186 5 HARD START AND NO START DIAGNOSTICS

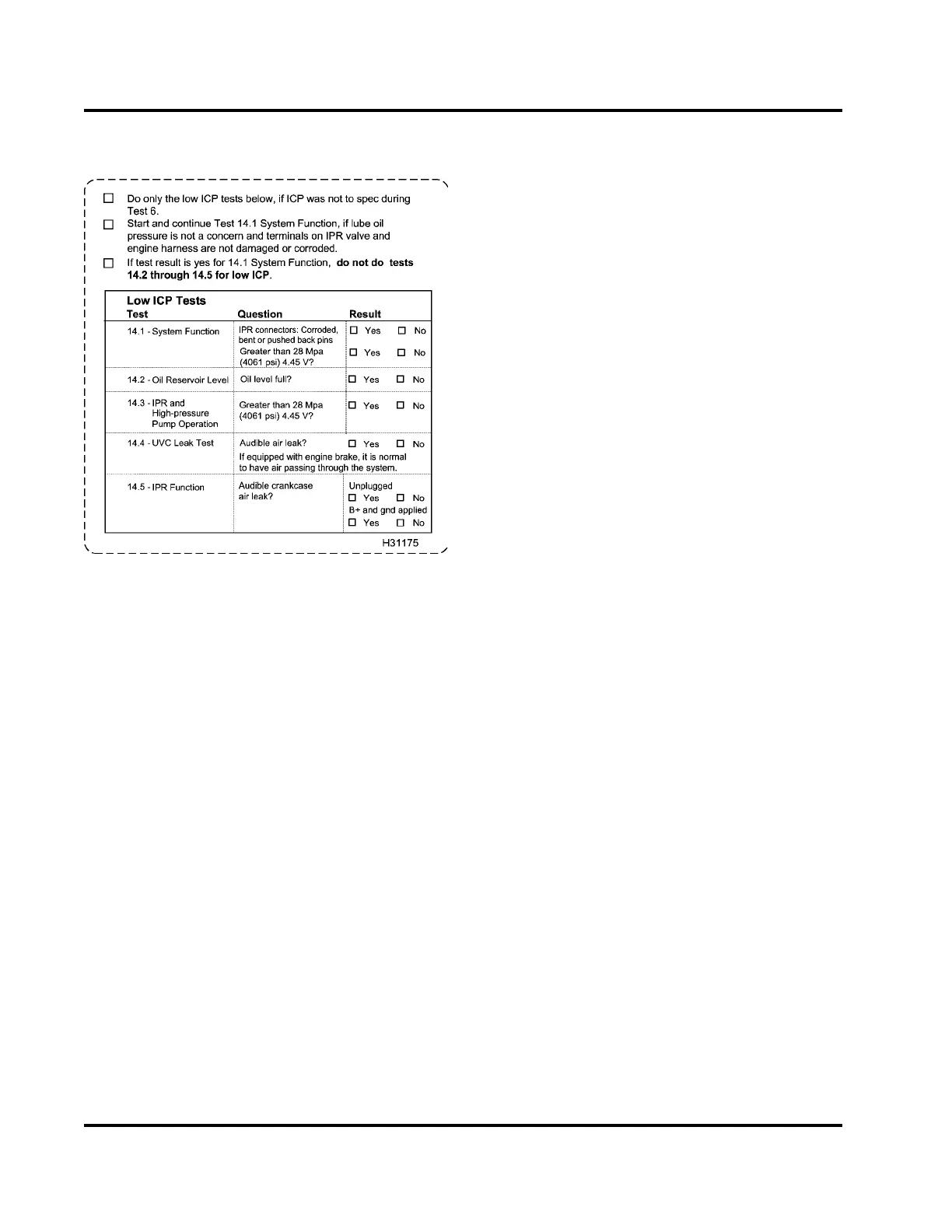

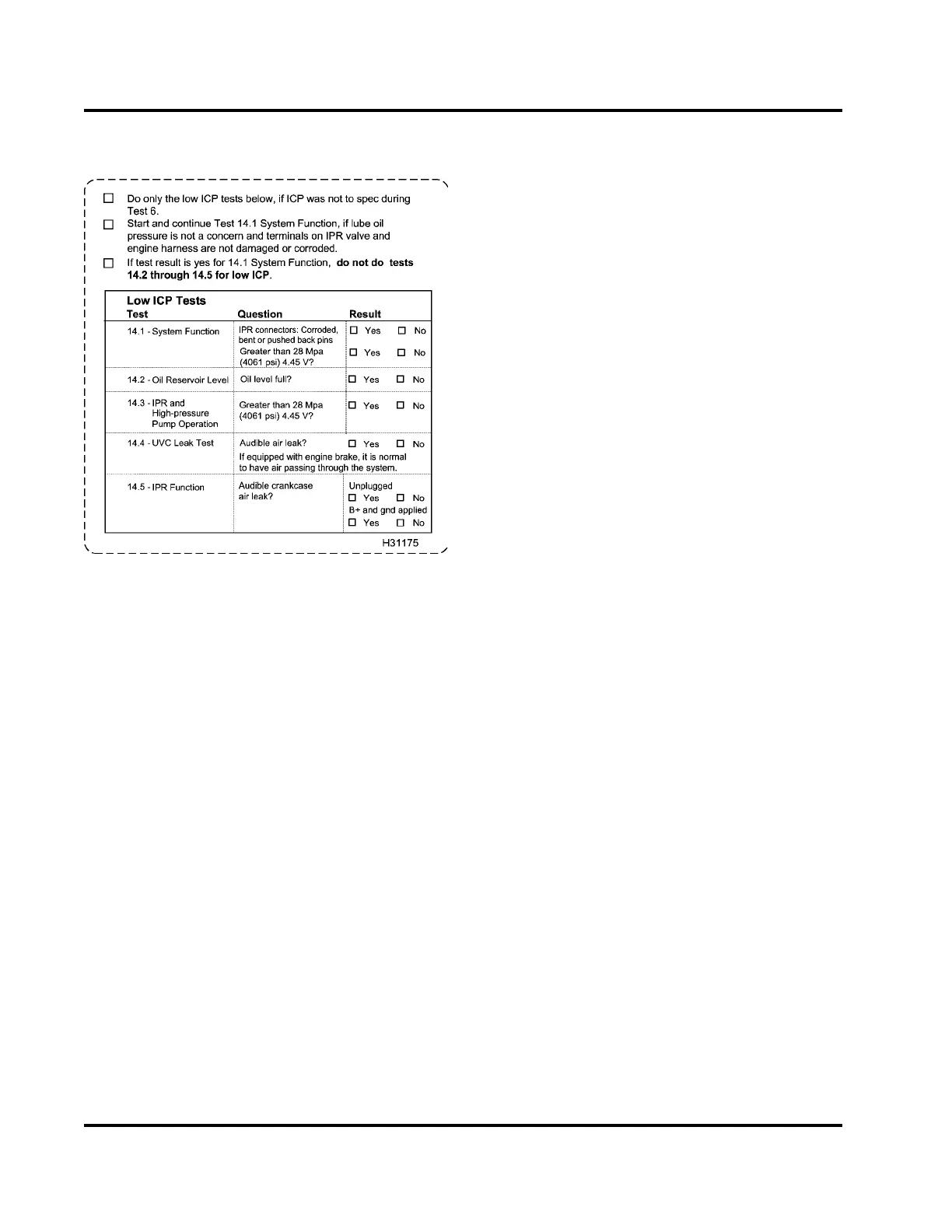

14. Low ICP System Pressure

Figure 222

Purpose

To determine the cause of low injection control

pressure that prevents engine starting

Tools

• EST with MasterDiagnostics® software

• EZ-Tech® interface cable

• Digital Multimeter (DMM)

• Actuator Breakout Harness

• Jumper harness (from Terminal Test Kit)

• Pressure Sensor Breakout Harness

• Socket or wrench (EOT sensor)

• Compressed air source 689 kPa (100 psi)

• Spare VT 365 ICP sensor (Part N o. -1845274C92

or equivalent)

• Spare high-pressure hose (Part No.-1842571C91

or equivalent)

NOTE: The mechanic is expected to keep the

spare ICP sensor and high-pressure hose for future

diagnostics. Expense the spare ICP sensor and

high-pressure hose as essent ial tools and keep it with

other dia gnostic too ls. Warranty will not cover the

cost of the spare ICP sens or and high-pressure hose.

Possible Caus es

• ICP system leakage

• Failed ICP sensor circu it

• Failed ICP sensor

• Failed IPR wiring (power and control)

• Failed IPR valve

• Low or no lube oil pressure

• Inoperative high-pressure oil pump

• Failed BCP sensor circuit

• Failed BCP sensor

• Inoperative brake shut-off valve of Diamond

Logic® engine brake

• BCP system leakage

• If ECM detects low boost pressure, an incorrect

feedback signal from A PS or the ICP sensor, the

ECM comma nd s the I P R v alve t o redu ce ICP.

14.1 – System Function

Start Test 14.1 System Function – continue Low ICP

System Pressure diagnostics, if no concerns are

found with the following:

• Lube oil pressure system has the ability to build

engine oil pressure while the engine is cranking.

• Inspect Injection Pressure regulator (IPR)

valve and engine wiring harness connector for

corrosion.

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any proced ures.

Follow all warnings, cautions, and notes.

©August 2008 Navistar, Inc.

Loading...

Loading...