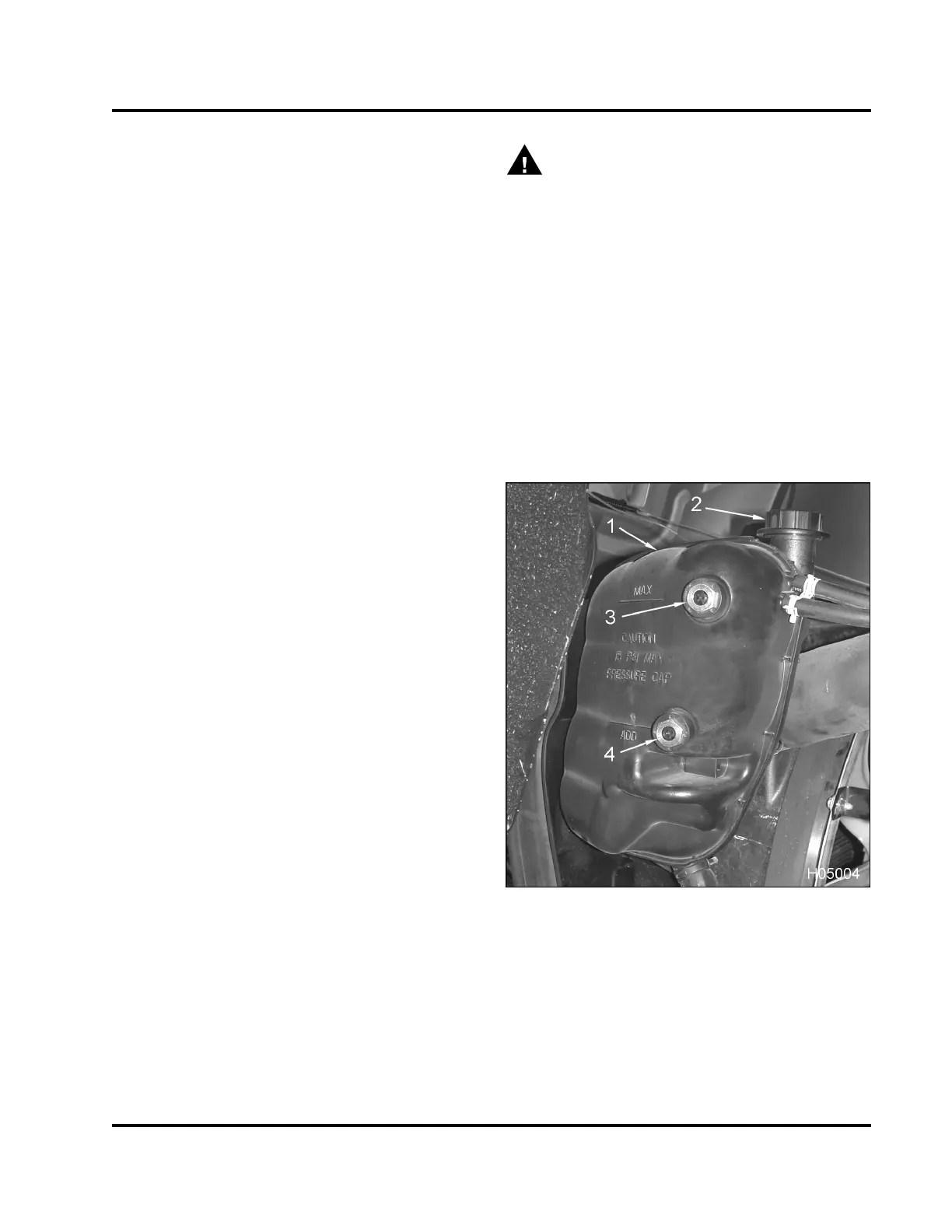

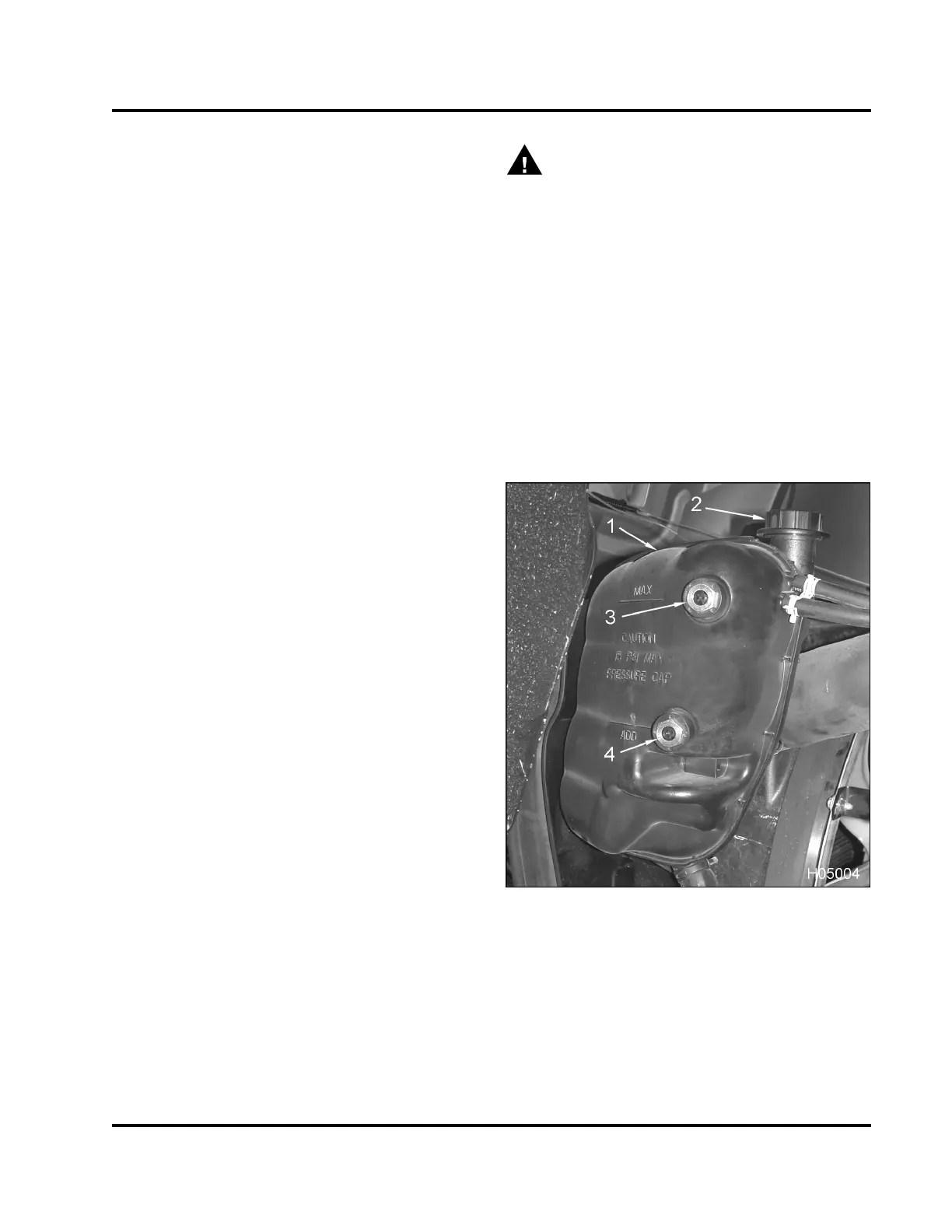

Figure 129 Deaeration tank fill position

1. Deaeration tank cap

2. Deaeration tank

3. MAXIMUM coolant level mark

4. ADD coolant level mark

3. Remove cap from deaeration tank and fill with

coolant to a level above the deaeration inlet line

to tan k .

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© August 2008 Navistar, Inc.

Loading...

Loading...