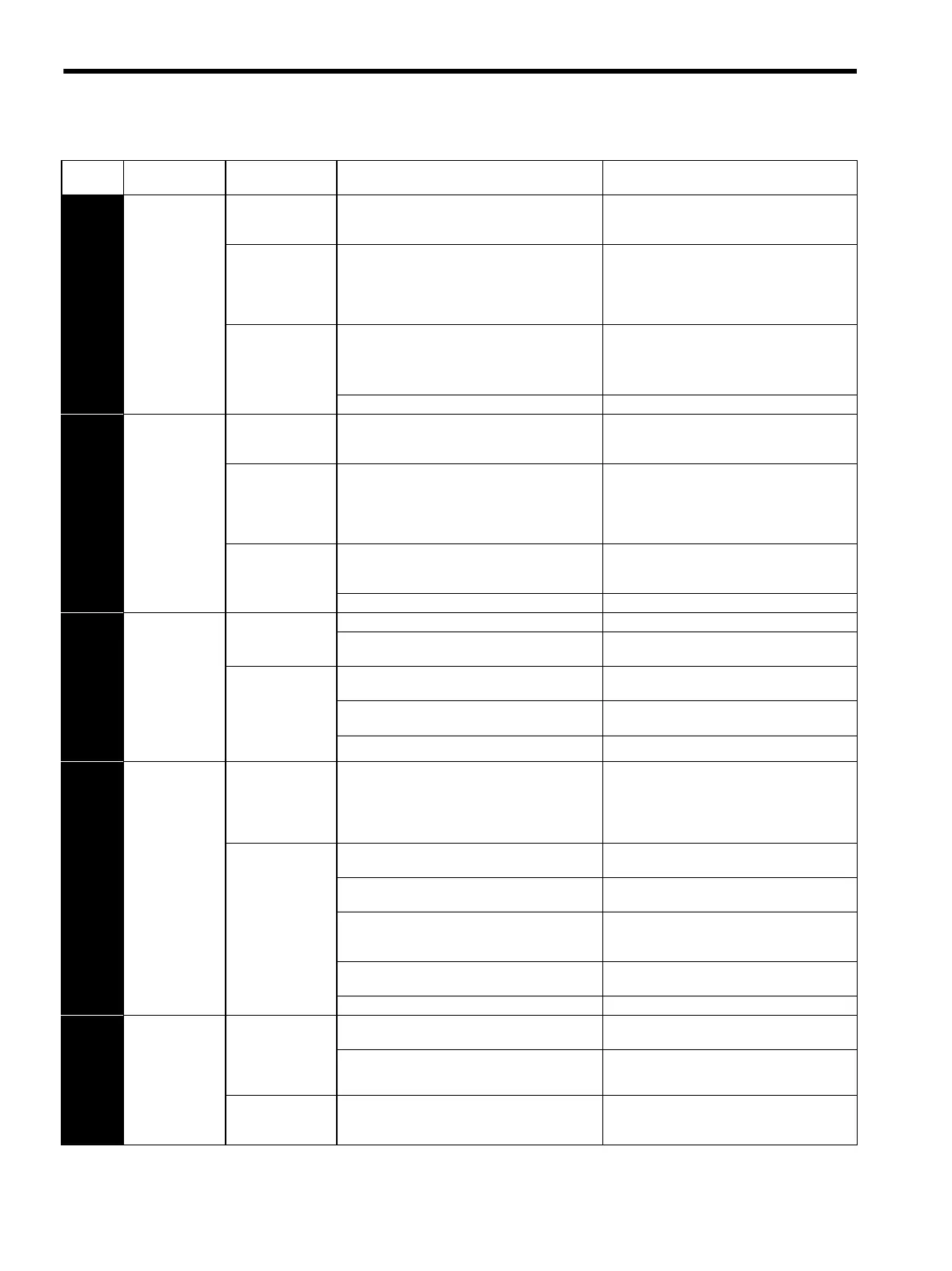

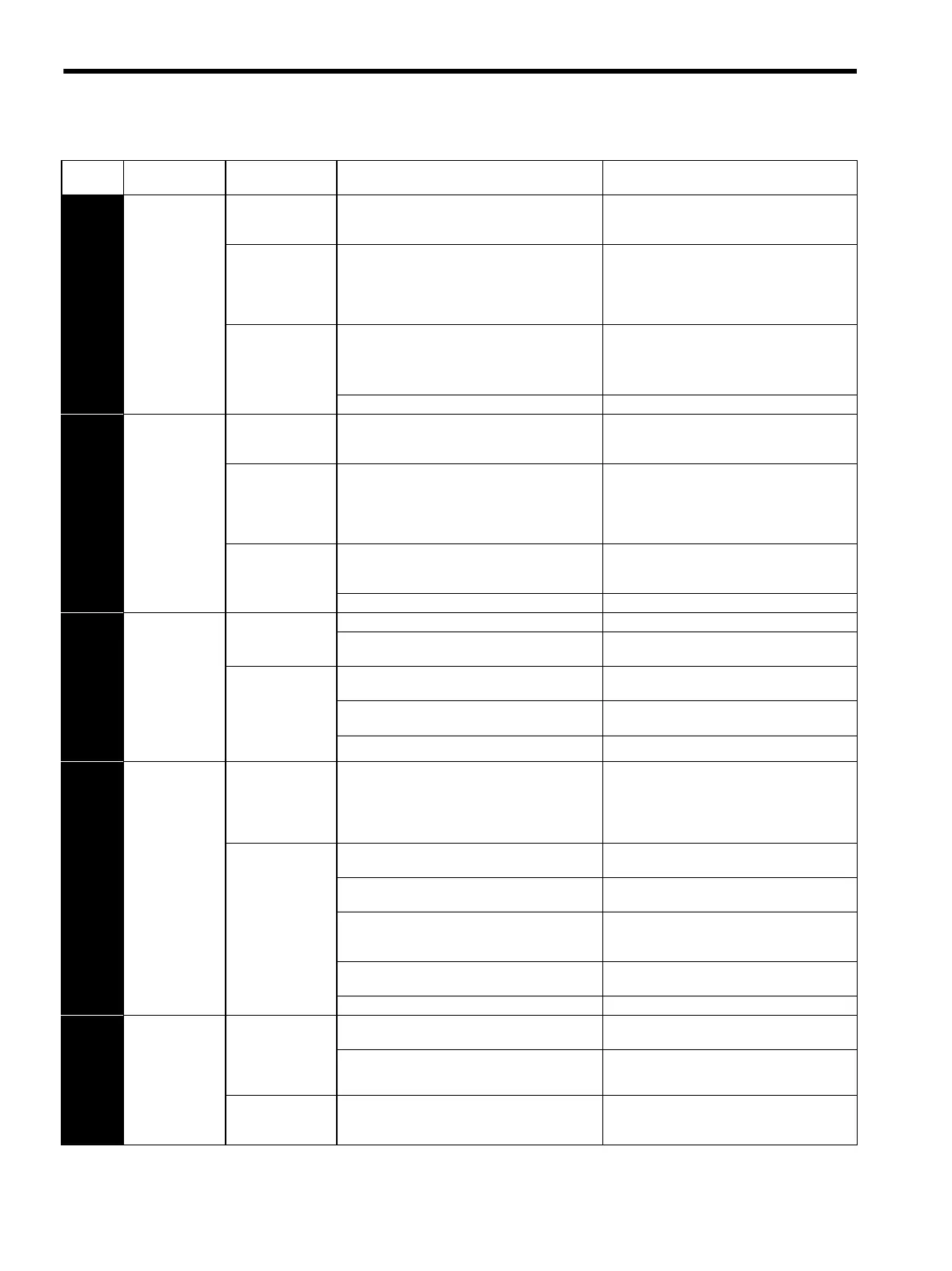

11 Inspection, Maintenance, and Troubleshooting

11.1.3 Troubleshooting of Alarm and Warning

11-10

A.73

Dynamic Brake

Overload

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

servomotor was

running and in a sta-

tus other than servo

OFF.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

servomotor was

running in servo

OFF status.

The rotating energy at a DB stop exceeds the DB

resistance capacity.

cReduce the motor speed,

dReduce the load moment of inertia, or

eReduce the number of times of the DB stop

operation.

A SERVOPACK fault occurred. Replace the SERVOPACK.

A.74

Overload of

Surge Current

Limit Resistor

(Detected when

the number of

times that the

main circuit’s

power is turned

ON or OFF more

than 10 times/2

seconds.)

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred during

operations other

than the turning

ON/OFF of the

main circuit.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred at the

main circuit power

supply ON/OFF

operation.

The surge current limit resistor operation frequency

at the main circuit power supply ON/OF operation

exceeds the allowable range.

Reduce the number of times that main circuit’s

power supply can be turned ON/OFF to 5 times/

min. or less.

A SERVOPACK fault occurred. Replace the SERVOPACK.

A.7A

Heat Sink

Overheated

(Detected when

the heat sink

temperature

exceeds 100 ×

°C.)

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK fault occurred. Replace the SERVOPACK.

The overload alarm has been reset by turning OFF

the power too many times.

Change the method to reset the alarm.

Occurred when the

main circuit power

supply was turned

ON or while the ser-

vomotor was run-

ning.

The load exceeds the rated load.

Reconsider the load and operation conditions, or

reconsider the servomotor capacity.

