Chapter 6 Installation and Initial Operation Alpha Compact 32708612

Version: 14.12.2012 page 67 of 135

Instruction

Please adjust the Wipe-On system as follows.

Step Procedure

1

Please put a product directly below the peeler bar. The conveying system

has to be switched-off.

2

Loosen the screw of the roller holder and adjust the roller approx.to product

height.

Remark that longer labels always need a bigger distance of

the pusher roller.

3

Fix the screw and let a few products pass the labeler (without application) to

check the adjustment.

4

Switch-on the labeler at on- /off-switch.

5

Please adjust the speed of label feed to the speed of products.

6

Make some test-applications and correct the application result if necessary

(see p.123).

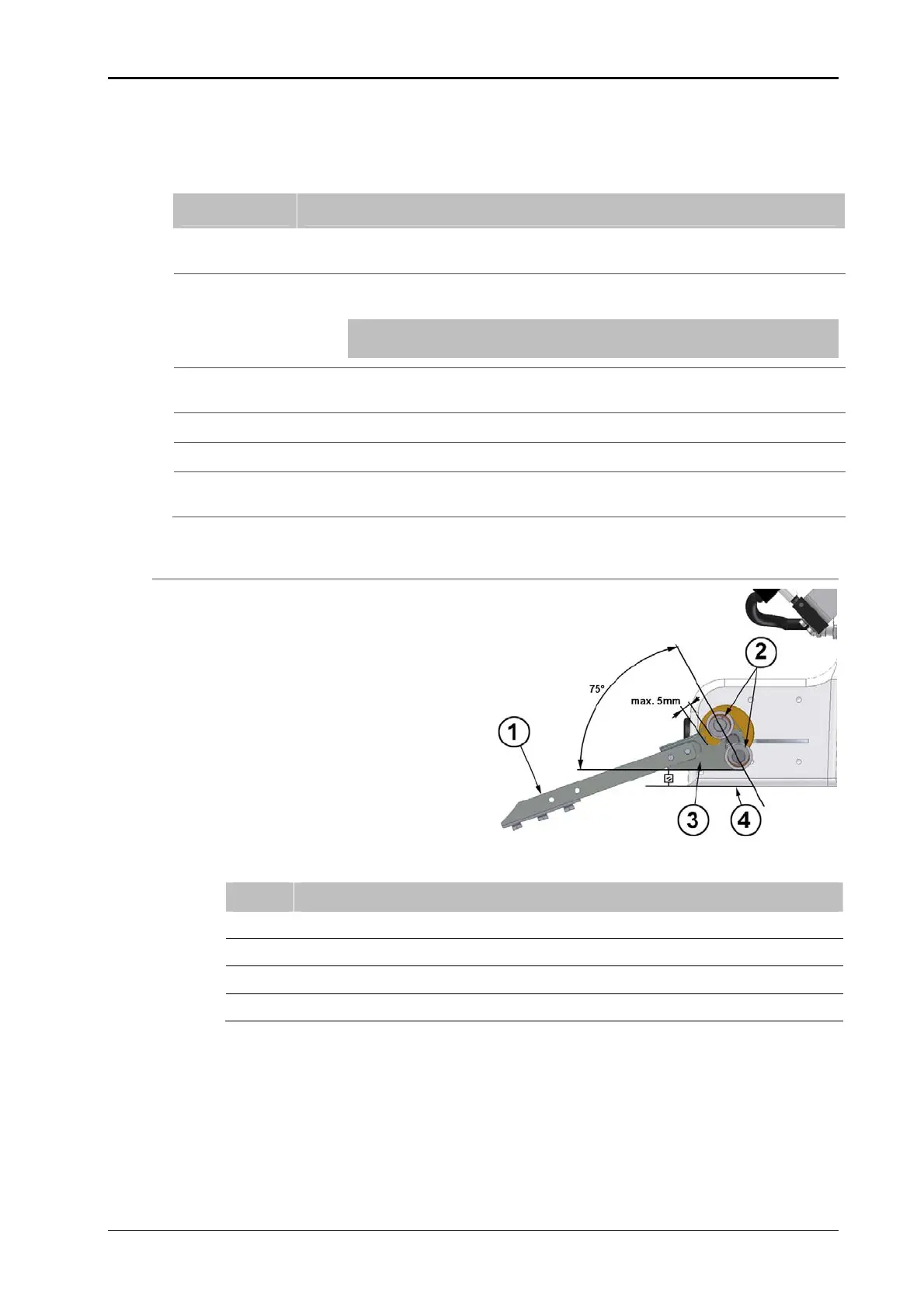

Adjust peeler blade to the deflection rollers

Fig.: 6-25: Adjust peeler blade

Nr. Bezeichnung

1

PEELER BLADE

2

DEFELECTION ROLLERS

3

PEELER BLADE BRACKET

4

LOWER EDGE COVER

To decrease the danger of being crushed between peeler blade’s mounting and deflection

roller, the gap may not be larger than 5 mm. To ensure this, an angle of 75 ° between

peeler blade’s mounting and deflection roller has to be kept. In our factory, a mounting

device is used for alignment. By means of this device, the peeler blade’s mounting is

aligned parallel to the lower edge of the cover. If this factory setting is changed for adap-

tion to the customer’s conveying system, the maximum distance of 5mm has to be recon-

structed. To adjust the distance, at the bottom side of the cover, two clamping screws are

loosened and then the extender bearing is turned into the appropriate position.

Loading...

Loading...