4Touchscreen Operation

Operation Manual 65

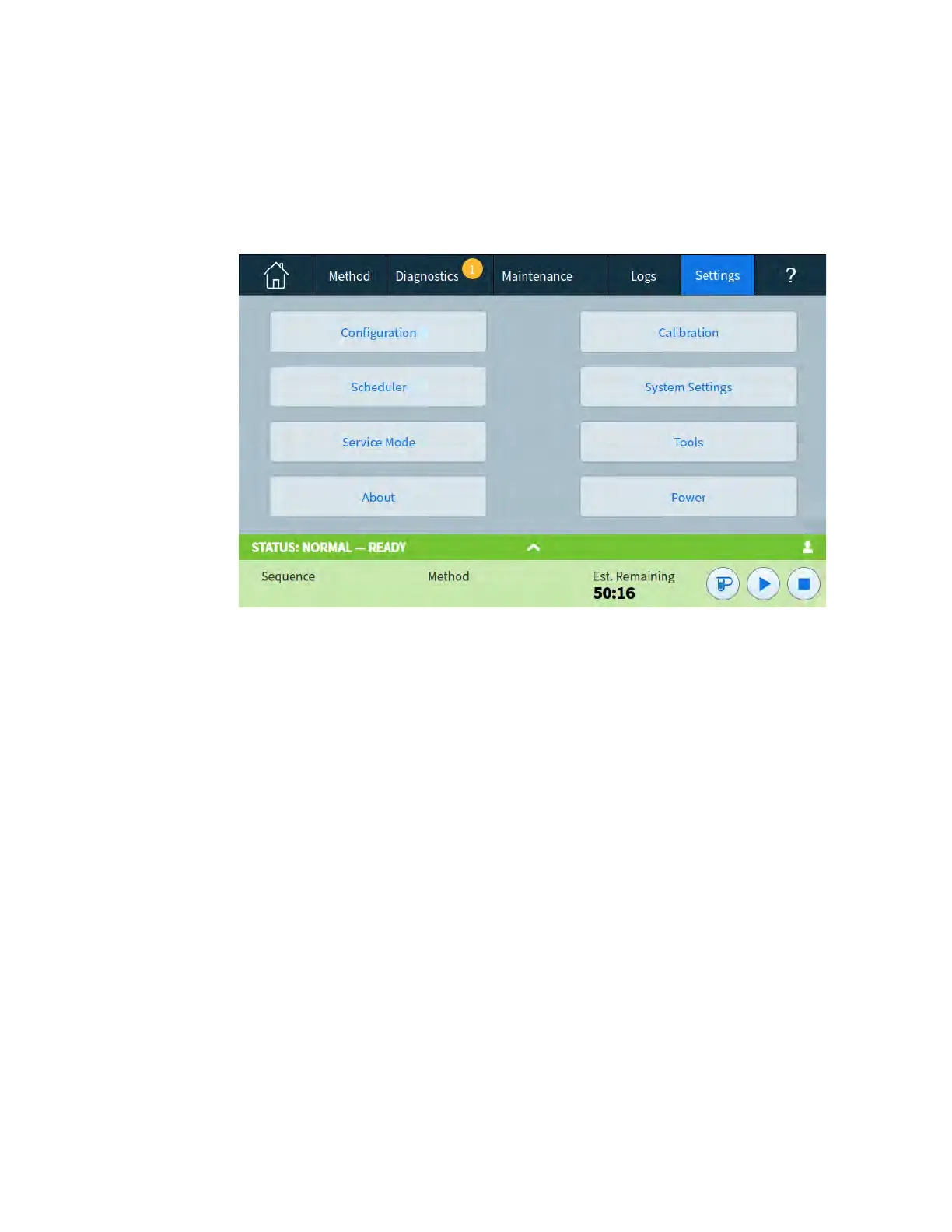

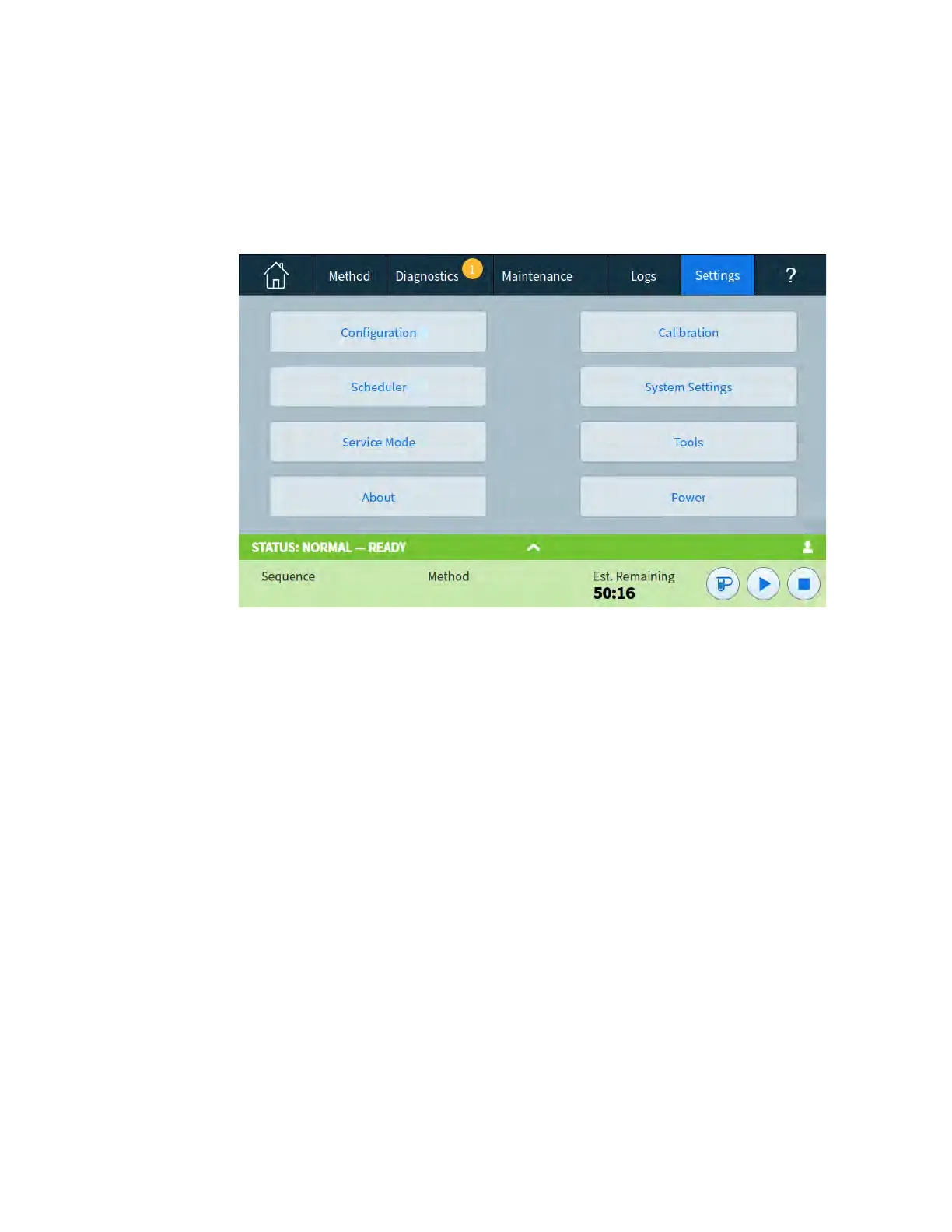

Settings View

The Settings View provides access to instrument configuration functions, scheduler functions,

service mode settings, calibration settings, system settings, system tools, power controls

(restart or shutdown) and system details. See Figure 24.

Figure 24. Settings view

See “Settings” for more details.

Loading...

Loading...