5 - 27

HEAD DISTRIBUTION

VALVE SEAT CHECK

The following process is applied to all valves and valve seats

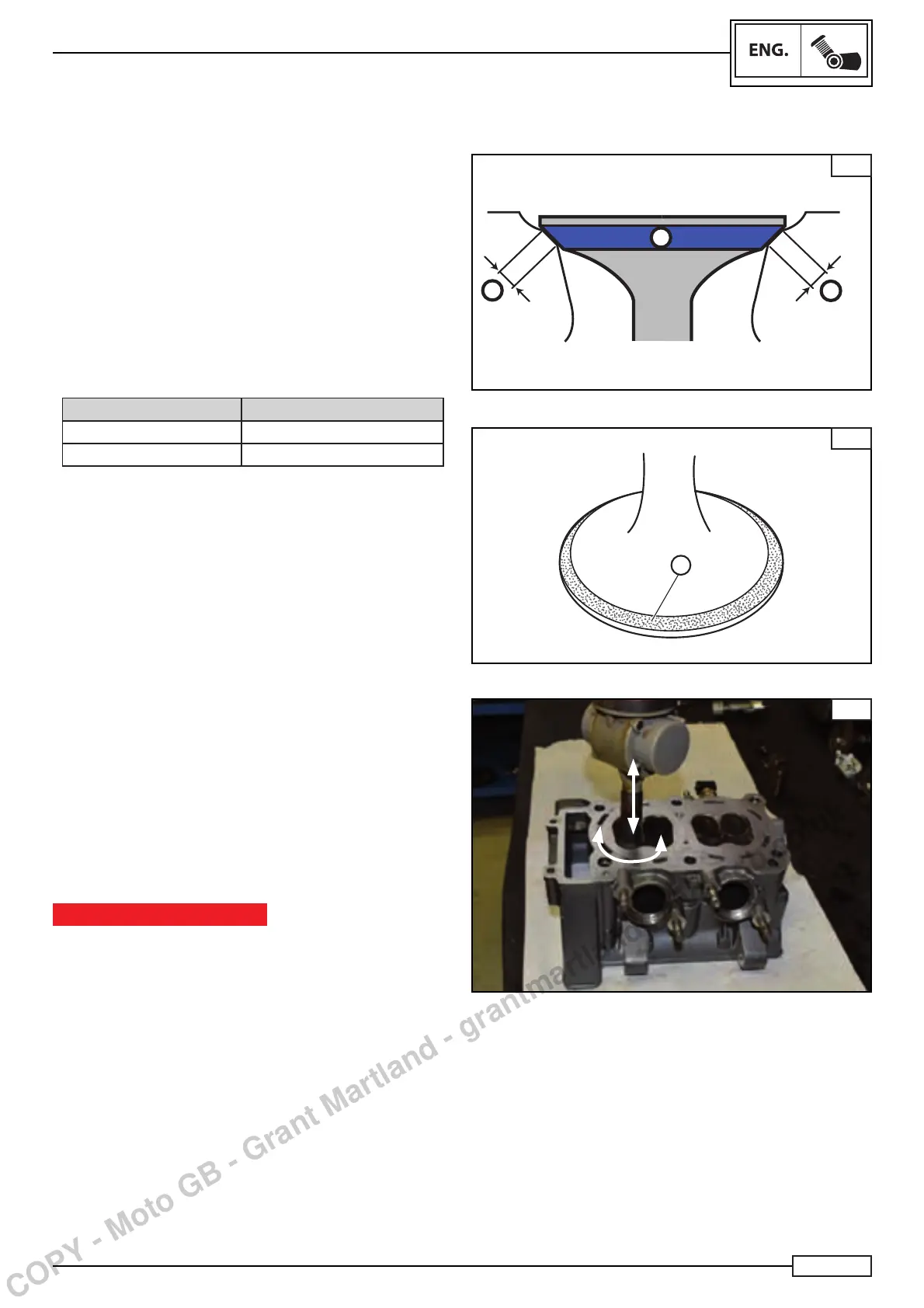

Fig. H

Eliminate:

• carbon deposits

(from the contact surfaces and valve seat (A)

Check:

• the valve seat (A)

If there are marks/signs of wear, replace the head.

Measure:

• the width of the valve seat (A)

If outside specifi cations, replace the head.

Valve Width of the valve seat (A)

Intake 1~ 1.1 mm

Exhaust 0.9 ~ 1.1 mm

1. Apply some blue colorant (Dykem) for mechanics to the

contact surface of the valve (B).

2. Install the valve in the head.

3. Push the valve into the guide and against its seat to leave a

well-defi ned mark.

4. Measure the valve seat width

NOTE:_________________________________

Where the valve seat and valve face are in contact with one

another

, the Prussian blue liquid will have been removed.

