Maintenance4103−2/A1

Winterthur Gas & Diesel Ltd.

4/ 6

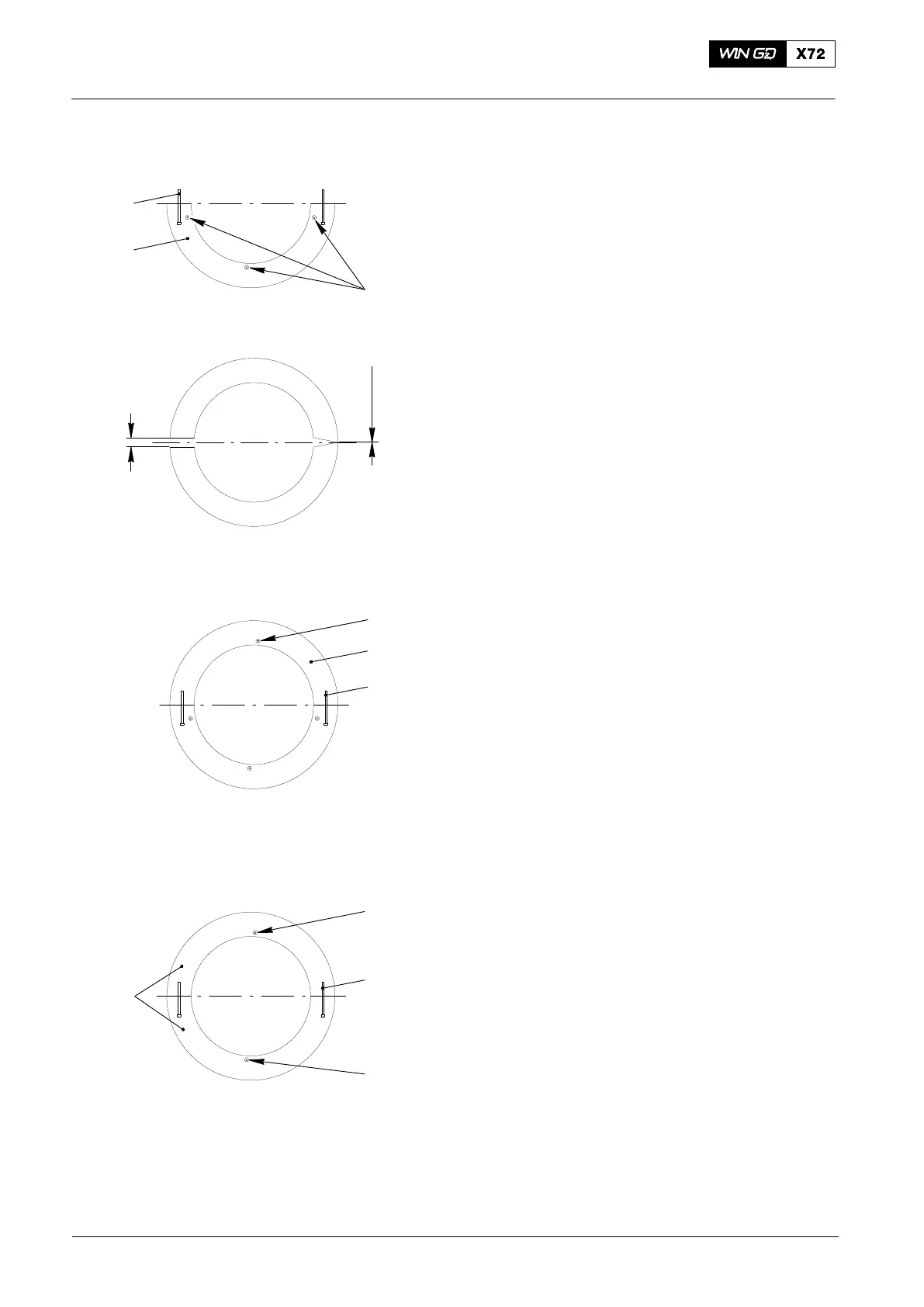

5) Put three flange screws (6, Fig. 4) in

position as shown in the wheel half (1).

Tighten the screws temporarily.

6) Turn the turn the crankshaft to move

the gear wheel half (1, Fig. 5) to the

bottom position.

7) Put the other half of the crankshaft gear

wheel (1, Fig. 6) (with the other two

assembled elastic studs) in position on

the crankshaft flange. Make sure that at

one side, there is no clearance.

8) Measure the clearance between the

two halves of the crankshaft gear

wheel. The clearance must be between

0.16 mm to 041 mm.

Note: If the clearance is not between

0.16 mm and 0.41 mm do not

assemble the gear wheel. Refer to

paragraph 2, step 5.

9) Adjust the top half of the crankshaft

gear wheel (1) to get an equal

clearance on each side.

