6 PERFORMANCE DIAGNOSTICS 277

Brake Lash

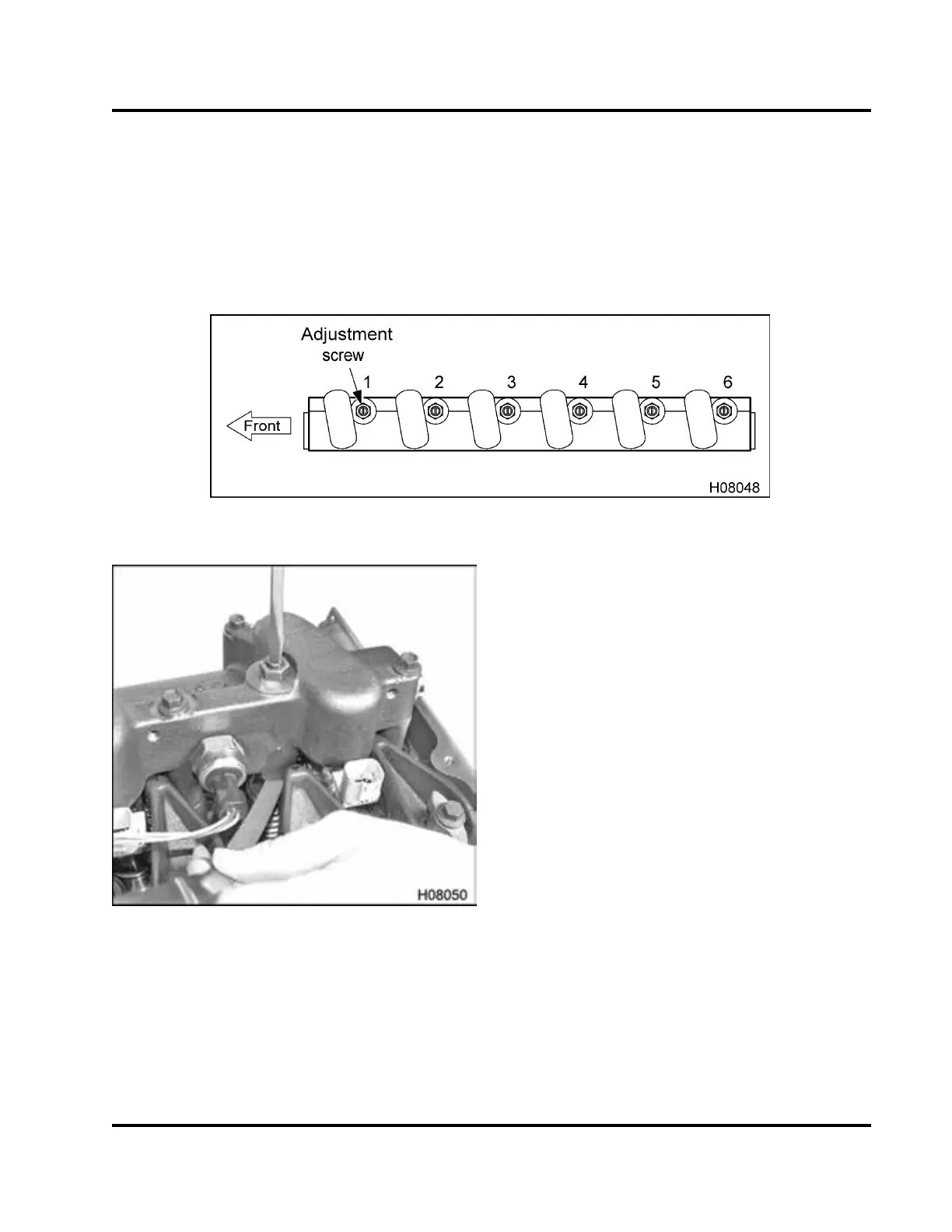

• Three actuators are adjusted when piston 1 is at

Top Dead Center (TDC) compression.

• Three actuators are adjusted when piston 6 is at

Top Dead Center (TDC) compression.

Corresponding intake and exhaust valve lash should

be adjusted before rotating the crankshaft.

