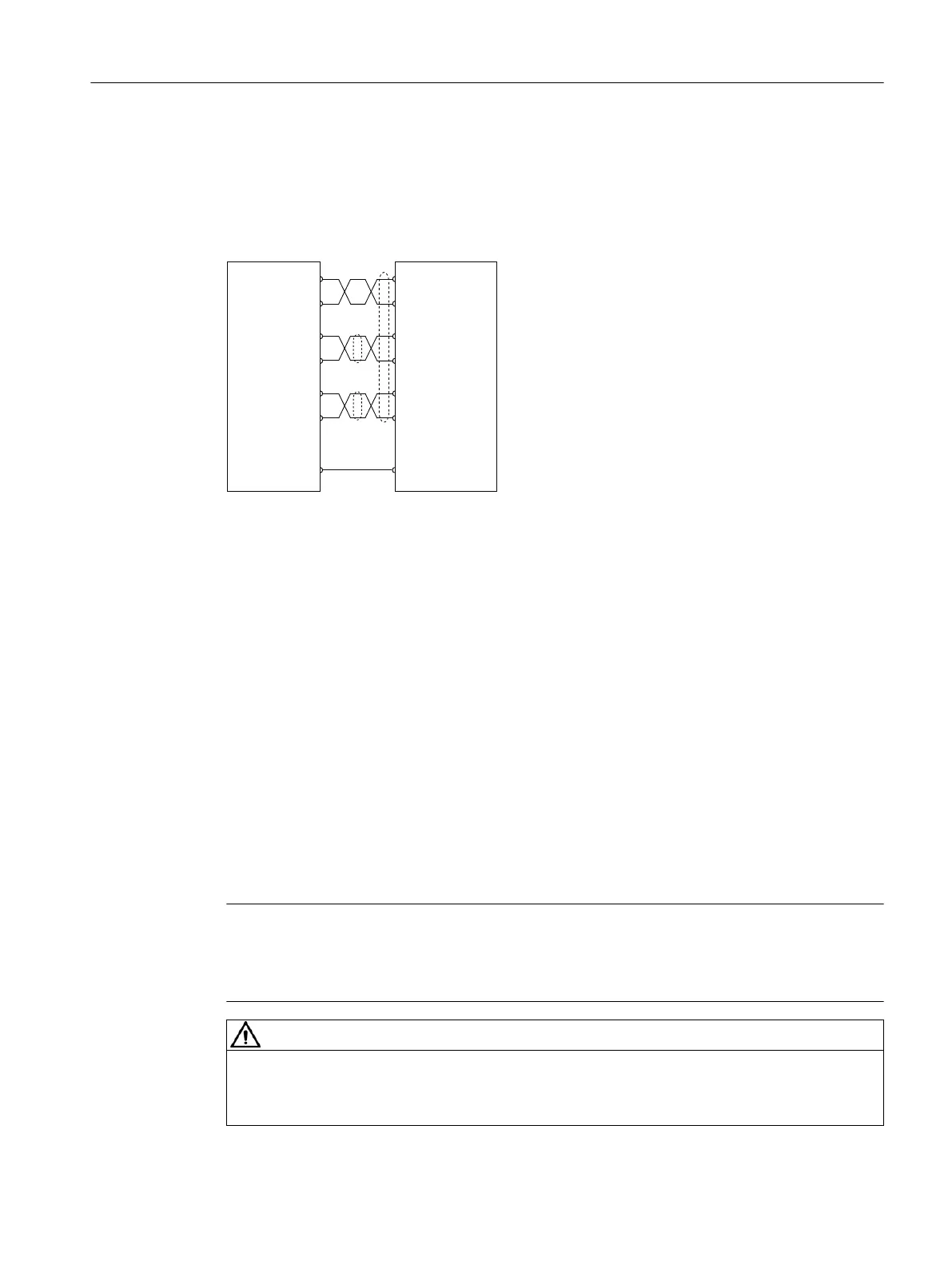

6.5.4.3 Wiring

Connection example

<HOORZ

*UHHQ

%URZQ

%OXH

5HG

:KLWH

&RQYHUWHUVLGH

0RWRUVLGH

*URXQGLQJ

6KLHOGLQJ

&ORFNB3

&ORFNB1

'DWDB3

'DWDB1

39

0

0

3B6XSSO\

&ORFNB3

&ORFNB1

'DWDB3

'DWDB1

Figure6-10 Encoder connection

More information

F

or more inf

ormation about cable requirements, see Section "Cables and connectors

(Page130)".

For more information about assembling cable terminals, see Section "Assembling cables

(Page879)".