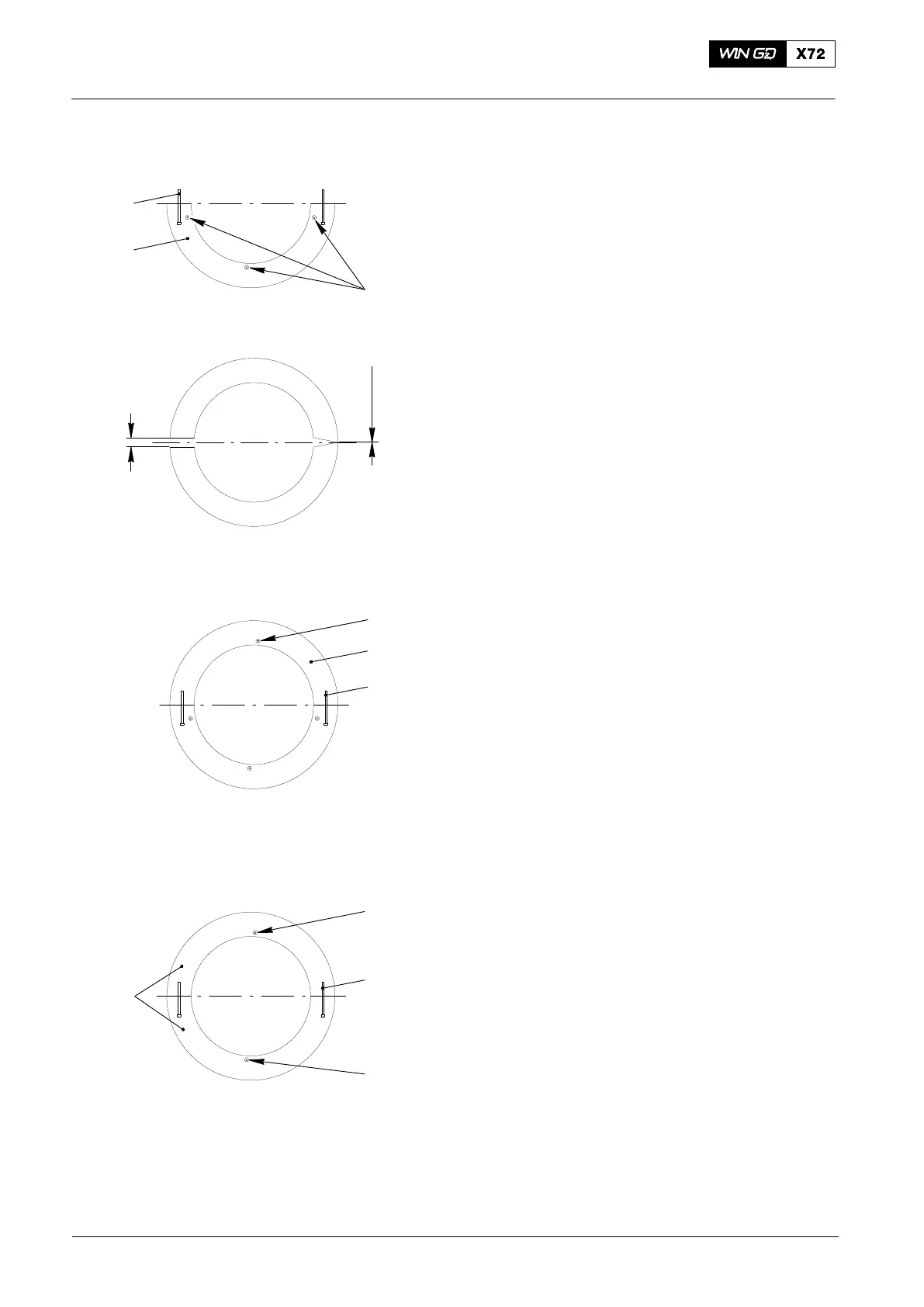

10) Lightly tighten the castle nuts on the

elastic studs (3, Fig. 7).

11) Put a flange screw (6) in the center

position in the top half of the crankshaft

gear wheel (1). Temporarily tighten the

flange screw.

12) Remove the two outer flange screws

from the bottom half of the crankshaft

gear wheel (1). Make sure that only the

top and bottom flange screws (6,

Fig. 8) stay in position.

13) Make sure that there is no clearance on

the seating surfaces between the

crankshaft gear wheel and the

crankshaft flange.

14) Apply Molykote paste the threads of the

four remaining castle nuts (1, Fig. 3)

15) Install the four remaining castle nuts (1)

to the elastic studs (3).

Note: In step 16), tighten only the castle

nuts that have Molykote paste on

the threads.

16) Use the slugging wrench (94002−60) to

symmetrically tighten the castle nuts.

Use a wrench to hold the opposite

castle nuts (that have a split pin and

Loctite 262 on the threads).

2015

Replacing the Gear Wheel on the Crankshaft

6

3

1

6

3

6

1

Fig. 5

Fig. 6

Fig. 7

Fig. 8

WCH02403

WCH02403

WCH02403

WCH02403

0.16 mm to

0.41 mm

Clearance

0.00 mm

6

1

3

Loading...

Loading...