6

05.01

6-164

Siemens AG 2001 All rights reserved

SIMODRIVE 611 Planning Guide (PJU) – 05.01 Edition

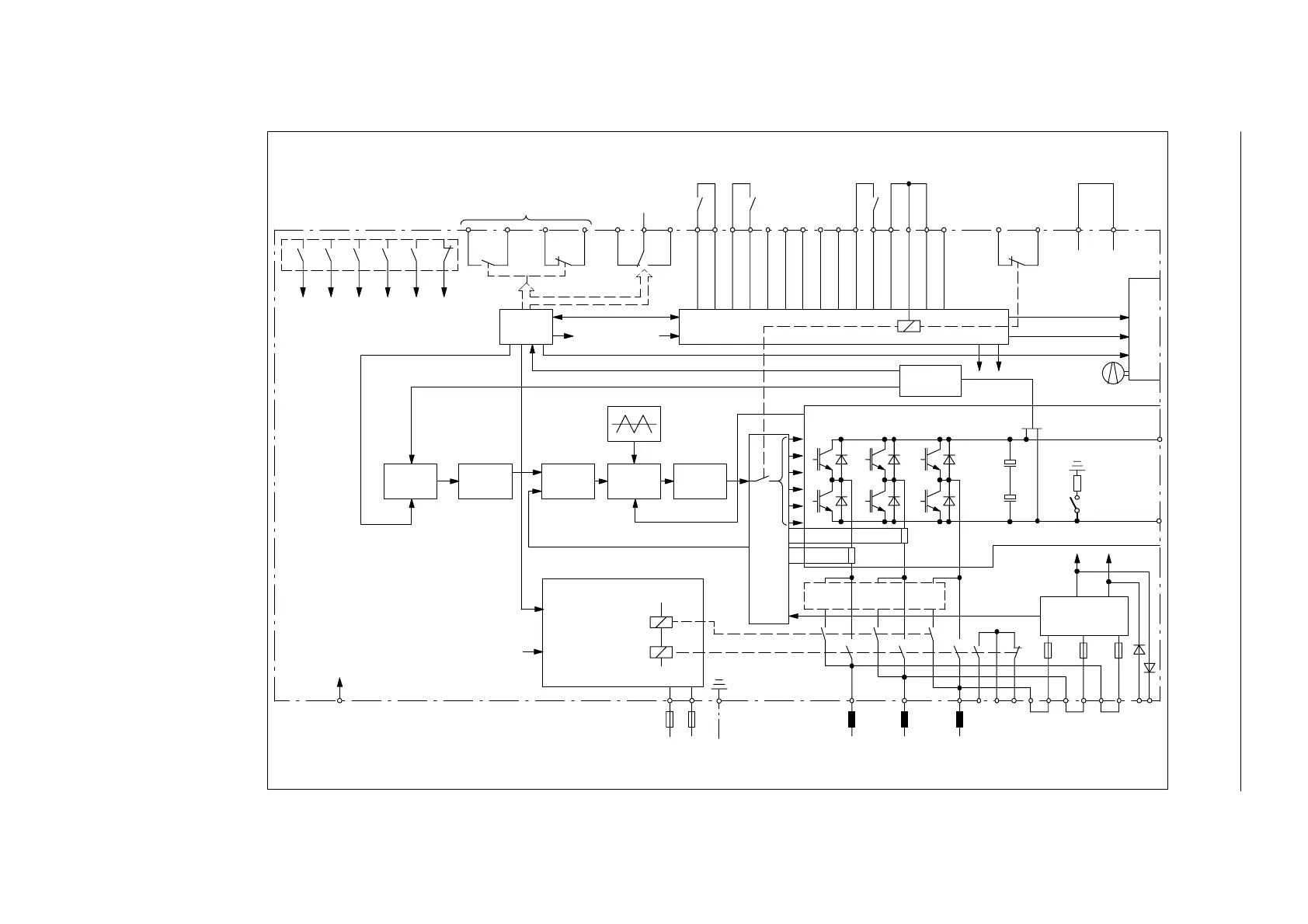

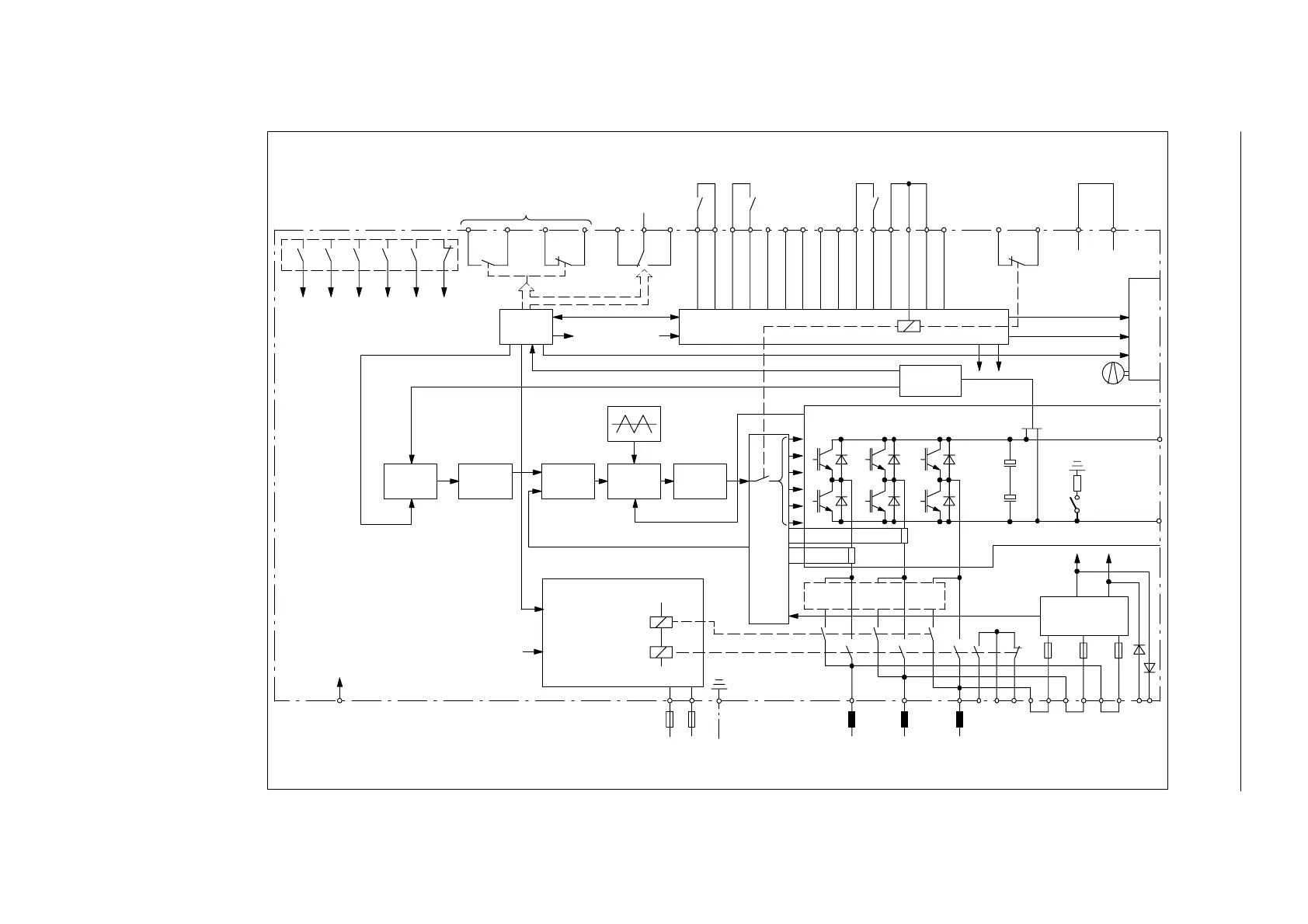

DIL switch

Signal,

ready/

fault

I

2

t pre–alarm

and motor

overtemperature

Drive

enable

Pulse

enable

Reset Term. 112

setting–

up

3)

Term.

48

start

Checkback signal,

start inhibit

Equipment

bus

X151

Monit

oring

Voltage

controller

Current

setpoint

limiting

Current

controller

Pulse

generation

Gating

NS 1 X131

Electronics power supply

NS 1 NS 2

NS 1 NS 2

AS1 AS2112 48 19

FR–

9R15151044457

MN24N15P15P24

639964

FR+

Safety relay, start inhibit

Power supply and

signals

Equipment enable

V

act

5.372 73.1 73.2 74 5.25.1

DC link

sensing

V

mot

= 600V/625V

6

2)

1

1)

S1

2

1)

3

1)

4

1)

5

1)

Control

unit

I

act

T

max.

power

module

P600

M600

Line supply

rectification and

synchronization

DC link pre–

charging

circuit

Signal,

line contactor

Commutating

reactor

1) Status when supplied, OFF

2) Status when supplied, ON

3) Jumpers closed when supplied

Term. 1U1–2U1, 1V1–2V1, 1W1–2W1

Term. 9–112–48

Term. NS1–NS2

M500P500

4)

1W1 2W1 1V1 2V1 1U1 2U1U1 V1 1 W

L1 L2 L3

Line supply 3–ph. 400 V

AC (415/480V)

113 111 213

X131

PE

PE1L2

L2

L1

L1

Line supply 2–ph. 400V AC

(415/480V)

F1, F2

NS 2

Pre–charging

contactor

Line contactor

3)

3)

Setting, refer to

Section 6

5)

6)

4) Jumper

open when supplied

5) Terminals L1, L2 only for I/R modules

80 and 120 KW

6) Term. 113 not available for

5 and 10 KW UI modules

AB

100 k

AB

DC link controller

Fig. 6-3 Block diagram, line supply infeed module (I/R)

6 Infeed Modules

Loading...

Loading...