2 System Configuration

2

05.01

2.8 Line supply connection

2-51

Siemens AG 2001 All rights reserved

SIMODRIVE 611 Planning Guide (PJU) – 05.01 Edition

This means, that within the clocked transistor drive converter, the voltage stres-

sing of the insulation distances between the power circuits referred to the line

supply potential and the open–loop and closed–loop control circuits, referred to

the neutral conductor is maintained according to a rated voltage of 300 V in

compliance with DIN EN 50178.

Upstream protective devices to protect against hazardous currents flowing

through the human body or for fire protection (e.g. fault current protective

devices) must be universal devices in compliance with DIN EN 50178. If other

fault current protective devices are used, a transformer with separate windings

must be connected upstream from the drive converter to de–couple it from the

line supply.

DC current components may be present in fault currents which occur due to the

6–pulse three–phase bridge circuit in the line supply infeed module. This should

be taken into account when selecting/dimensioning a fault current protective

device.

The SIMODRIVE unit may be directly connected to TN line supplies with a

universal current–sensitive residual–current protective device with selective

cut–out characteristics as protective measure.

Note

Only I/R modules, 16 kW and 36 kW, may be directly connected to a line

supply with residual–current protective devices.

Delayed universal current–sensitive residual–current protective device with

selective cut–out characteristics can be used without any restrictions to provide

protection against hazardous currents flowing through the human body.

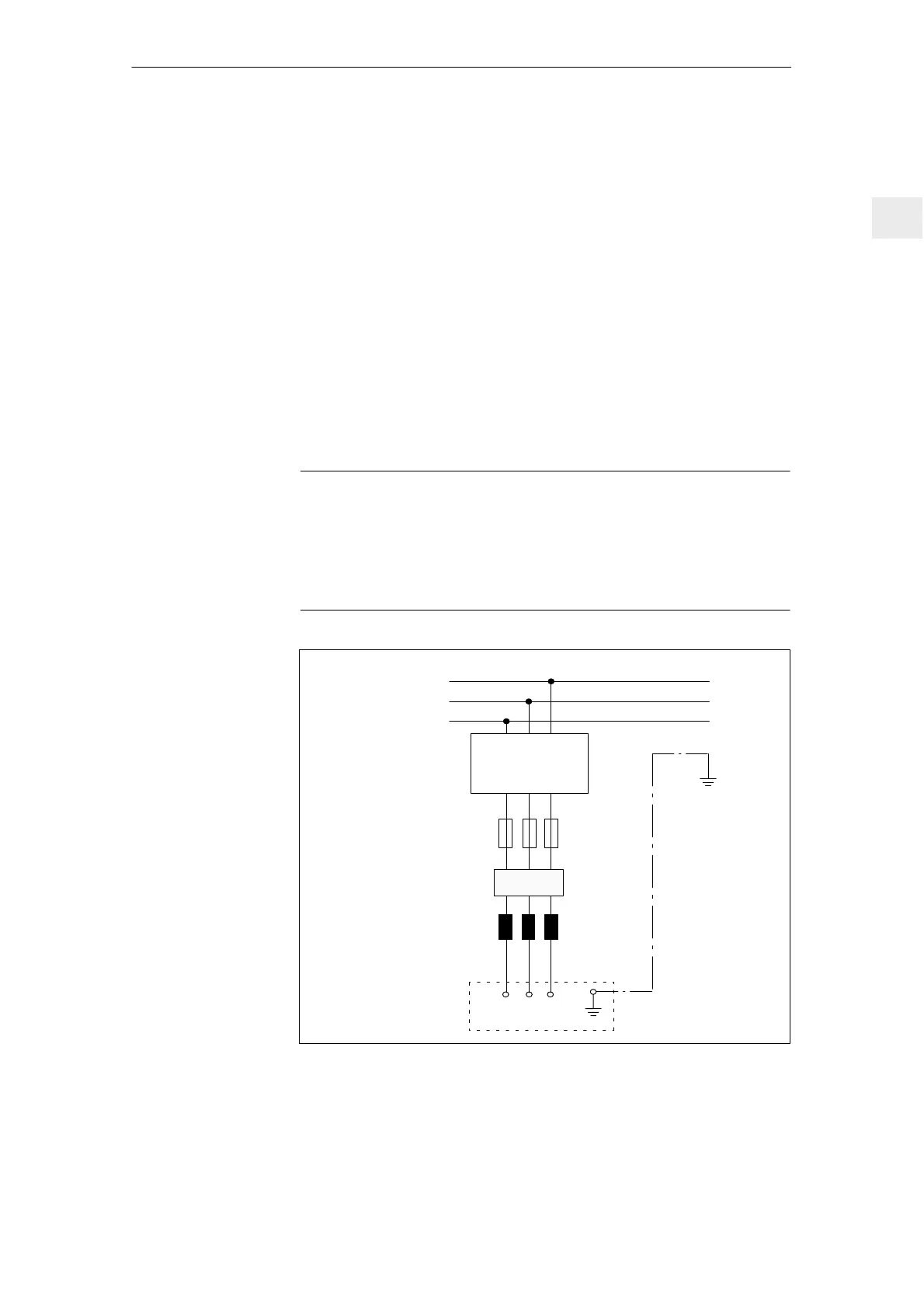

Commutating reactor

U1 V1 1 W

Connection diagram with residual–current protective device

PE

L3

L2

L1

NE module

residual–current

protective device

Universal current–

sensitive

Z

Fig. 2-12 Connection diagram, residual–current protective device

Direct connection

to line supplies

with residual–

current protective

device

Loading...

Loading...