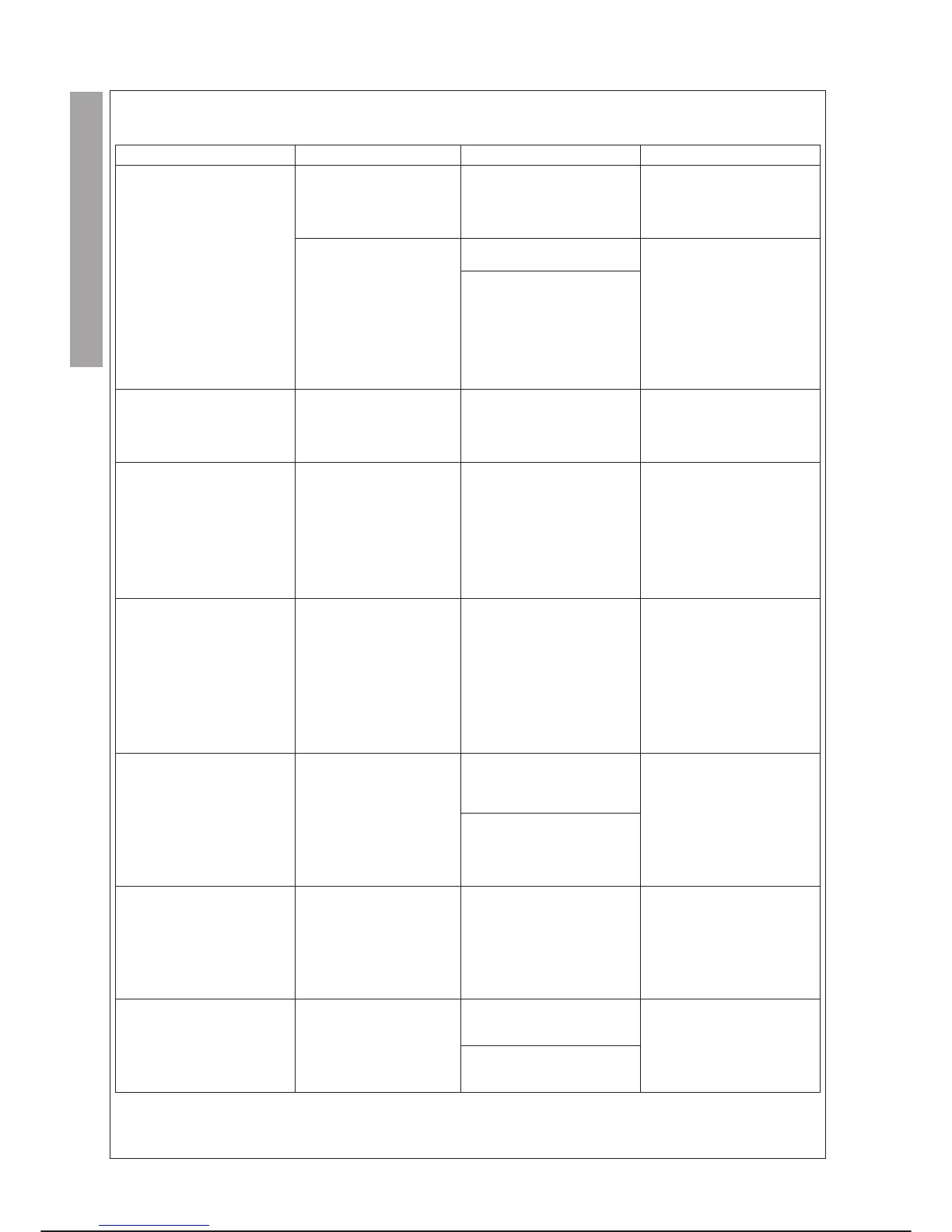

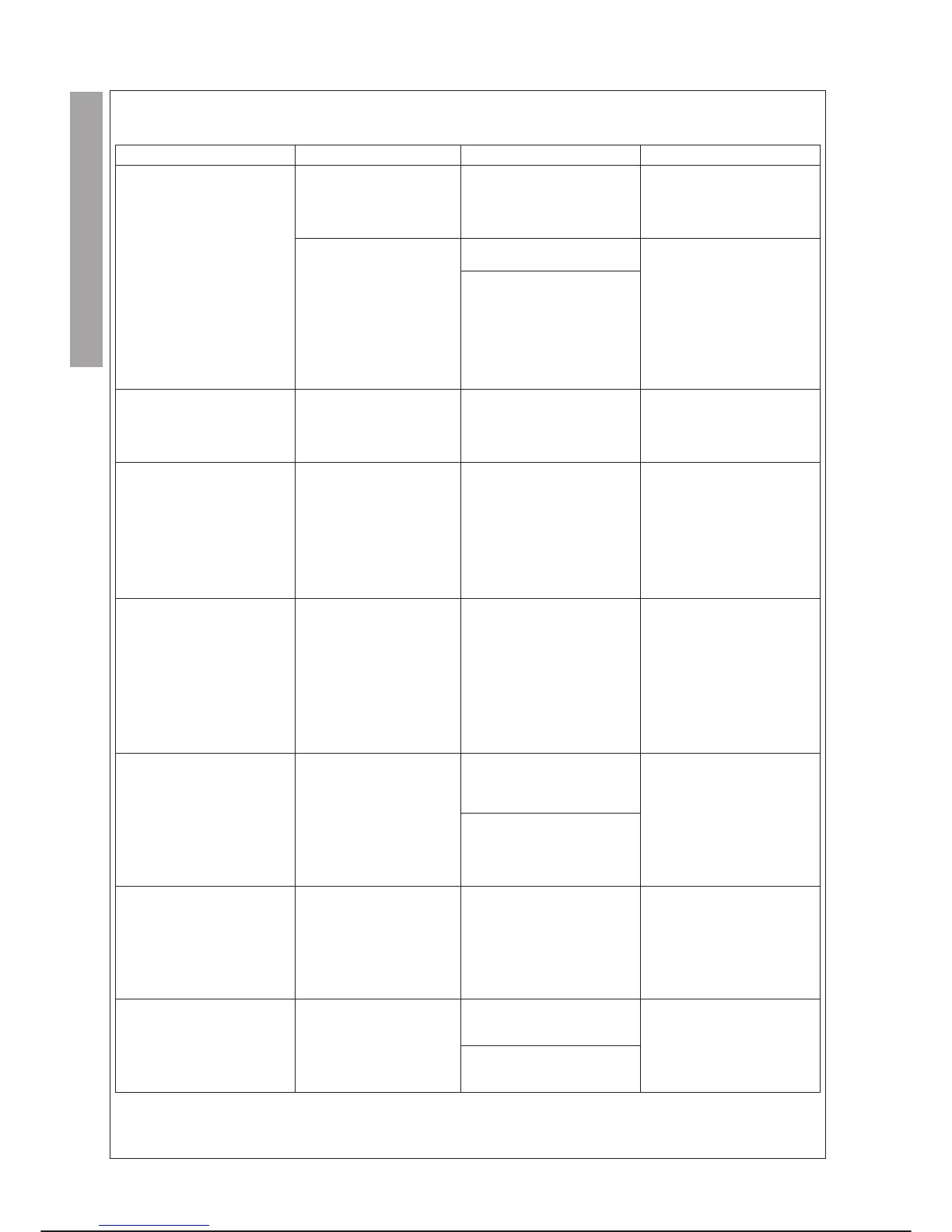

TROUBLESHOOTING INDICATIONS

Alarm/Warning Context Cause/Remedy References

28707-10:

Safety chain circuit open

SAU2

Faulty (SFT led on)

Check circuits of Brakes, Motor

thermal switch, Overtravel

·

Circuit diagram

·

SAU2 Tables

·

Consult cause/remedy with

PCINT programme

Normal operation Check the safety circuit

·

Use of safety circuit test de

-

vice (connector X113)

Check the dynamic braking

enabling contact (C3G-DBU3)

·

C3G Plus and Robot Circuit

Diagram

·

Module C3G-DBU3 circuit on

Circuit diagram

·

Consult cause/remedy with

PCINT programme

61440-10:

SAX xxx motion under no servo

control

After an emergency or

blackout

Parking brakes

oxidised/Perform 4-5

emergency stops at low speed

paying attention to the stopping

spaces needed.

·

Consult cause/remedy with

PCINT programme

63492-11:

SAX xxx drive brake locked

Executing the DRIVE ON

command

·

Check for the presence of 25 V

on power device G100

·

C3G Plus and Robot Circuit

Diagram

·

Power contactors closure

check (brakes circuit and

connector X6 SAU2).

·

Short circuits check on

brakes circuit from SAU2 to

motor.

·

SAU2 signals tables on Cir

-

cuit diagram.

·

Consult cause/remedy with

PCINT programme

63493-11.

SAX xxx DC bus or motor cable

short circuit

Executing the DRIVE ON

command or during DRIVE

ON status

Check whether the motor

windings are open or in short

circuit.

