Communication

7.3

CHECKING THE TIME CYCLE

There are 2 ways, in case the controller has a time cycle greater than what was adjusted.

MODE A: USING THE FRONT PANEL

1. Repeat the procedures from 1 to 3 of "ADJUSTING THE TIME CYCLE ".

The led "CYC" will blink every ten cycles.

2. Define a number of blinks (n) to be counted (it is recommended to use ≥10). With a chronometer,

measure the time interval for the "n" blinks.

3. This way, the time cycle can be calculated using the equation below:

n

m

t

CYC

.10

=

Where,

CYC = Controller time cycle (ms)

N = Number of blinks of the "CYC" Led.

t

m

= Time interval between "n" blinks.

MODE B: USING AN OSCILLOSCOPE

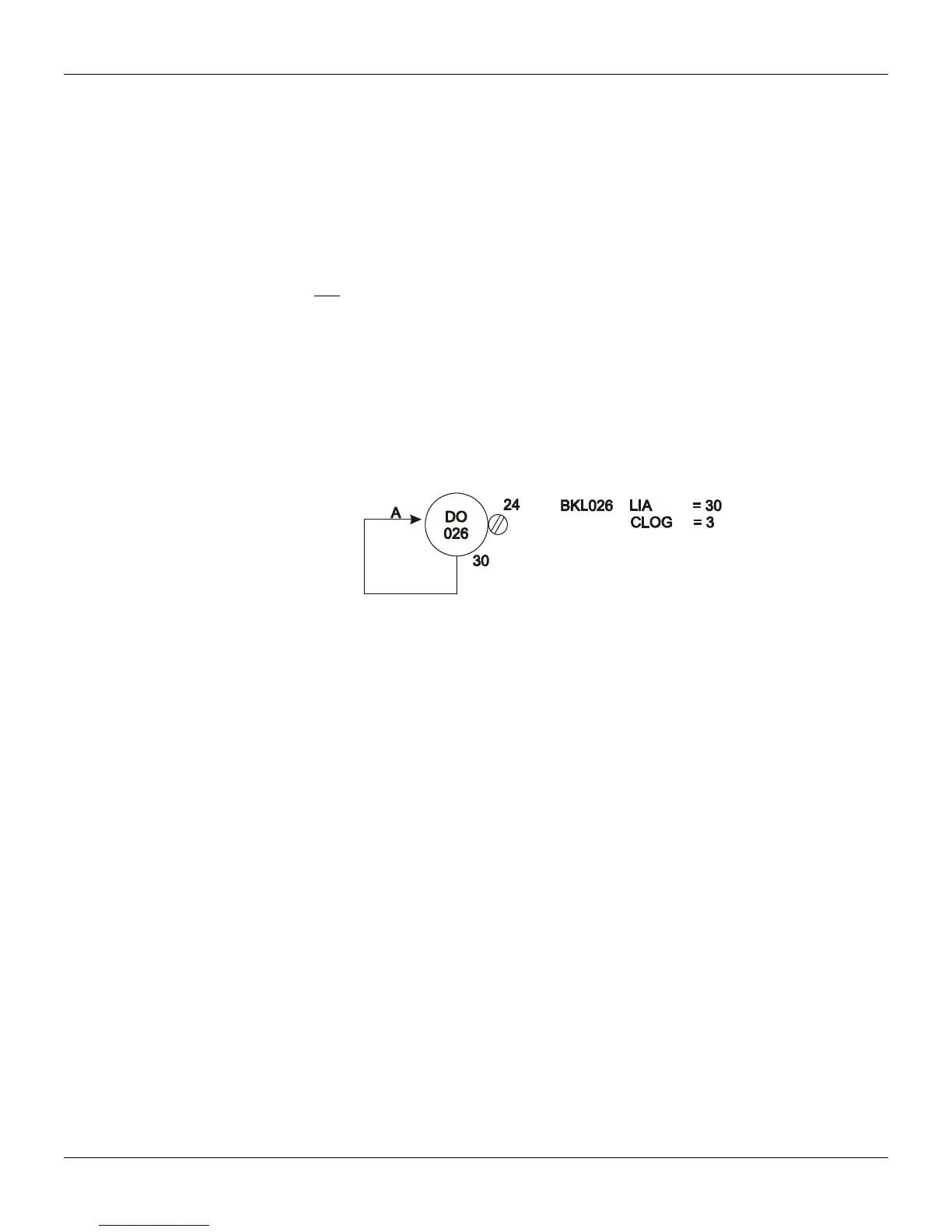

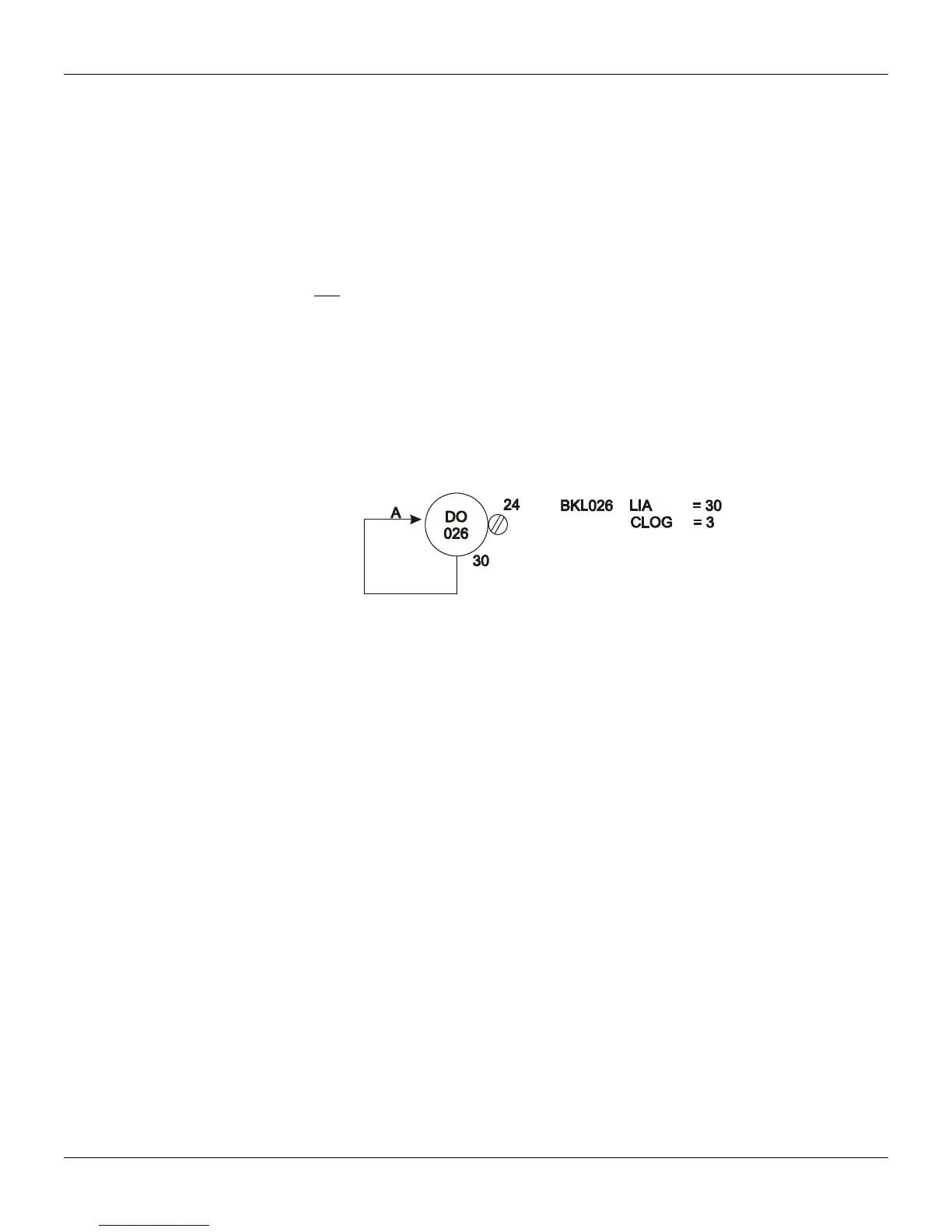

1. Build a strategy with a digital output linked and parameterized as follows:

Fig. 7.2 – Configuration to check the time cycle, using an oscilloscope

2. Download this configuration to the controller.

3. Measure the frequency signal on terminals 23 and 24.

OPC Supervision

Through the OPC Server the CD600s can be integrated with just about any process visualization

software. Moreover, integrating auxiliary software such as autotuning, link to Office applications,

statistical process control, and batch is easy. The industrially hardened ICS2.0P or any other

interface converter can be used to connect the CD600 network to a PC. To connect the CD600Plus

to an Ethernet network, the ENET-710 interface is available.

The CD600 OPC Server accesses the controllers on the EIA-485 network. Multiple users can

simultaneously access the local server in the same workstation or remotely over the Ethernet. This

enables real time data to be shared among workstations eliminating inconsistencies. All of the

information in the controllers is made available to the OPC client applications.

OPC is a widely accepted industry standard client server technology for interchanging parameter

values between applications. OPC eliminates the need for specific drivers for every HMI application.

It opens up a wide, and fast growing, selection of auxiliary software from a vast array

of suppliers. Using the OPC as a bridge, data can be exchanged with other sub-systems. The

configuration tool automatically generates the communication configuration for the OPC server.

Loading...

Loading...