5 - 48

Install:

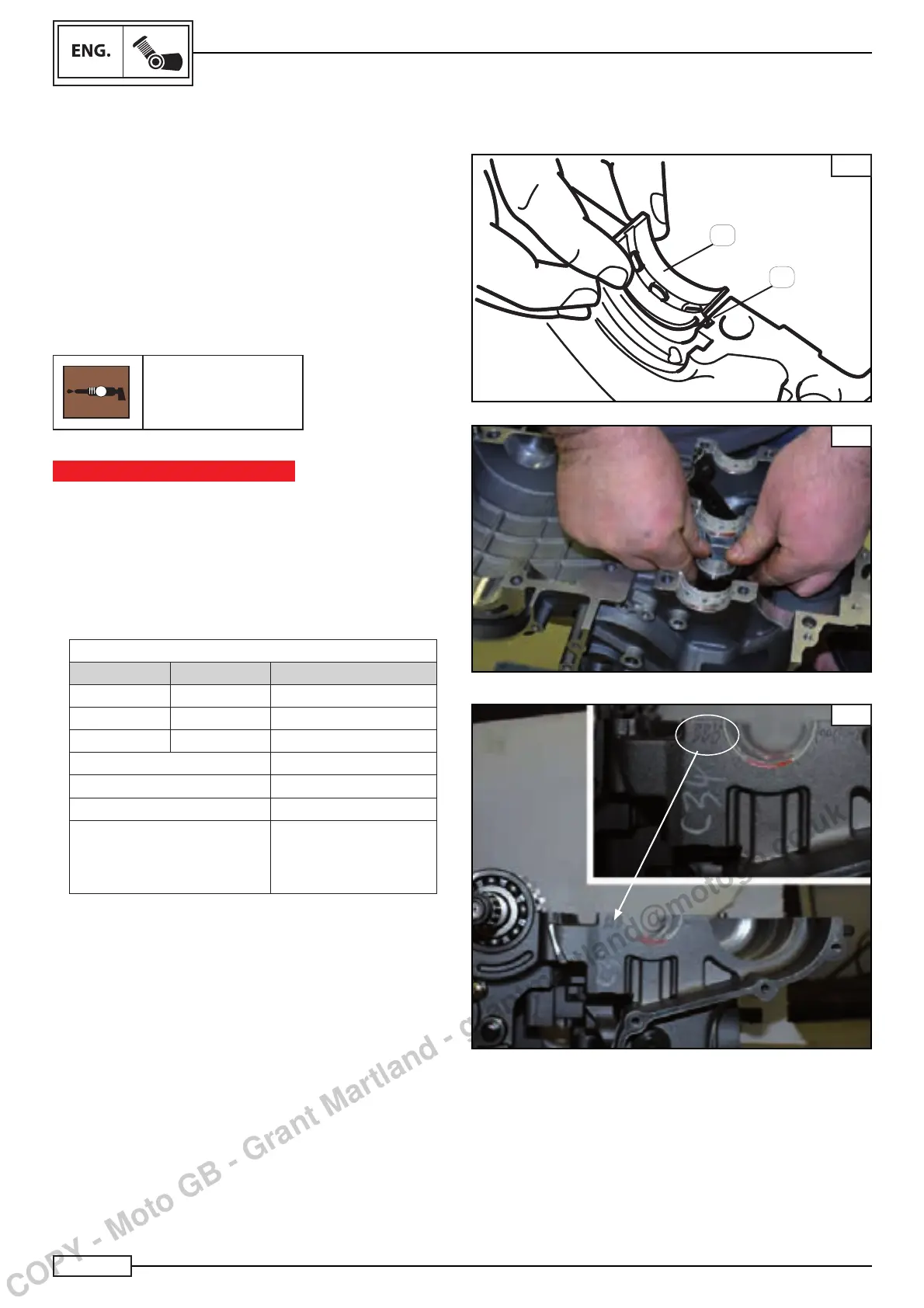

• clean the main bearing shells (6)

• connecting rod main bearing shells:

• install the connecting rod main bearing shells in the relevant

seats in the top and bottom base.

NOTE:_________________________________

Align the projections of the main bearing shells with the

slots in the top base Fig. A.

Use copper grease for assembly.

G

Sintofl on Grease

IMPORTANT NOTICE

Do not get the main bearing shells mixed up.

To achieve the correct clearance between the connecting

rod support and the bearing shells and to prevent engine

damage, the bearing shells must be installed in their origi-

nal positions.

• The crankshaft bearing shells are in different sizes, marked

with different letters and colours, as shown in the table.

