Maintenance

3103−1/A1

Winterthur Gas & Diesel Ltd.

3/ 3

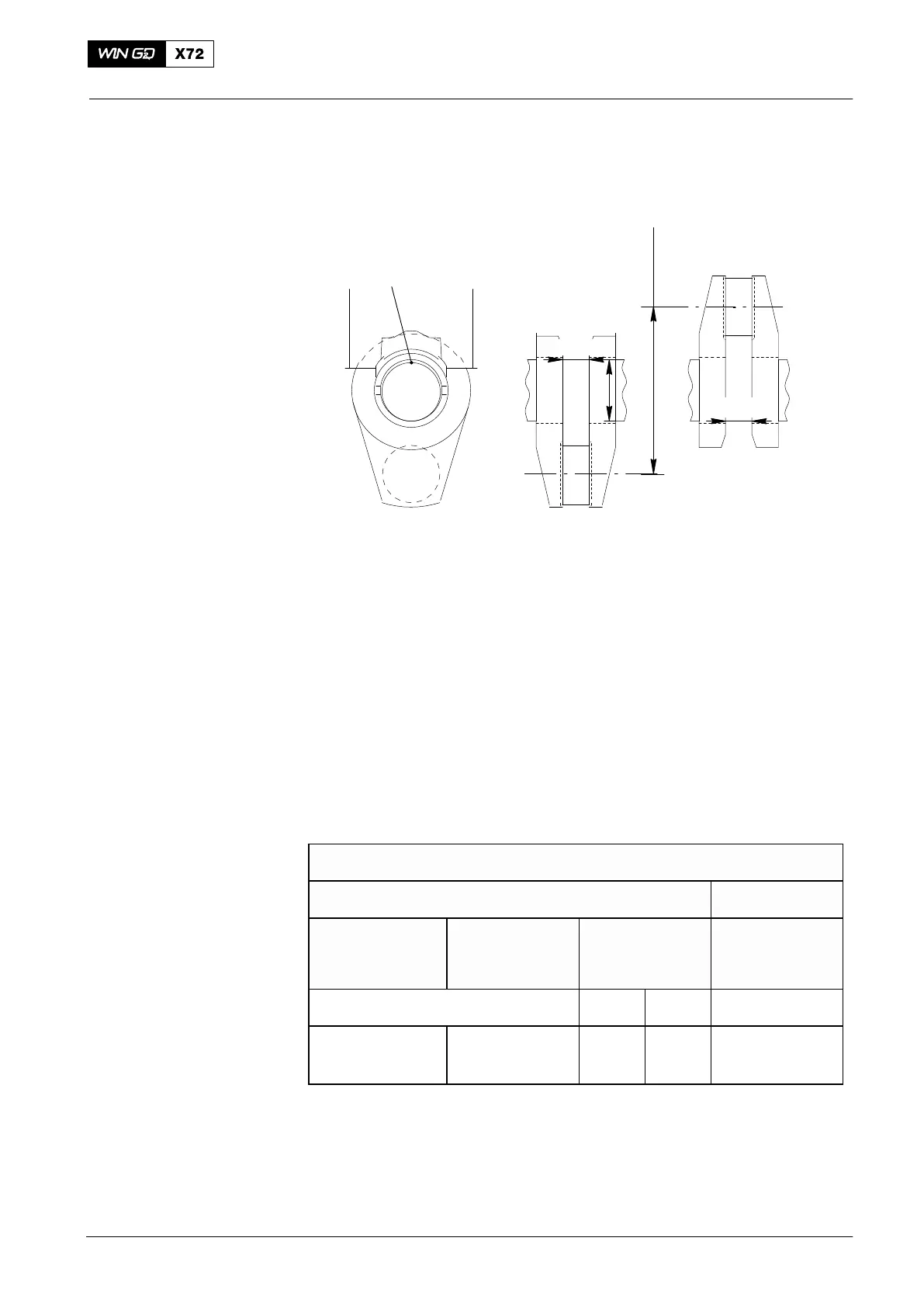

4. Calculate

STROKE

D

94305

nBDC

nTDC

Fig. 3

The difference between the values shown shows the crank deflection during one full

turn of the crankshaft (Fig. 2).

Where values are measured that are more than the maximum permitted limits, the

cause must be found. The necessary procedures must then be done to repair the

problem (defective main bearing, engine stay changed because of hull deformation,

loose hold-down bolts, defective propeller shaft bearings or equipment 94305, etc.).

The limits are applicable for all conditions of ship service after delivery, i.e.:

D The draught and trim are in the limits for usual operation.

D The engine is stopped and is hot or cold.