Figure 361 Brake lash adjustment

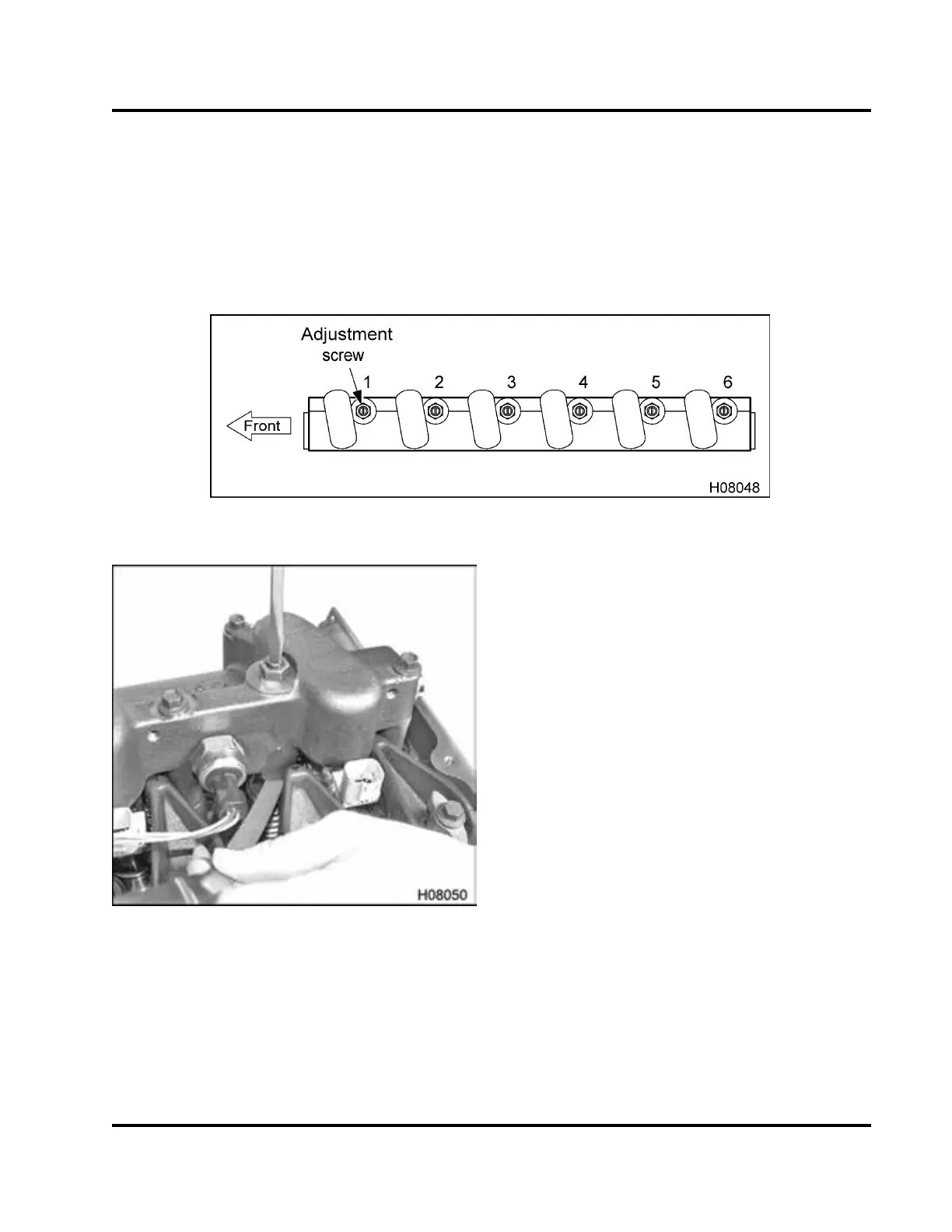

Figure 362 Feeler gauge between the valve

bridge and brake actuator

1. Check cold brake lash with a (0.019 in) feeler

gauge between the actuator and valve bridge. If

adjustment is required, loosen the locknut and

turn the actuator adjustment screw until a light

drag is felt.

2. Once bra k e lash is set , tighten the locknut to

27 N·m (20 lbf·ft) and remove the feeler gauge.

Recheck for light drag on feeler gauge. If drag is

too tight or loose, repeat steps 1 and 2.

Possible Causes

• Worn valve train

• Worn valve seat or valve face

• Worn actuator in Diamond Logic® engine brake

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©August 2008 Navistar, Inc.

Loading...

Loading...