236 6 PERFORMANCE DIAGNOSTICS

10. Injection Control Pressure

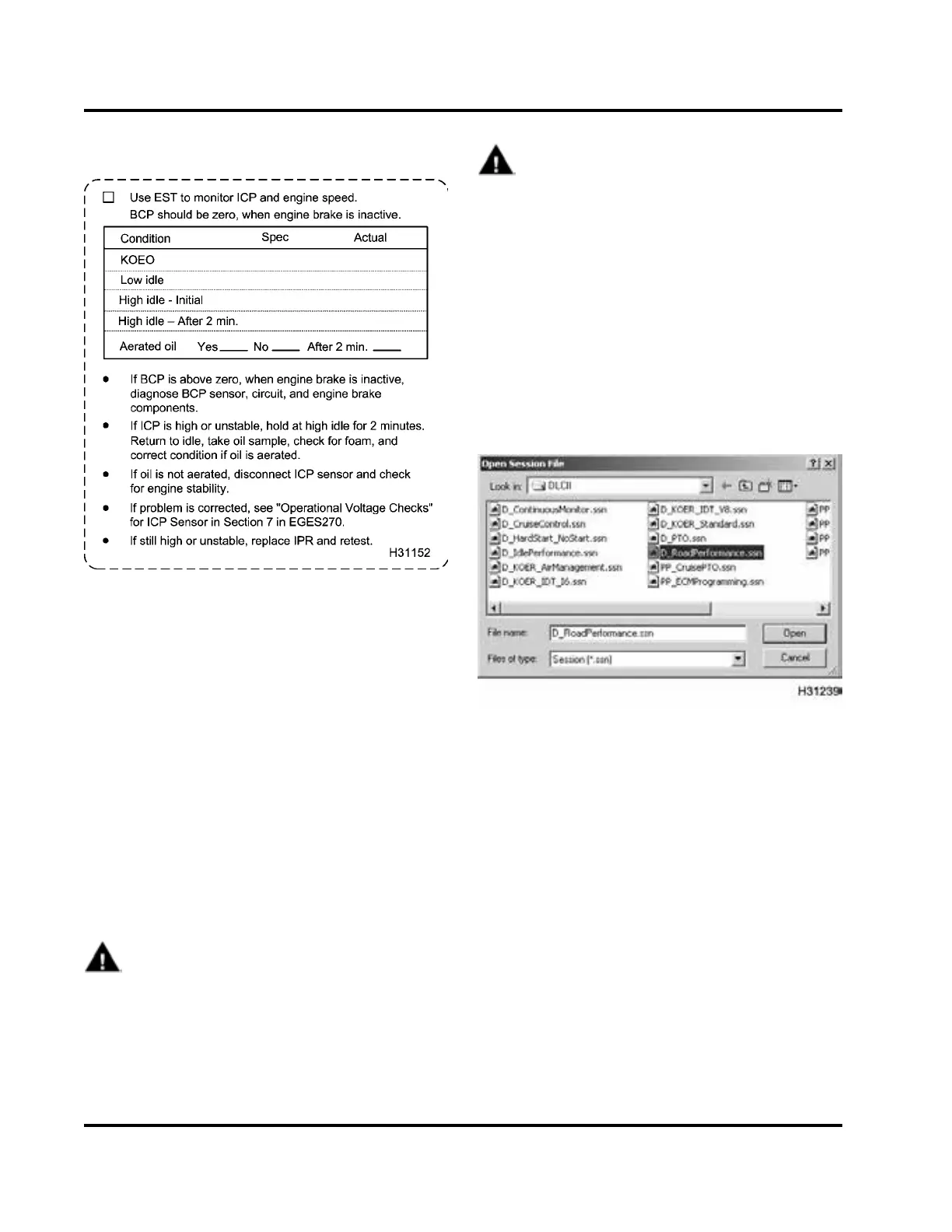

Figure 307

Purpose

To determine if the ICP system is providing enough

hydraulic pressure to operate the injectors

Tools

• EST with MasterDiagnostics® software

• EZ-Tech® interface cable

• ICP System Test Adapter

• Oil samp le line w ith inline shut-off valve

• Socket or wrench (EOT sensor)

Monitoring ICP and BCP using EST

WARNING: To avoid seriou s p

ersonal injury,

possible death or damage t

o the engine or

vehicle, read all safety i

nstructions in the “Safety

Information” section of

this manual.

WARNING: To avoid serious personal injury,

possible death or damage to the engine or vehicle

– comply with the following:

When running the engine in the service bay, make

sure the parking brake is set, the transmission is

in neutra l, and the wheels are blocked.

NOTE: If an EST is not available, use alternate test

procedures following this test.

