Chapter 9 Maintenance Alpha Compact 32708612

Version: 14.12.2012 page 121 of 135

Six month Maintenance (After Approx. 1000 Hours of Operation)

Requirements

Labeler is free of energy (free of power and *²air pressure)

No supply of products

Required Resources

Vacuum Cleaner

Instruction

Please arrange the six-month maintenance as follows.

Yearly Maintenance (After Approx. 2000 Hours of Operation)

Requirements

Labeler is free of energy (free of power and *²air pressure)

No supply of products

Instruction

Please arrange the yearly maintenance as follows.

*² Only if system is equipped accordingly.

.

Step Procedure

1

Replace the *²air filter elements (if available).

2

Clean the system cover outside and *²the protective cabinet (if availa-

ble) inside using an industrial vacuum cleaner.

Do not use air pressure from the shop air supply to blow dust from the

machine. There is a possibility that this air can contain water and traces

of oil, which can damage the electrical components in your machine!

Step Procedure

1

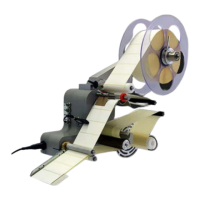

Examine label liner rewinder and the friction clutch for excessive wear.

Check all timing belts for wear and correct tension. Exchange all parts

that are necessary for a correct function..

2

Check all moving parts for wear and bearing clearance.

3

Check all electric connectors and connecting devices.

4

Check all pneumatic connections.

Loading...

Loading...