The SERVOPACK ambient temperature exceeds

55°C.

The ambient temperature must be 55°C or less.

A SERVOPACK fault occurred. Replace the SERVOPACK.

A.81

Encoder

Backup Error

(Detected on the

encoder side.)

(Only when an

absolute encoder

is connected.)

Occurred when the

control power sup-

ply was turned ON.

(Setting:

Pn002.2=1)

A SERVOPACK board fault occurred when an abso-

lute encoder is used with the setting for incremental

encoder.

Replace the SERVOPACK.

Occurred when the

control power sup-

ply was turned ON

using an absolute

encoder. (Setting:

Pn002.2=0)

Alarm occurred when the power to the absolute

encoder was initially turned ON.

Set up the encoder.

The encoder cable had been disconnected once.

First confirm the connection and set up the

encoder.

The power from both the PG power supply (+5 V)

and the battery power supply from the SERVO-

PACK is not being supplied.

Replace the battery or take similar measures to

supply power to the encoder, and set up the

encoder.

An absolute encoder fault occurred.

If the alarm cannot be reset by setting up the

encoder again, replace the encoder.

A SERVOPACK fault occurred. Replace the SERVOPACK.

A.82

Encoder

Checksum

Error

(Detected on the

encoder side.)

Occurred when the

control power sup-

ply was turned ON

or during an opera-

tion.

A fault occurred in the encoder and was detected by

encoder self-diagnosis.

Set up the encoder. If this alarm occurs fre-

quently, replace the servomotor.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred when the

SEN signal turned

ON.

A fault occurred in the encoder and was detected by

encoder self-diagnosis.

Set up the encoder. If this alarm occurs fre-

quently, replace the servomotor.

Table 11.3 Alarm Display and Troubleshooting (Cont’d)

Alarm

Display

Alarm Name

Situation at Alarm

Occurrence

Cause Corrective Actions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...