240 6 PERFORMANCE DIAGNOSTICS

6. Run engine at low idle, measure ICP signal

voltage, and record on Diagnostic Form.

• If ICP is high or unstable for low or high idle,

do step 8.

• If IC P is in spec ification, continue with Test 11

Injector Disable.

7. Run engine at high idle, monitor ICP, and record

initial results on Diagnostic Form. Continue to

run the engine at high idle for 2 minutes, monitor

ICP, and record the 2 minute results on Diagnostic

Form. Compare the two ICP readings. ICP that

rises above the specification at any point during

the two minutes, indicates oil aeration.

• If ICP is high or unstable for low or high idle,

do step 8.

• If IC P is in spec ification, continue with Test 11

Injector Disable.

WARNING: To avoid serious personal injury,

possible death or damage to the engine or ve

hicle

– comply with the following when taking oi

l

sample:

• When routing oil line, do not run the line t

oo

close to moving parts.

• Do not let the line touch hot engine surfac

es.

• Oil is hot. Use protective gloves when

taking

oil sample. Use caution handling oil s

ample to

avoid spilling.

WARNING: To avoid serious personal injury

or possible death, do not allow engine fluids to

stay on your skin. Clean your skin and nails

with soap and water, or a good hand cleaner.

Wash or properly throw away clothing or rags

containing engine fluids. Engine fluids contain

certain elements that may be unhealthy for skin

and could even cause cancer.

NOTE: Engine fluids, oil, fuel, and coolant, can be a

threat to the environment. Never dispose of engine

fluids by putting them in the trash, pouring them on the

ground, in the sewers, in streams or bodies of water.

Collect and dispose of engine fluids according to local

regulations.

8. Turn off engine.

9. Use the ICP system test adapter and inlin e

shut-off valve to make a test line assembly to

take oil sample.

NOTE: The mechanic is expected to keep the

test line for future diagnostics. Expense the test

line as an essential tool and keep it with other

diagnostic tools. Warranty will not cover the cost

of the test line.