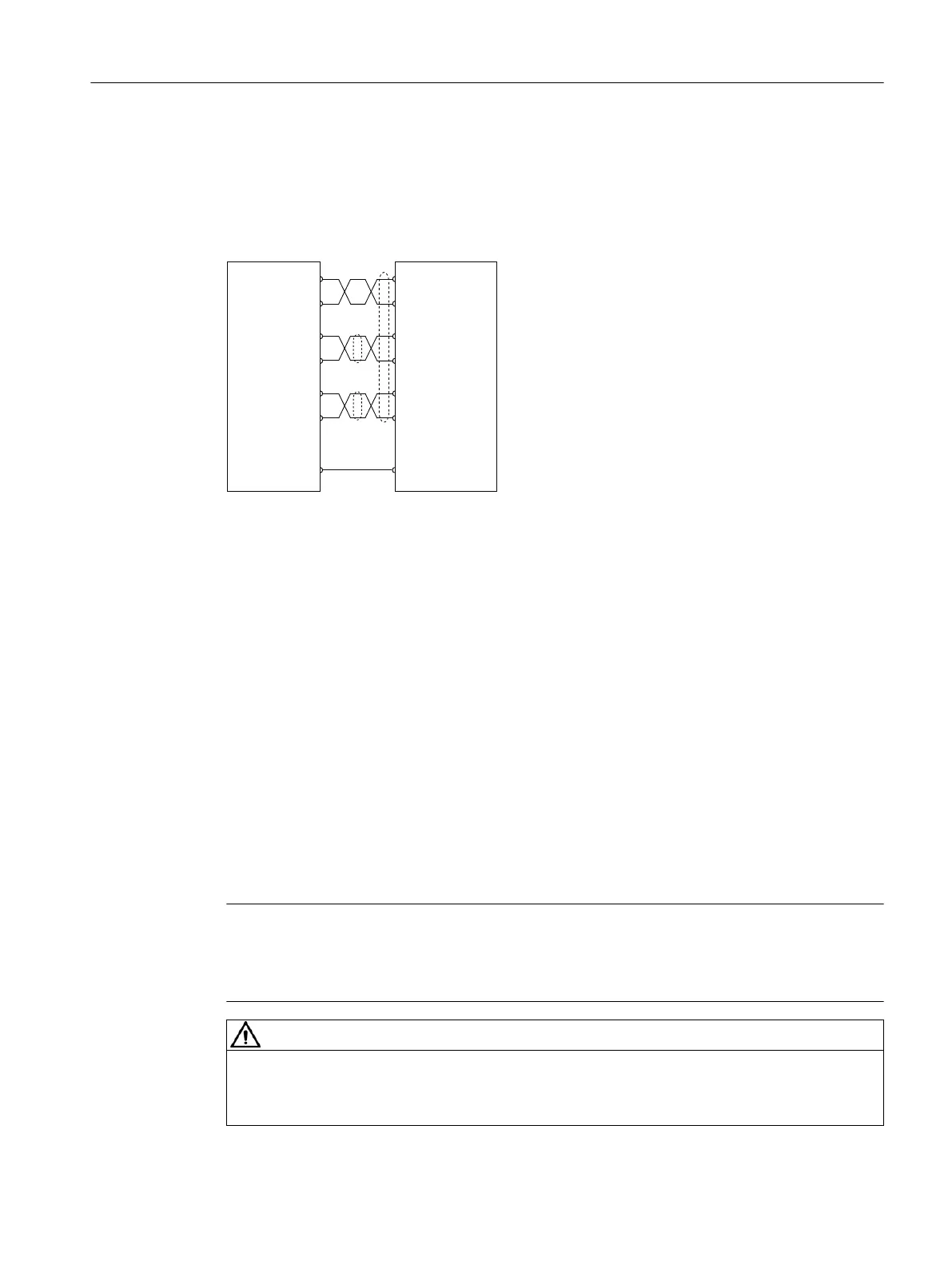

6.5.5 Rotating the connectors at the motor

Overview

The connectors at the 1FL2 motor with shaft heights 45, 48, 52, 65, and 90 can be rotated to a

dierent angle to a limited extent.

Use a suitable socket connector as a lever to rotate the connector.

Note

Rot

ating the connectors

• Do not exceed the permissible range of rotation.

• To ensure the degree of protection, do not rotate more than 10 times.

WARNING

Adjusting cable directions

Bef

or

e adjus

ting the cables, switch o the power supply. Otherwise, the motor contains a

hazardous voltage and a risk of electric shock.

Connecting

6.5Connecting the motor

SINAMICS S200 PROFINET servo drive system with SIMOTICS S-1FL2

Operating Instructions, 11/2023, FW V6.3, A5E51646752B AB 145

Loading...

Loading...