192 5 HARD START AND NO START DIAGNOSTICS

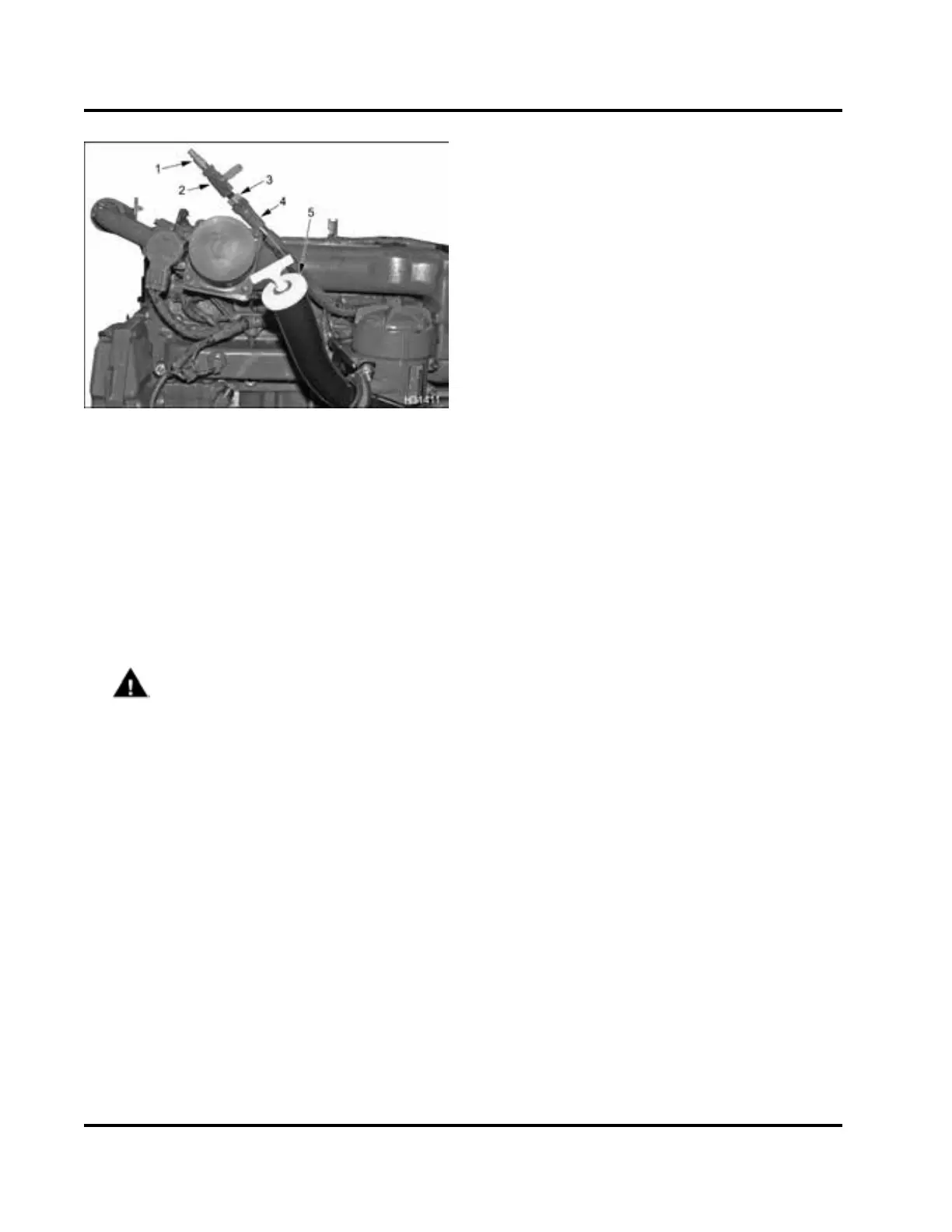

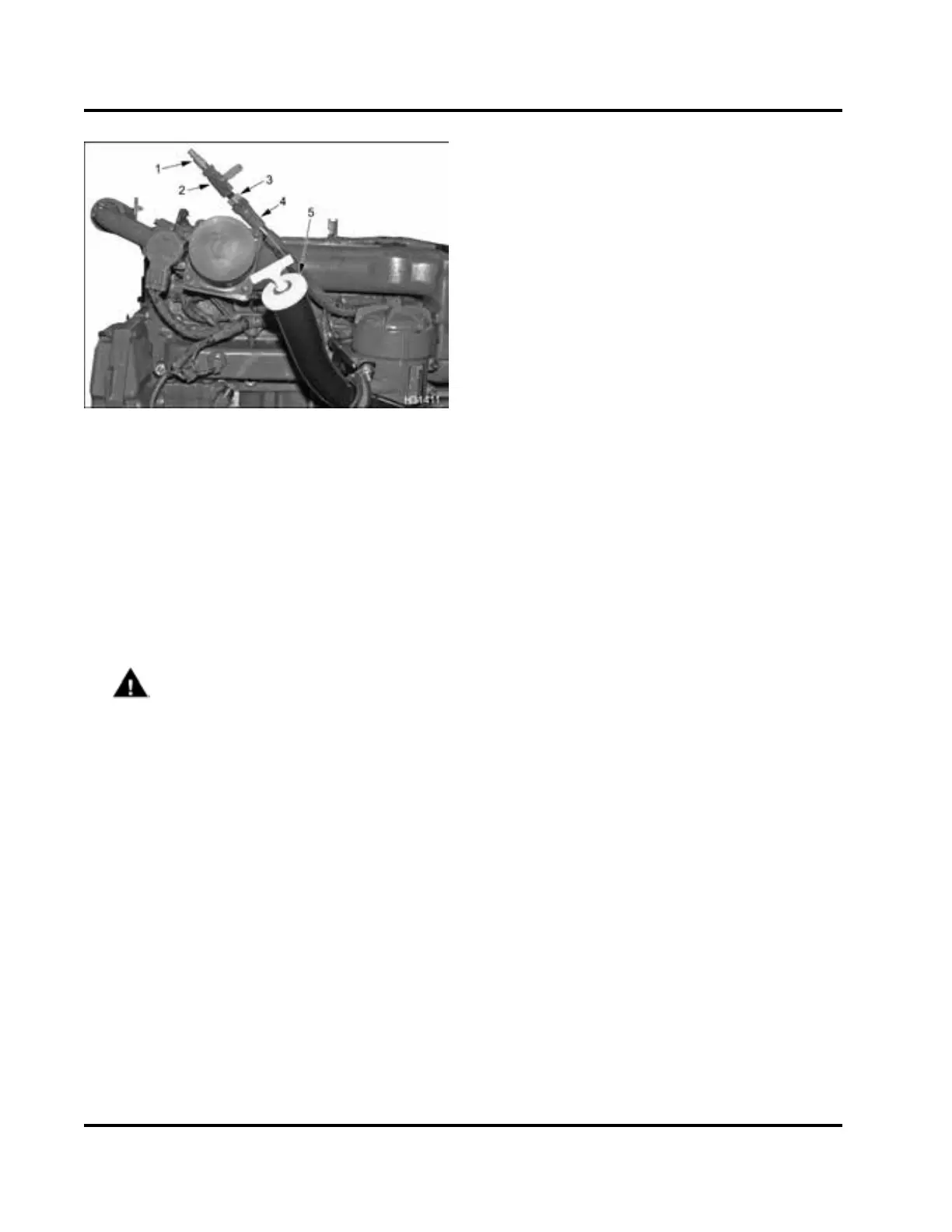

Figure 237 High-pressure oil hose with test

fittings installed

1. Air chuck

2. Shut-off valve

3. Fitting, 13/16-16 NPT

4. High-pressure hose

5. Oil level gauge

1. Install 13/16-16 NPT fitting, shut-off valve, and air

chuck fitting to high-pressure oil hose connected

to cylinder head.

WARNING: To avoid serious personal

injury, possible death, or damage to

the

engine or vehicle, do the following

:

• Install an inline shut-off valve.

If system does not leak when air is app

lied,

the system will maintain pressur

e.

When hose is removed, oil will be r

eleased

with air pressure.

• Use inlin e shut-off valve to cont

rol and

contain bleed-offpressure mix

ture (air and

oil).

2. Remove oil level gauge from oil fill tube.

3. Close shut-off valve.

4. Connect shop air supply line to test hose.

5. Apply 689 kPa (100 psi) of pre ssure. Slowly open

the shut-off valve.

6. Listen for an air leak in the crankcase through the

oil fill tube.

NOTE: Engines with engine brake option will have

a small amount of air passing through the system.

Air will pass through brake shut-off valve into the

brake oil gallery. The air will leak off through the

actuator pistons a nd the relief valve at the end of

the rail.

7. Record results on Diagnostic Form.

• If a leak is not heard, check previous test

results.

• If a leak is heard, check components under

the valve cover. Continue with step 8.

8. Close inline sh ut-off va lve to s to p air flow.

9. Remove the valve cover following procedures in

the Engine Service Manual.

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any proced ures.

Follow all warnings, cautions, and notes.

©August 2008 Navistar, Inc.

Loading...

Loading...