Using CX-Supervisor with OPC Servers SECTION 17 Using CX-Supervisor as an OPC

247

17-1-3-5 Who should care about OPC?

You should care about OPC if your applications are largely run in personal

computers and you are involved with solving plant integration problems. As a

critical mass of servers and OPC-enabled applications become available,

OPC is likely to become an important part of your plant integration tool set.

The OPC specification promises a future without proprietary interfaces that will

greatly benefit both manufacturing customers and automation suppliers.

17-1-3-6 How is OPC going to improve my bottom line?

From a business perspective, the use of OPC for connectivity promises to

reduce the cost of automation, control, and integration solutions. By using

OPC compliant products, significant savings can be achieved through shorter

development efforts and a wide choice of vendor hardware and software

solutions. For every automation system installed today, a significant amount of

time and money is spent ensuring that the system can share information with

other systems and devices. OPC will save the customer time and money by

eliminating a lot of the system integration problems caused by lack of open

standards that exist between automation devices, systems, and manufacturing

software. After an automation system is installed, OPC will not improve

business bottom line directly; however, OPC will provide a common method to

access real-time information. The real key to improving the bottom line is to

distribute and use the information throughout the business' value chain.

17-2 Using CX-Supervisor with OPC Servers

The exact procedure for connecting CX-Supervisor to Third Party OPC

Servers will depend on the server being used. Consult your server

documentation for full details. However, the following is a basic overview:

1, 2, 3… Start the OPC Server and configure any settings and workspace items as

described in the vendor's manual.

1. Start CX-Supervisor and open your application.

2. Open the Point Editor by selecting the Point Editor option from the

Utilities menu or by clicking the button.

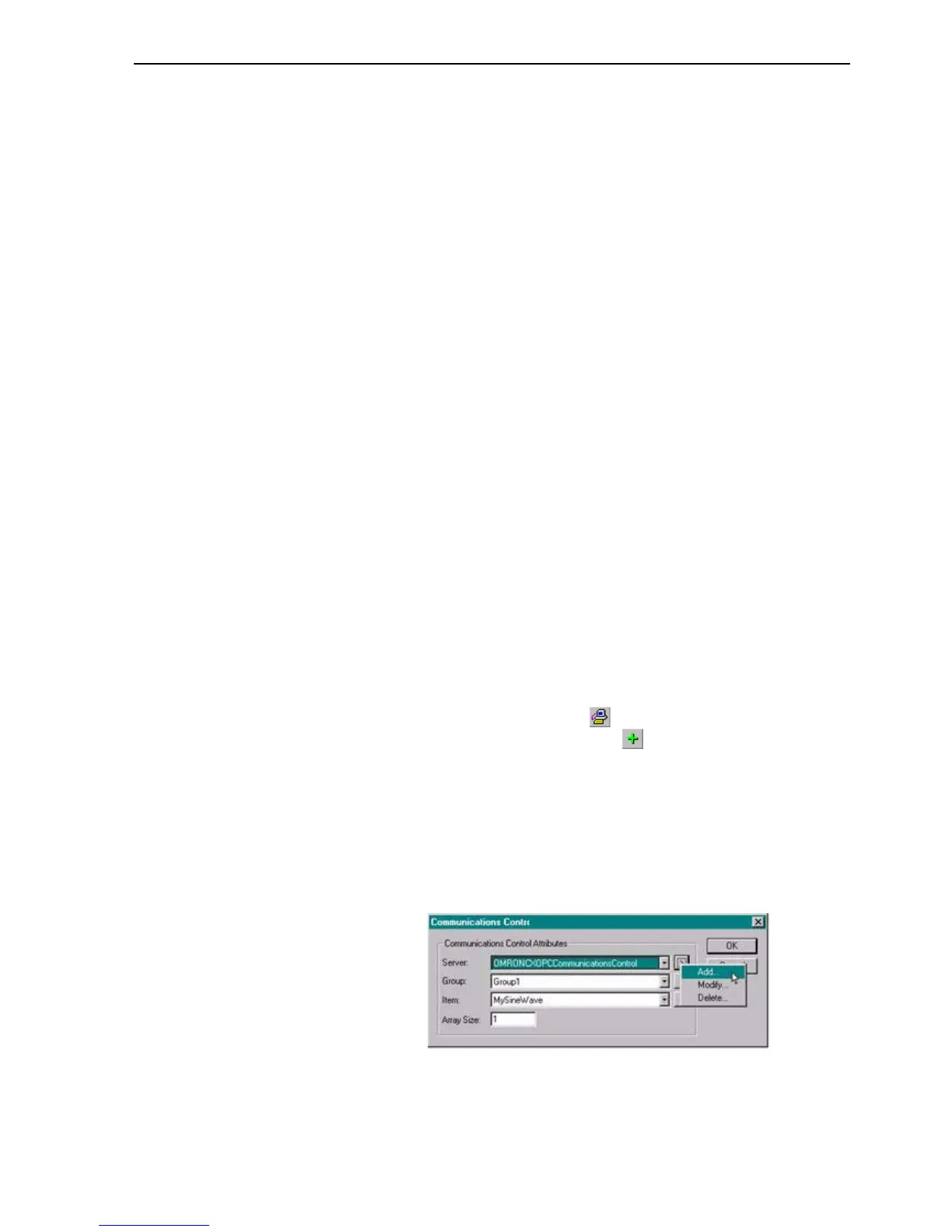

3. In the Point Editor dialog box click the button in the toolbar to open the

Add Point dialog box.

4. In the Add Point dialog box move to the I/O Type: options and select the

Input, Output or Input / Output option as appropriate. Note that the I/O

Update Rate: and I/O Attributes: options and displayed.

5. In the I/O Attributes: options select OPC/Other and click the Setup button.

This will open the Communications Control Attributes dialog box.

6. In the Communications Control Attributes dialog box enter the appropriate

parameters as follows:

Communications Control Attributes

Loading...

Loading...