Short circuit or open circuit

check on motor wiring from

SAU2 to motor.

If there is no short circuit or

open circuit , replace the Axis

power module.

· C3G Plus and Robot Circuit

Diagram

·

SAU2 signals tables on Cir-

cuit diagram.

·

Consult cause/remedy with

PCINT programme

61442-11:

SAX xxx following error out of

range

During a movement of the

normal automatic work cycle

Unbalancing of motor

phases/check fuses and

impedance of the motor

winding.

·

C3G Plus and Robot Circuit

Diagram

Resolver reading

problems/Check the resolver

windings and annex “22’ DIFF.

2-AXIS I/O INTERFACE

ANNEX”

·

Consult cause/remedy with

PCINT programme

Robot collision with alarm

61442-11: SAX xxx following

error out of range

Robot collision during work

cycle

Calibration position check (for

example, execute instruction

MOVE TO $CAL.SYS).If the

position is not correct, the

system may have calculated a

wrong resolver speed value.

Run the turn_set procedure on

the axes to be positioned.

·

Consult chapter 2 of the

manual, step 11 “TURN_SET

Operation” (for turn_set oper

-

ation)

·

61441-13:

SAX xxx bad resolver

reading

During normal automatic

work cycle

Check the resolver windings

·

C3G Plus and Robot circuit

diagram

·

62468-13:

SAX xxx resolver open or

short circuit

Check the mobile parts of

wiring on board robot

·

Consult cause/remedy of

PCINT programme

MAINTENANCE C3G Plus

7-38 08/0702

problems of operation

Loading...

Loading...