DMTA-10022-01EN, Rev. C, January 2015

Software Options

75

In some cases, an error can occur if you are using a D790 transducer to measure

thicknesses above 18 mm (0.7 in.). Typically, this error is due to a mode-converted

shear-wave echo that may appear before the second back-wall echo. If this unwanted

echo is larger than the second back-wall echo, the gage measures the distance to it,

which produces a thinner reading.

You can usually distinguish the unwanted shear-wave echo from the correct back-wall

echo by examining the waveform display. The distance between the first and the

second back-wall echoes is the same as the distance between the zero thickness point

and the first back-wall echo. If there is an echo between the first two back-wall echoes,

it is probably a mode-converted shear-wave echo. Use the manual echo-to-echo

detection mode techniques, and manually adjust the E1 blank to eliminate this error

(see “Blanking Adjustments in Manual Echo-to-Echo Detection Mode” on page 73).

Using the D797 transducer beyond 18 mm (0.7 in.) helps eliminate the possibility of

this error.

In some cases, the second or third back-wall echo is smaller in amplitude than

subsequent echoes, which causes the instrument to give a double or triple reading. If

you are using a D790 transducer, this effect may occur around 5 mm (0.2 in.) on flat,

smooth steel samples. If this occurs, it is clearly visible on the waveform display, and

you can work around it using the manual Echo-to-Echo detection mode, or by moving

the extended blank beyond the previously detected first echo.

When the 45MG cannot make an echo-to-echo reading, the LOS flag appears on the

screen. In this case, the waveform display shows that either no echoes are large

enough to be detected, or that only one echo is detectable. In the latter case, the Echo-

to-Echo detection bar begins at the detected echo, but extends indefinitely to the right.

