Maintenance1715−1/A1

Winterthur Gas & Diesel Ltd.

2/ 2

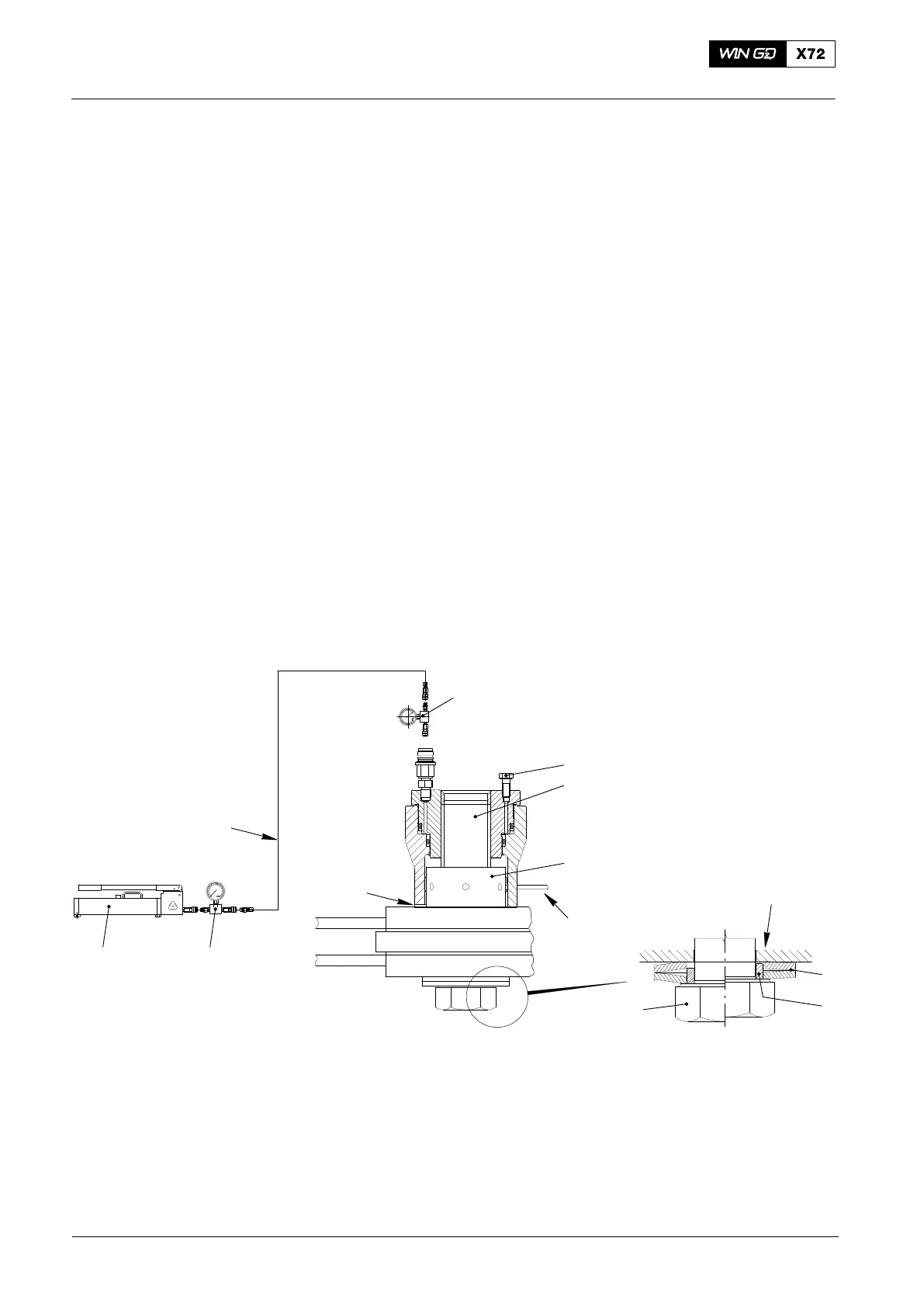

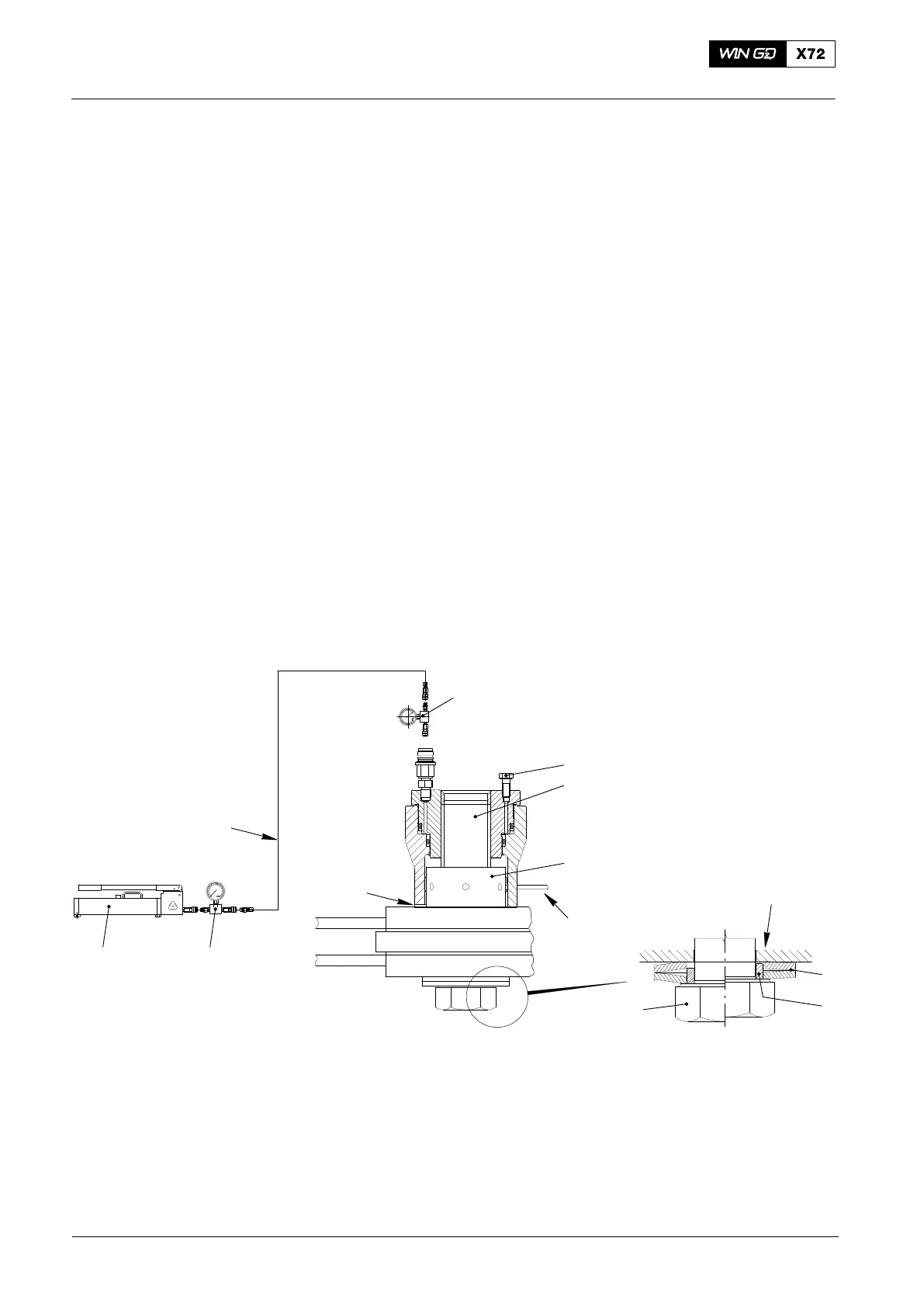

2. Pre-tension Checks

1) Clean the threads of the bolts (2, Fig.1) and the seating surfaces.

2) Apply Molykote paste G to the threads of the bolts (2).

3) Refer to 9403−2 and 9403−4. Attach the pre-tensioning jack and the applicable

equipment as shown in Fig. 2.

4) Apply a tension of 170 bar to the bolt (2).

5) Put the feeler gauge (94122) through the slot (7) to do a check for clearance between

the nut and its seating. If there is no clearance, the bolt tension has not changed and

you can do steps a) and b). If there is a clearance, do step 6).

a) Operate the vent screw (1) to release the pressure to zero.

b) Remove the tools and equipment.

6) If there is clearance, the tension of the bolt has changed since the last check and you

must do steps a) to d) below:

a) Use a round bar (4) to tighten the nut (3).

b) Use the feeler gauge to make sure there is no clearance.

c) Operate the vent screw (1) to release the pressure to zero.

d) Remove the tools and equipment.

Note: The data to loosen the bolts is given in 9403−4.

94931 94934A

2

7

016.704/08

017.672/08

3

94935

5

6

94934A

Fig. 2

1

2

4

Note: Disc springs

must be compressed

2015

Engine Stays with Friction Shims: Pre-tension Checks

Loading...

Loading...