Lap:

• the valve contact surfaces

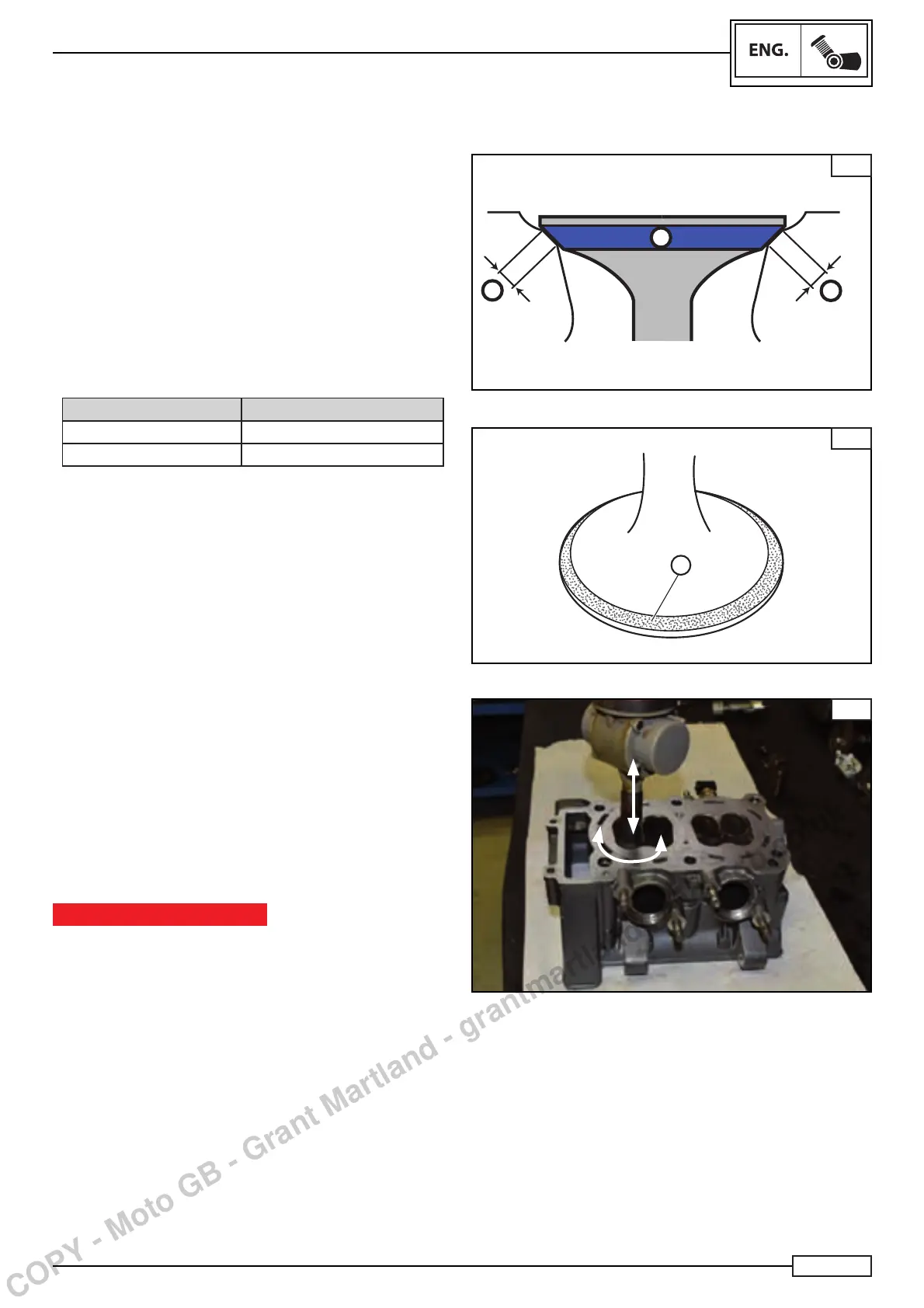

• the valve seat Fig. L

NOTE:_________________________________

After replacing the head or the valve and the relevant guide,

it is necessary to lap the seat and contact surfaces of the

valve.

• Apply a paste for rough lapping of the valve contact surfa-

ces (C) Fig. I

IMPORTANT NOTICE

Do not allow the lapping paste to enter the area between the

valve stem and the guide.

• Apply molybdenum disulphide oil to the valve stem.

• Install the valve in the head.

• Turn the valve until the contact surface and the seat have

been polished evenly

, then remove all the lapping paste.

NOTE:_________________________________

To get the best results from lapping, gently tap on the valve

seat while turning it forwards and back manually Fig. L

A

A

B

H

C

I

L

COPY - Moto GB - Grant Martland - grantmartland@motogb.co.uk

Loading...

Loading...