D If the engine is in a cold condition the tank heating (which is close to or below the

main engine and the pre-heater of the main lubricating oil separator) must not be

in operation for a minimum of eight hours before the procedure given in

paragraph 2.

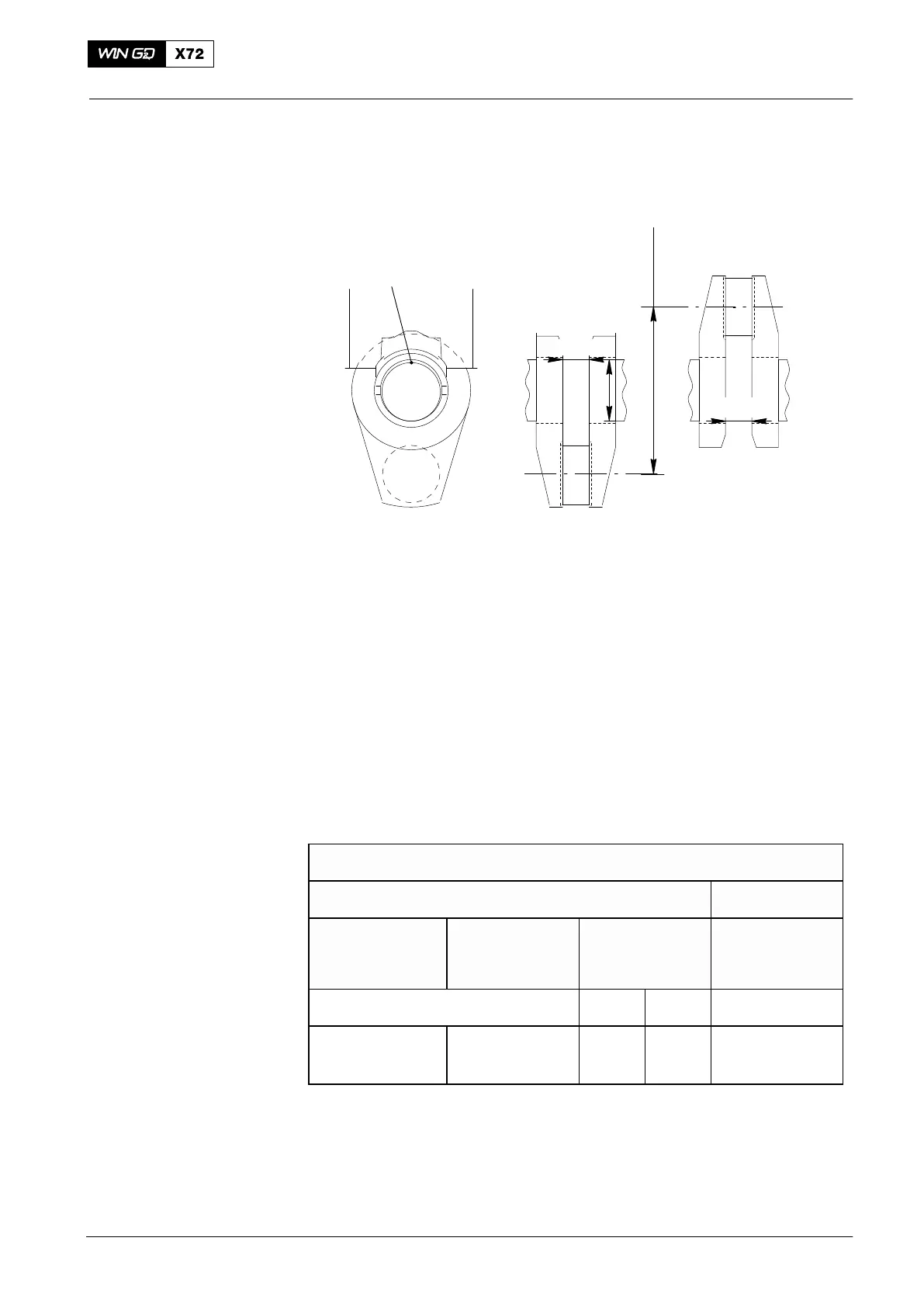

Usual Operation: Crank-web Deflection Limits (mm)

Vertical Horizontal

Cylinder No. 1

(Driving end)

Cylinder No. 2

to next to last

cylinder

Last cylinder

(Free end)

All cylinders

Note

1) Note

2)

0.82

−0.82

0.58

−0.58

0.58

−0.58

0.58

−0.82

0.27

−0.27

1) For engines without torsional vibration damper, or front disc or free end PTO.

2) For engines with torsional vibration damper or front disc or free end PTO.

Speak to WinGD, if the final indications are more than the limits given in the table

above.

2015

Measuring Crank Deflection

Loading...

Loading...