Chapter 6 Installation and Initial Operation Alpha Compact 32708612

Version: 14.12.2012 page 72 of 135

Requirements

- Labeler is turned on

- No transportation of products

Required equipment:

- Screw driver G00

- Screw wrenchs 14 and 12

Instructions

Please adjust the air assist as follows

Step Procedure

1

Check firstly if the air assist beams hits appr. 10 mm behind the leading

edge of the tamp (see Fig.: 6-29).

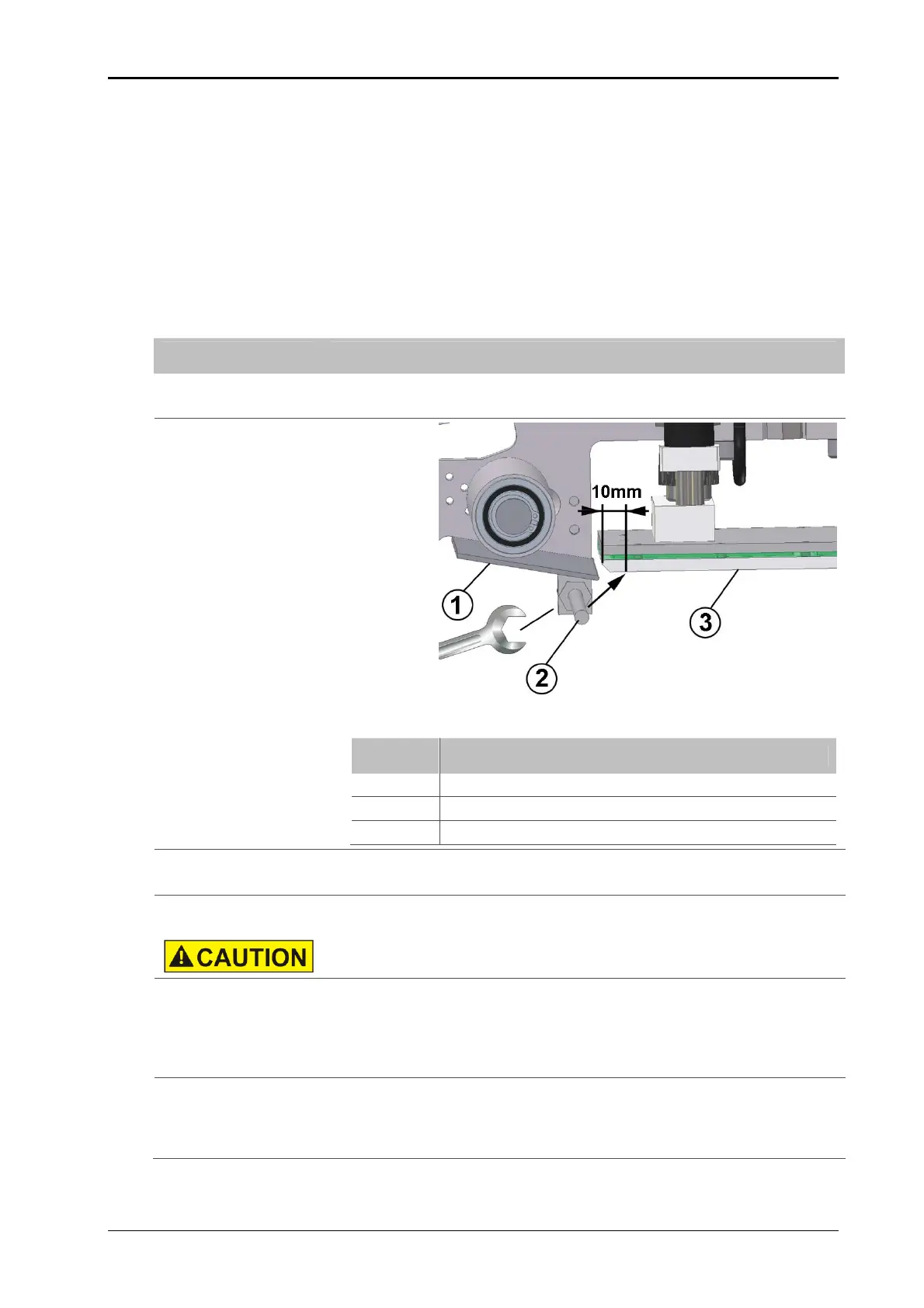

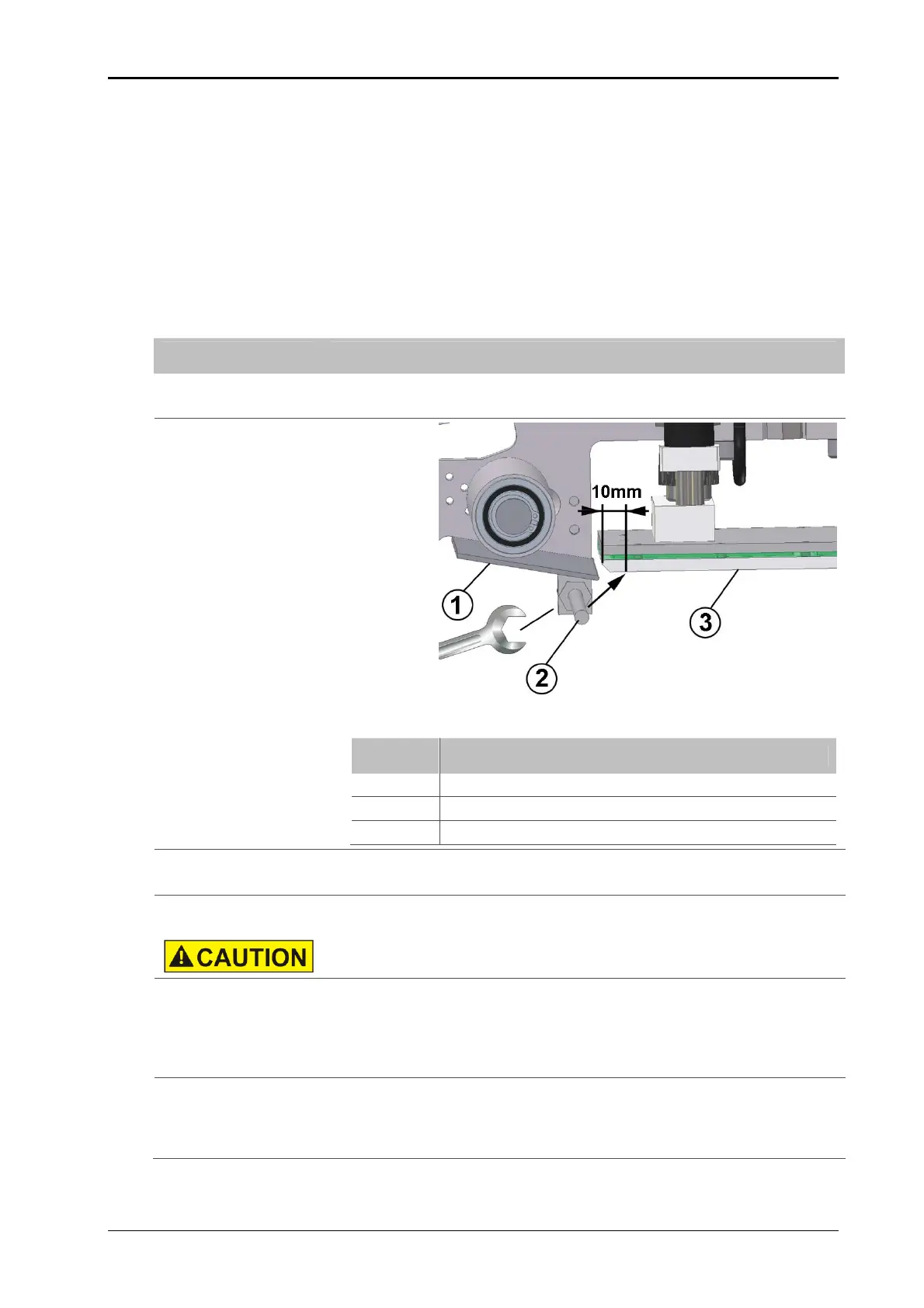

Fig.: 6-29: Air assist unit (side view)

No. Description

1

PEELER BLADE

2

AIR ASSIST TUBE

3

TAMP PAD

2

If an adjustment is necessary, the counter nut has to be unscrewed and

the tube has to be turned into position and then arrest the nut again.

3

Following adjustment can only be arranged during a label feed and re-

quired a lot of experience.

DANGER OF BEING CRUSHED IN! Keep away from tamp.

4

Push the [ENTER]-button of the printer in order to feed a label.

Regulate in the meantime the air beam by the flow control valve at the

bottom side of the stainless steel cabinet (see p. 71).

- turning clockwise leads to a weakening.

- turning counter clockwise leads to an amplification of the air jet.

5

Repeat step 4 until the label is pushed safely against the tamp pad.

Search for an adjustment requiring only a little quantity of air pressure.

You will thus reduce the air pressure consumption and you will reduce

possible air rotations.

Loading...

Loading...