Procedure

If there are deviations from normal operation or if faults occur, proceed as follows.

1. Identify the fault using the following table.

You should also take account of the messages of the converter.

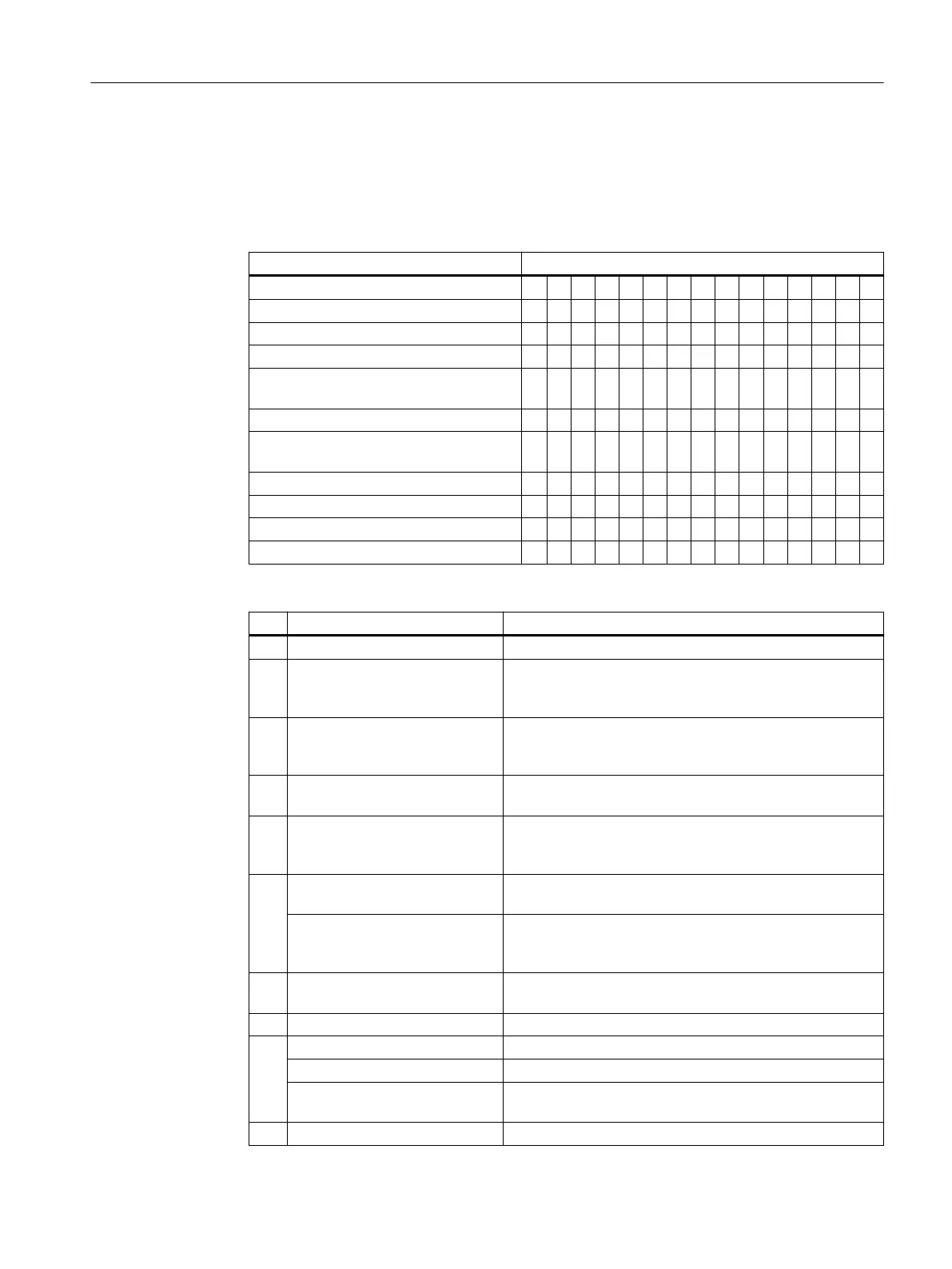

Fault Fault cause

Motor does not start A B

Motor starts slowly A C F

Humming sound when starting C F

Humming sound in operation A C F

High temperature rise under no-load op‐

er

ation

D I

High temperature rise under load A C I

High temperature rise of individual wind‐

ing sections

F

Uneven running J K

Grinding sound, running noise L

Radial vibrations M N O P R

Axial vibrations O Q R

2. Rectify the fault using the following table.

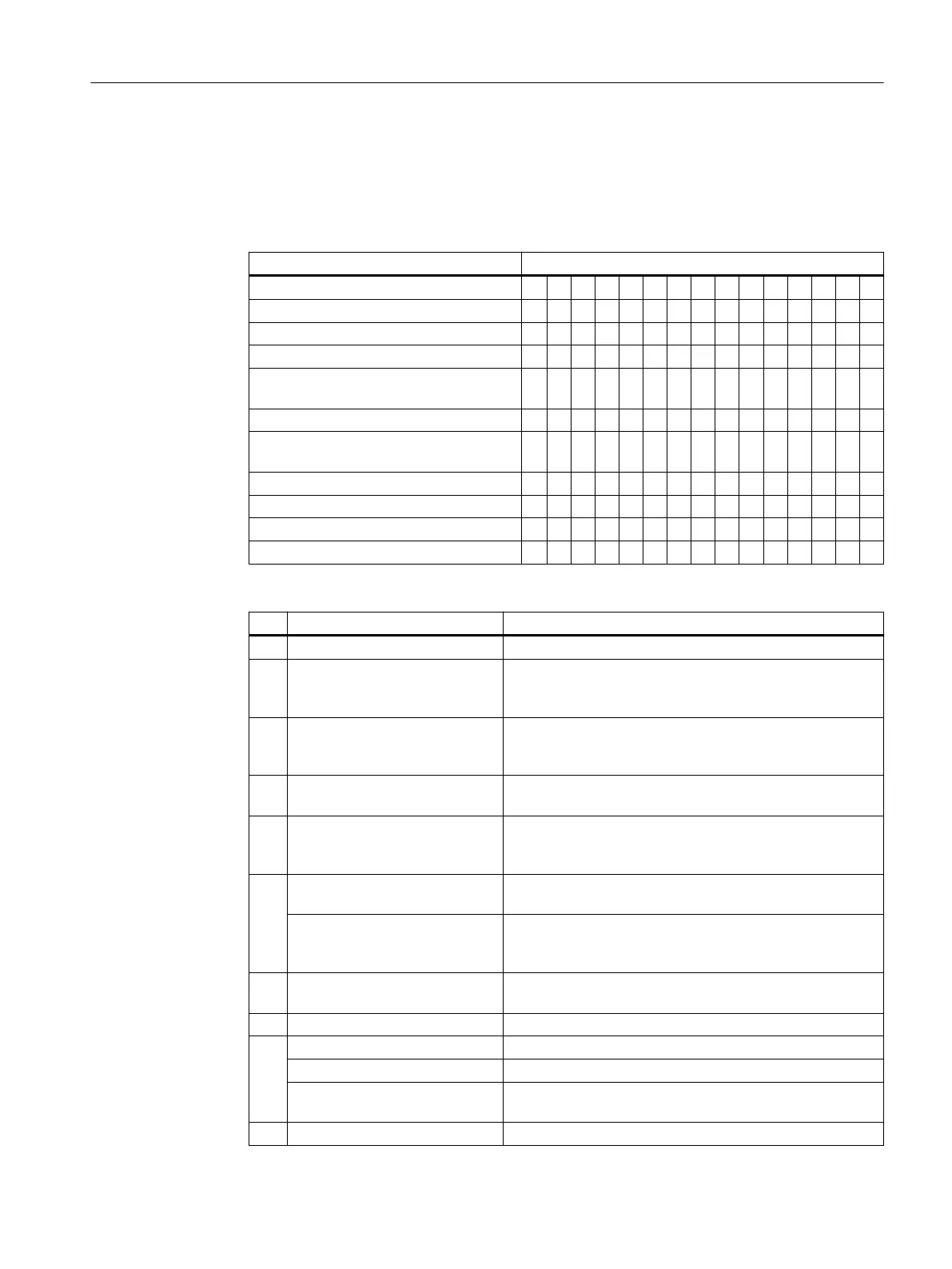

No. Fault cause Remedial measures

A Overload Reduce load

B Interrupted phase in the convert‐

er line supply cable or mot

or

winding

Check the converter and converter line supply cable, meas‐

ure the winding resistance and insulation resistance, repair

after consultation with manufacturer

C Interrupted phase in the convert‐

er line supply

cable aft

er switching on

Check the converter, converter line supply cable, and the

winding resistance

D Converter output voltage too

high, frequency t

oo low

Check the settings on the converter, perform automatic

motor identication

F Winding short-circuit or phase

short-circuit in s

tator winding

Measure the winding resistances and insulation resistan‐

ces, repair after consultation with the manufacturer, re‐

place the motor if required

I Heat dissipation impeded by de‐

posits

Clean the surface of the servo drive system and ensure that

the cooling air can o

w in and out unimpeded

Cooling air inlet or outlet is

blocked b

y foreign bodies

Remove the things that block the inlet or outlet and ensure

that the cooling

air can ow in and out unimpeded

J Insucient shielding for mot

or

and/or encoder cable

Check the shielding and grounding

K Excessive drive controller gain Adjust the controller

L Rotating parts are grinding Determine cause and adjust parts

Foreign bodies inside the motor Replace the motor

Bearing damage For low or medium inertia motors, replace the motor; for

high iner

tia mot

ors, replace the bearings

M Rotor not balanced Replace the motor

Corrective maintenance

13.2Service and maintenance for the motor

SINAMICS S200 PROFINET servo drive system with SIMOTICS S-1FL2

Operating Instructions, 11/2023, FW V6.3, A5E51646752B AB 601

Loading...

Loading...