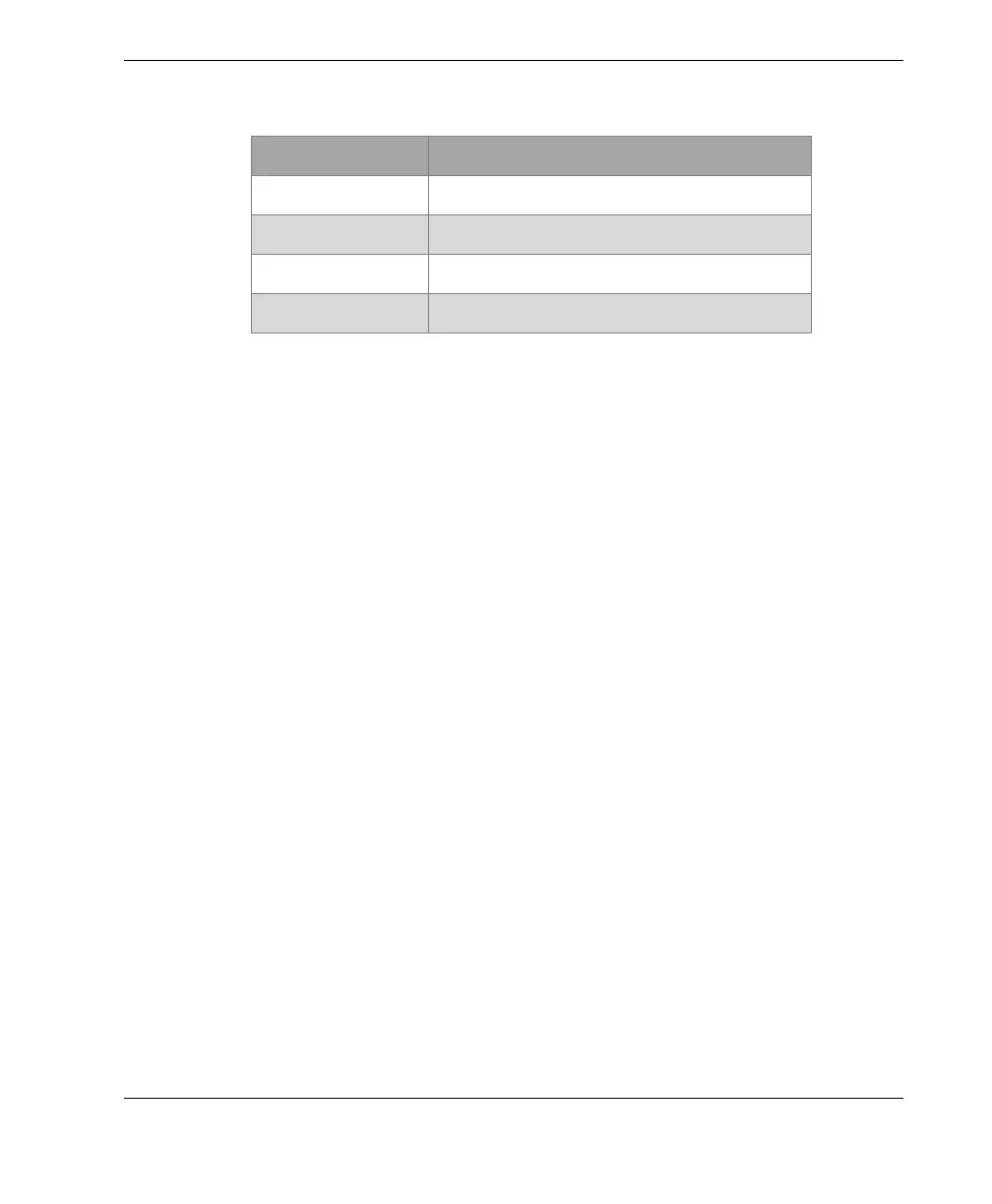

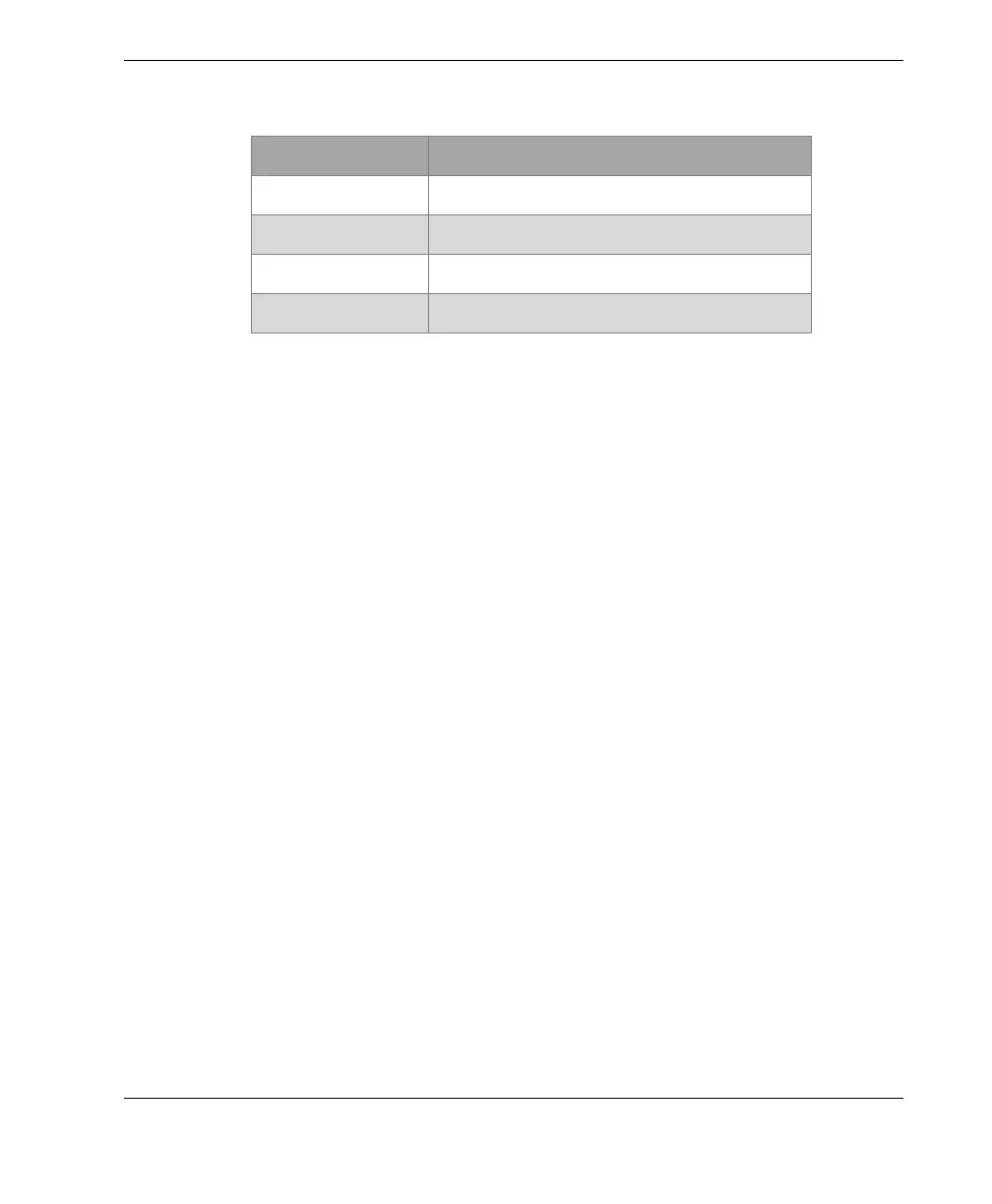

Table 4 Recommended transducers for various steel thickness ranges

Transducer type

Thickness range

a

a. Thickness ranges are dependent on the transducer type, material

conditions, and temperature.

D798 1.5 mm to 7.6 mm (0.060 in. to 0.300 in.)

D790/791 2.5 mm to 51 mm (0.100 in. to 2.00 in.)

D797 12.7 mm to 127 mm (0.500 in. to 5.00 in.)

D7906 2.5 mm to 51 mm (0.100 in. to 2.00 in.)

Loading...

Loading...