534 7 ELECTRONIC CONTROL SYSTEMS DIAGNOSTICS

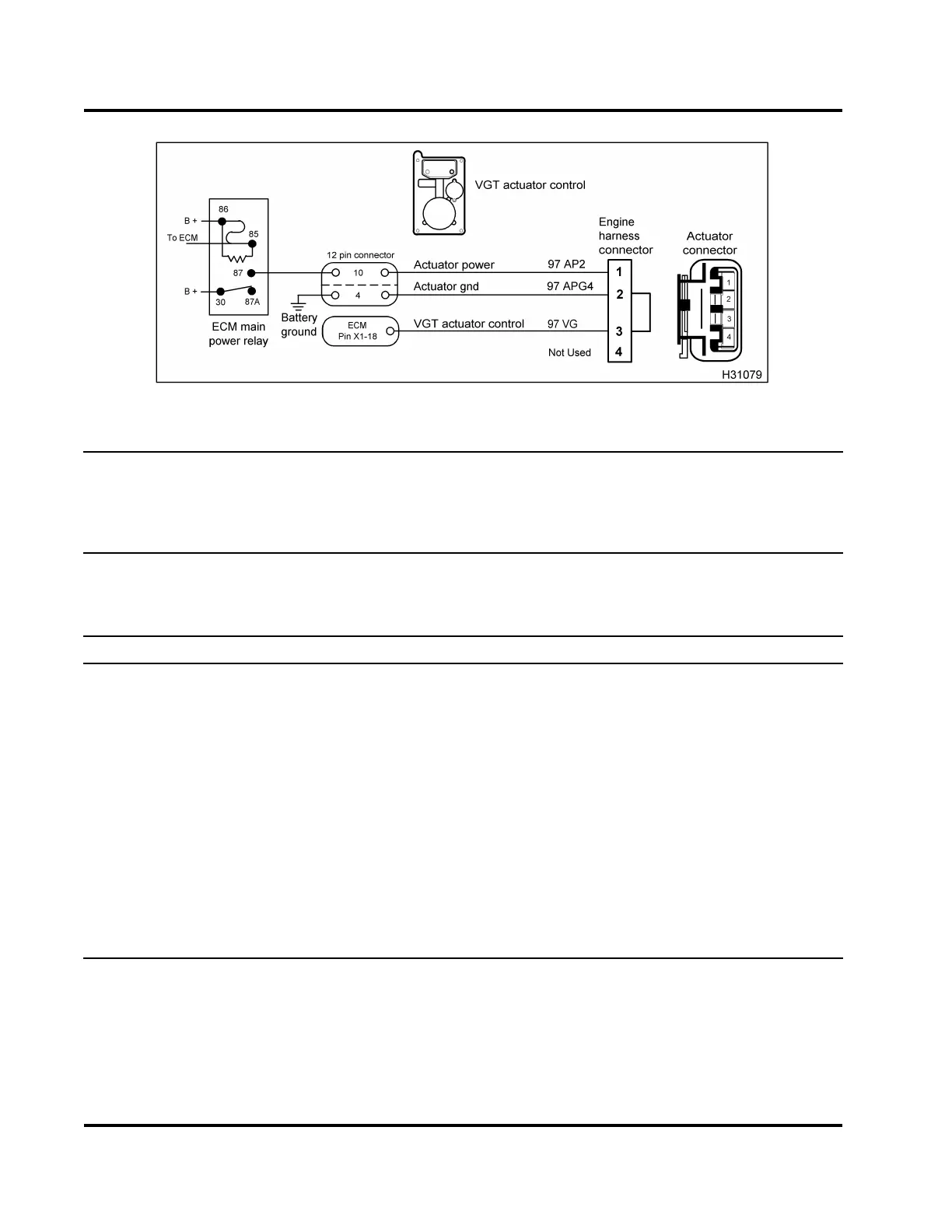

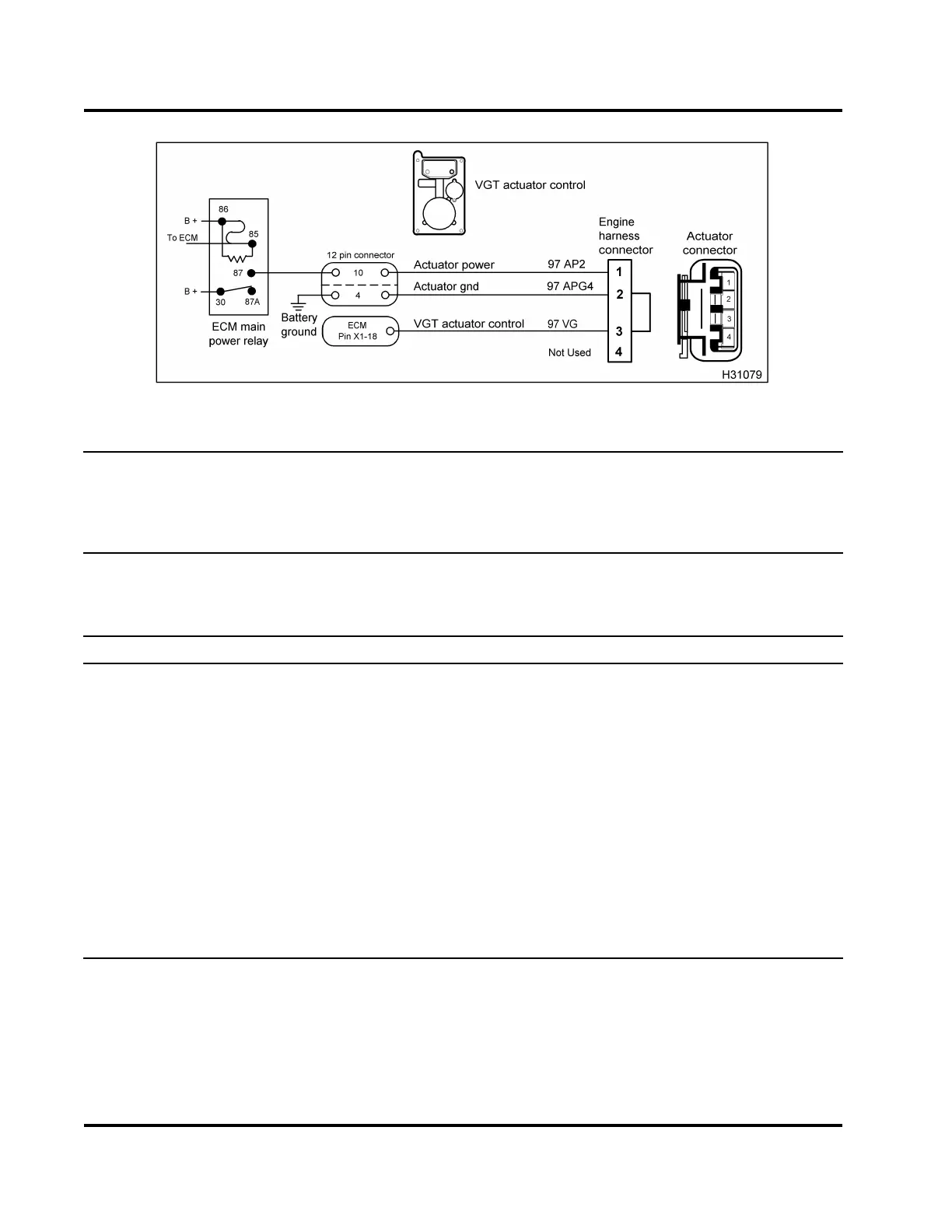

Figure 503 VGT circuit diagram

NOTE: I f an Actuator Co ntrol Voltage Check wa

s not to specification, continue w ith this check.

Turn the ignition switch to OFF when disconne

cting engine wiring harness connectors from components.

See truck Ch assis Electrical Circuit D iag ra

m M anual for circuit numbers, connector and fuse locations.

Actuator Control Voltage Check at E CM (Connect breakout box X-1 only to ECM and engine harness.

Engine harness is not connected to actuator harness. Connect 500 Ohm R esistor Harness between X1-18

and X1-6. Turn the ignition switch to ON. See “Diagnostic Software Operation” in Section 3 (page 68) for

procedure to do the Low and High Output State Tests.)

Test State/Point Setting/Spec Comment

KOEO DMM set to V - DC

X1–18 to X1– 6

DMM set to V - DC

1

DMM set to duty

cycle

2

If in specification, run the Low and High Output State

Tes ts .

If not in specification, disconnect engine harness from

breakout box harnes s and retes t.

• If not in specification, run the Low and High Output

State Tests.

•Ifinspecification, diagnose engine wiring harness.

Do Harness Resistance Check – VGT Actuator to

ECM (page 538).

Output State Test - Low DMM set to V - DC Listen and observe to verify if crank lever of VGT

actuator moves. Toggling between the Low and High

Output State Tests can be done during this test.

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© August 2008 Navistar, Inc.

Loading...

Loading...