276 6 PERFORMANCE DIAGNOSTICS

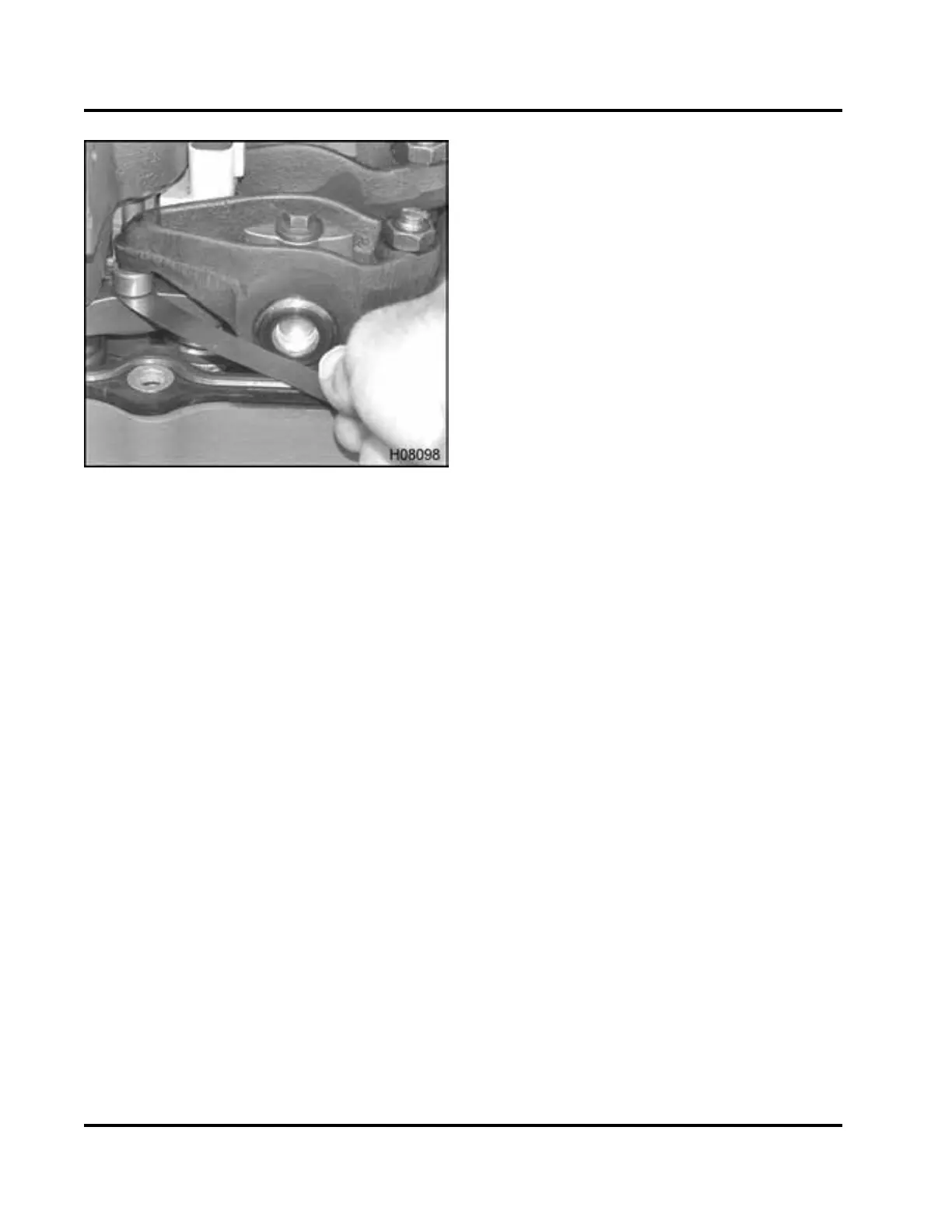

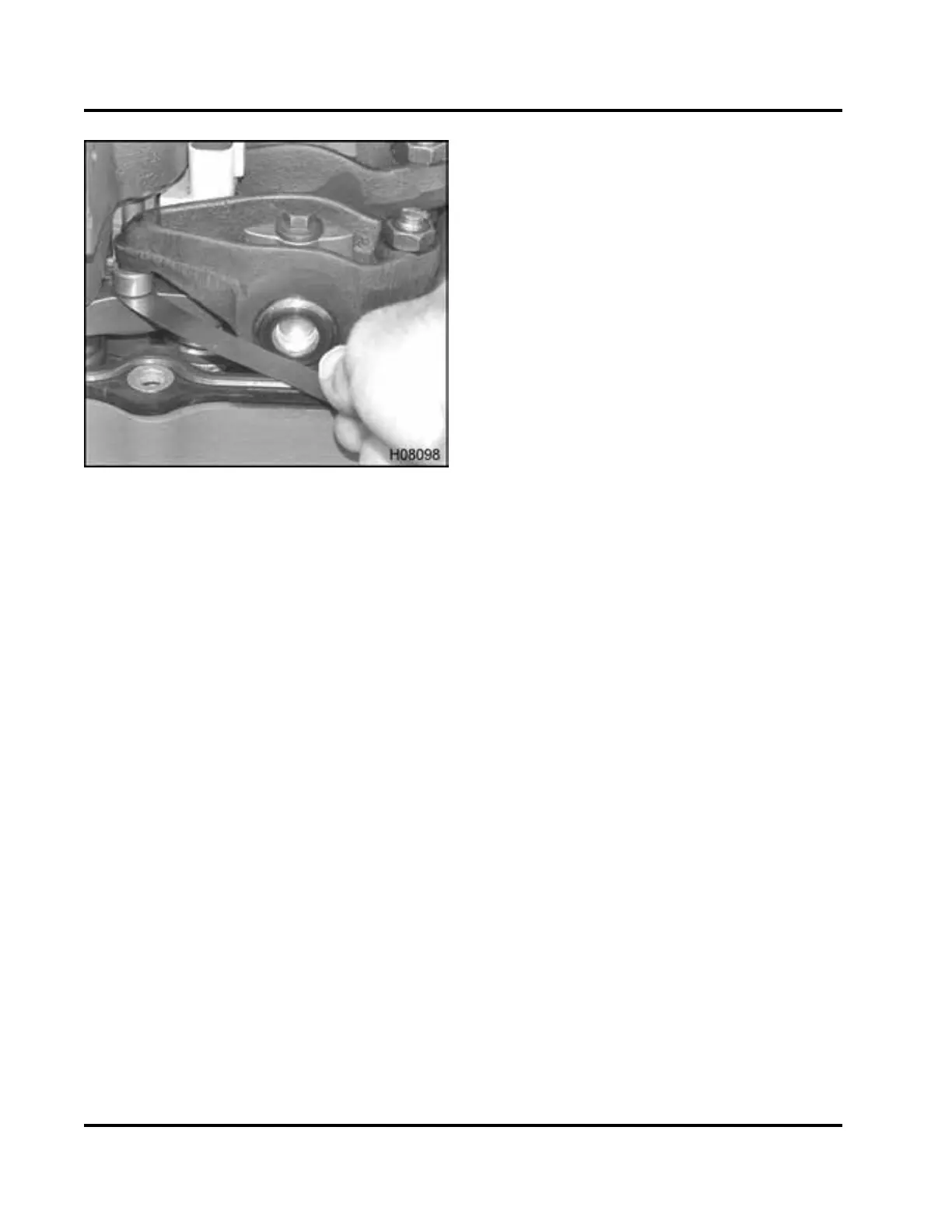

Figure 360 Feeler gauge between the pivot foot

and valve bridge

4. Check cold valve lash with a (0.019 in) feeler

gauge between the pivot foot and valve bridge.

If adjustment is required, loosen the locknut and

turn the valve adjustment screw until a light drag

is felt.

5. Once valve adjustment is set, tighten the locknut

to 27 N·m (20 lbf·ft) and remove the feeler gauge.

Recheck for light drag on feeler gauge . If drag is

too tight or loose, repeat steps 4 and 5.

If engine is equipped with the Diamond Logic®

engine brake, co rre s p onding brake actuator lash

can be adjusted before rotating the cra nk s h aft.

See “Brake Actu at or Lash” in this section .

6. Turn crankshaft 360° in the d irection of engine

rotation to remove gear lash from gear train and

realign the timing mark on the damper pulley with

the TDC ma rk on the fr ont cover.

•Iffirst adjustments were with piston 1 at T DC

compression, cylinder 6 should be at TDC

compression. Confirm that valves are closed

by making sure that push rods for cylinder 6

are loose and turn easily. If piston 6 is at TDC

compression, see and do steps 4 and 5.

•Iffirst adjustments were with piston 6 at T DC

compression, cylinder 1 should be at TDC

compression. Confirm that valves are closed

by making sure that push rods for cylinder 1

are loose and turn easily. If piston 1 is at TDC

compression, see and do steps 4 and 5.

Before doing step 7, If engine is equipped with

the Diamond Logic® engine brake corresponding

brake actuator lash can be adjusted. See “Brake

Actuator Lash” in this section.

7. Install valve cover following procedure in Engine

Service Manual.

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any proced ures.

Follow all warnings, cautions, and notes.

©August 2008 Navistar, Inc.

Loading...

Loading...