MAIN BEARING SHELLS

STD COLOUR THICKNESS

A Green 1.5(0/0 + 0.003) mm

B Blue 1.5(0/0 + 0.006) mm

C Yellow 1.5(0/0 + 0.009) mm

Ø std seat A green Ø 41(0.007+0.14)

Ø std seat B blue Ø 41(0+0.007)

Ø std seat C yellow Ø 41(0.014+0.021)

Ø std seat only A Ø 41(0/+0.007)

B Ø 41(0.007+0.014)

C Ø 41(0.014+0.021)

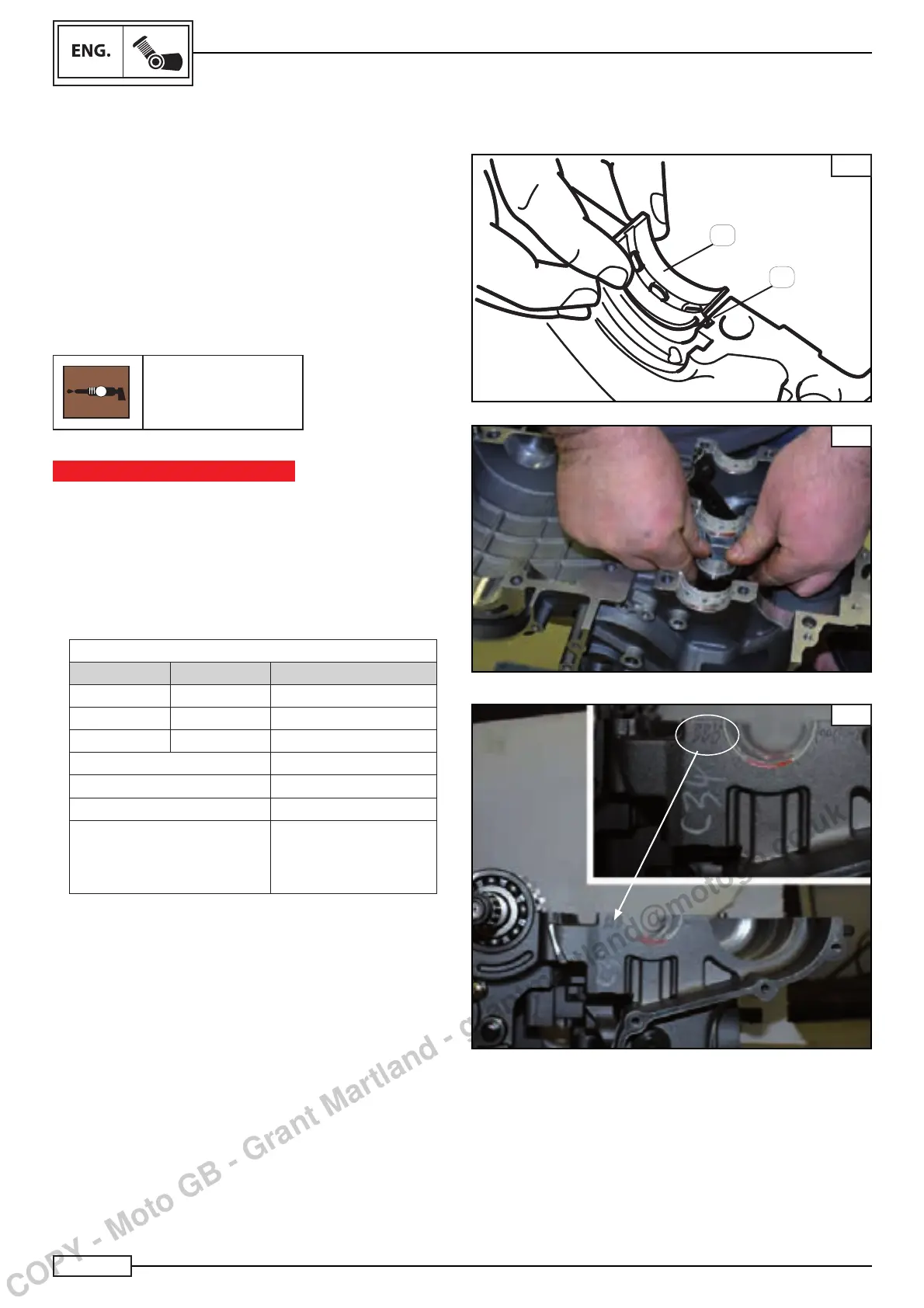

• The support bearing layout is shown on the bottom casing,

as illustrated in Fig. C.

NOTE:_________________________________

In case of replacement of the drive shaft, it is necessary to

replace the connecting rod main bearing shells.

CRANKCASE

MAIN BEARING SHELL AND DRIVE SHAFT INSTALLATION

B

A

6

A

C

COPY - Moto GB - Grant Martland - grantmartland@motogb.co.uk

Loading...

Loading...