1. See “DT 466 Performance Specifications” –

Appendix A (page 595) or “DT 570 and HT 570

Performance Specifications” – Appendix B (page

619) for specifications and record on Diagnostic

Form.

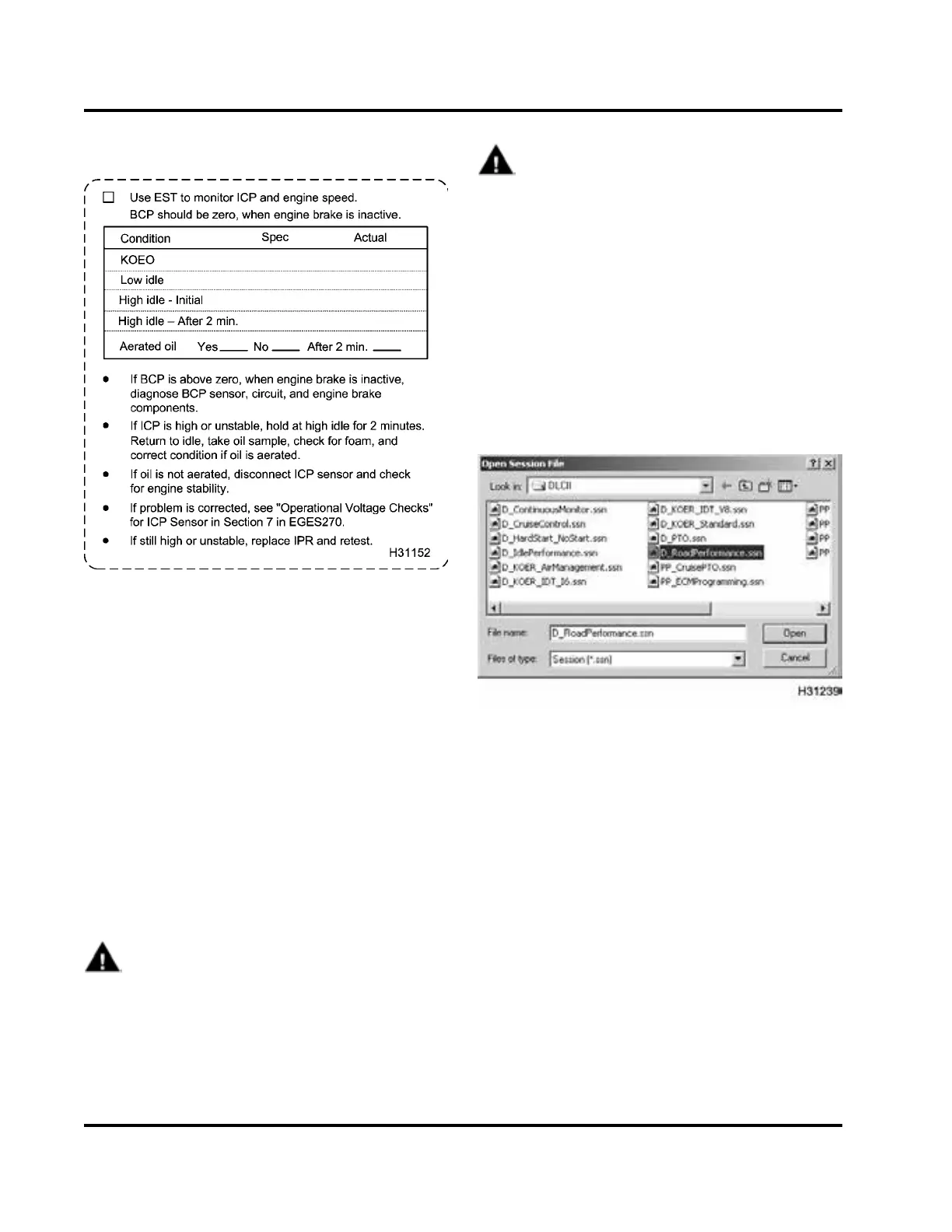

Figure 308 Road Performance.ssn

2. Open D_RoadPerformance.ssn to monitor engine

operation.

3. Turn the ignition switch to ON. Do not start engine.

Monitor KOEO Inject Ctrl Press (ICP). Record

results on Diagnostic Form.

• If injection control pressure is higher than

specification, the ICP sensor or circuitry may

be the cause.

This will cau se a lower than normal injectio n

control pressure command. See “ICP

Sensor” in Section 7.

• If injection control press ure is in KOEO

specification, continue to step 4.

4. Run engine at low idle, monitor ICP, and record

reading on Diagnostic Form.

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any proced ures.

Follow all warnings, cautions, and notes.

©August 2008 Navistar, Inc.

Loading...

Loading...