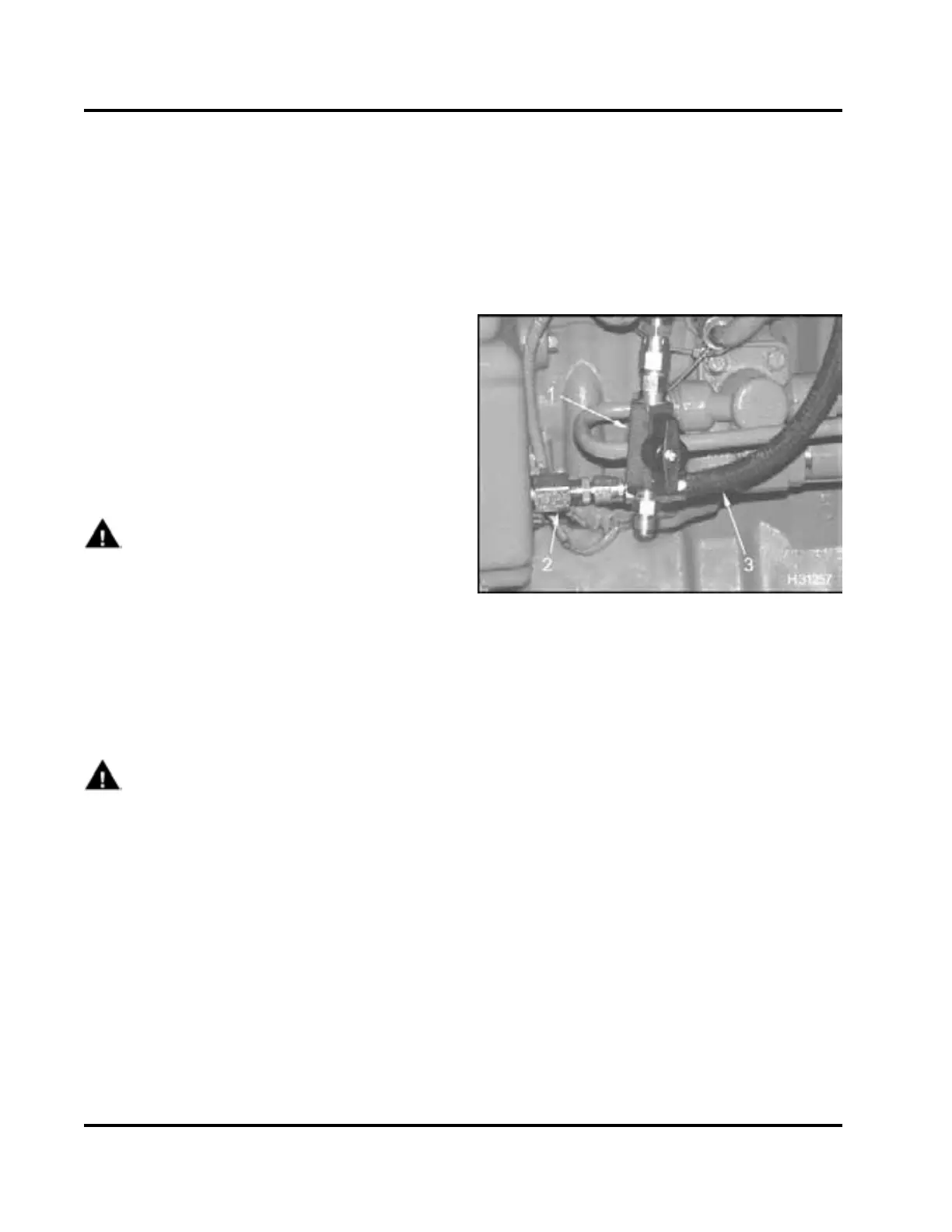

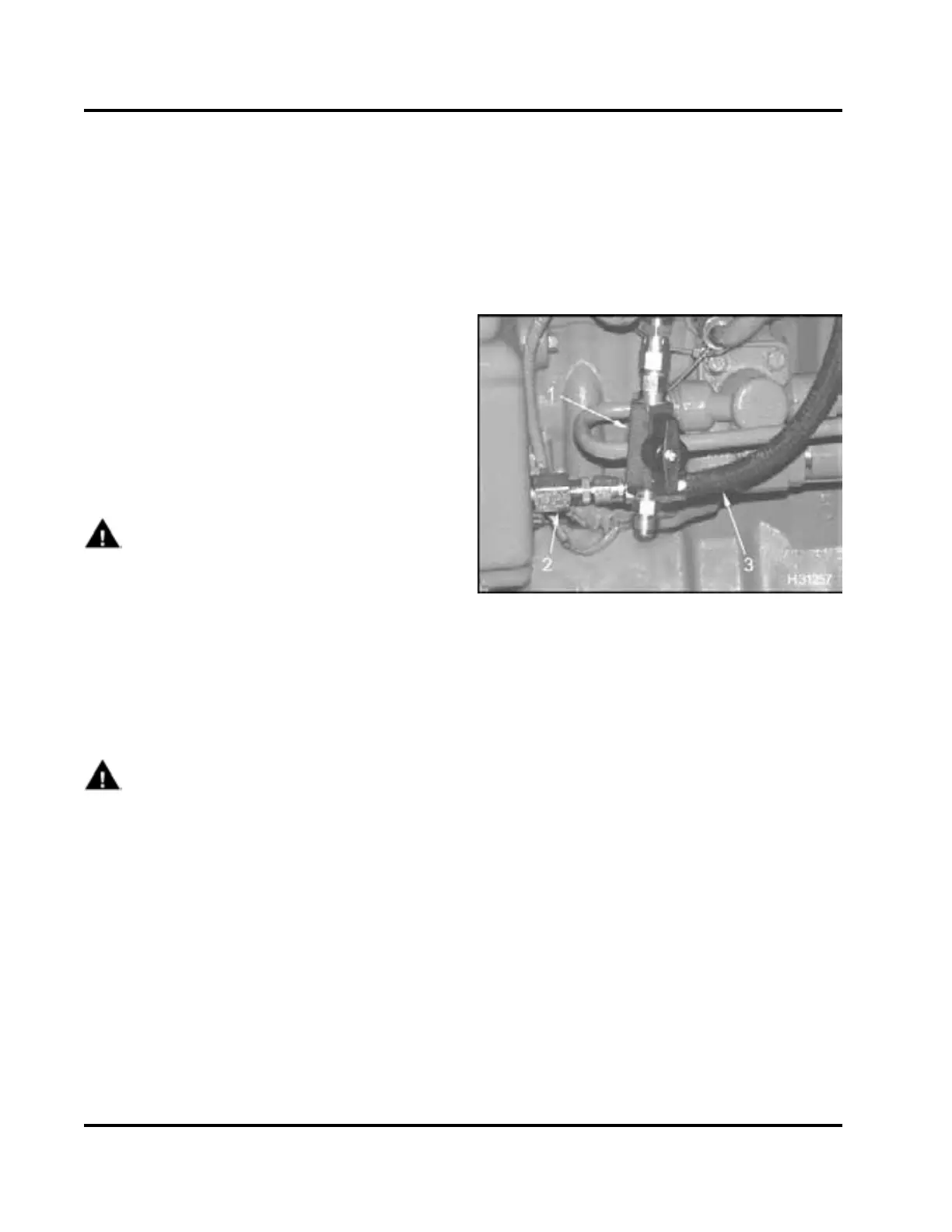

Figure 312 Test hose assembly

1. Inline shut-off valve

2. ICP system test adapter

3. Oil sample line

10. Remov e EOT sensor fro m EOT port. Oilwillspill

out. Quickly install test hose assembly and

capture oil sample in clear container.

11. Run engine at high idle for 2 minutes.

12. Return engine to low idle, take oil sample, and

check for aerated oil.

13. Record results on Diagnostic F orm.

• If oil is aerated, a large quantity of air bubbles

mixed throughout the oil, or foam build up on

top of the oil will be seen. Correct condition.

• If oil is not aerated, disconnect ICP sensor

and check engine stability. If proble m is

corrected, see “ICP Operational Volta g e

Checks” – Section 7 (page 457).

• If ICP is still high or unstable, and engine has

optionalengine brake, continue to “Monitoring

BCP u sin g VC G a ske t Break ou t H arness.”

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any proced ures.

Follow all warnings, cautions, and notes.

©August 2008 Navistar, Inc.

Loading...

Loading...