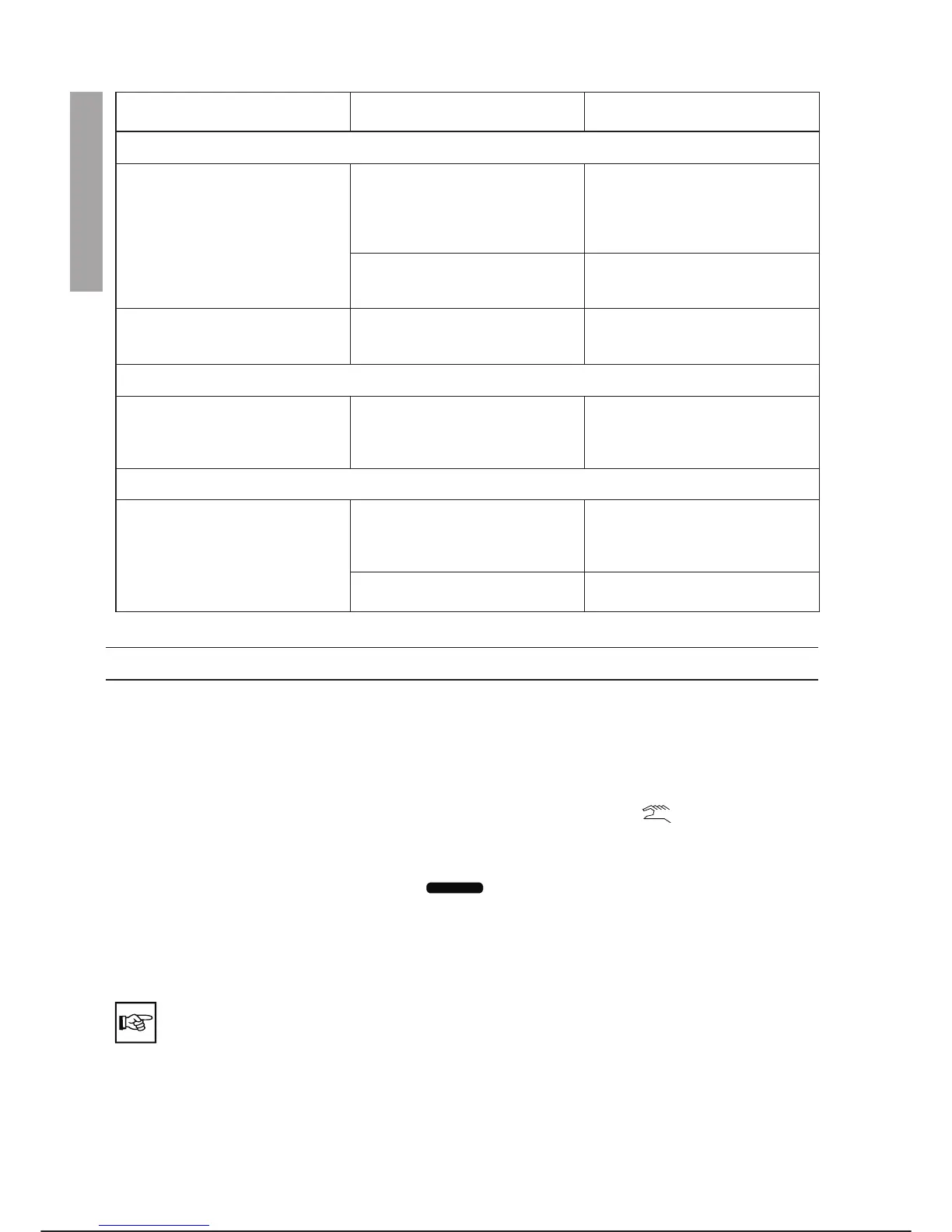

Fault Check Suggestions/Possible causes

3. Checking manual robot movement

The axis intended to be moved is

still

Check that: the Enabling Device

button is pressed and the motors

are on DRIVE ON (led on); the but

-

ton of the axis to be moved is

pressed

Incorrect pressing of buttons, keys

or sequence of commands

If the clamping brackets for trans

-

porting the robot have been re

-

moved

Remove the brackets

The axis to be moved moves badly Check the mechanical geometry of

the axis for distortion or interfer

-

ence

Removed the damaged robot parts

4. Checking TURN_SET

Difficulty in performing the opera

-

tion

Correct command sequence and

correct robot positioning

Carry out the procedure carefully

following the instructions. Consult

chapter 3 of this manual for further

information about commands

5. Check the robot calibration position

The robot does not position cor

-

rectly in the calibration position

(fixed and mobile indexes mis-

aligned, on all or on some axes)

Check that the controller is the one

associated with the robot con-

nected (serial numbers corre-

sponding)

Correctly associate controller and

robot

Check that the robot geometry has

no distortions or interferences

Replace the damaged robot parts

This step of the procedure must be carried out if the word TURN appears in the PTU4 status window. TURN

may be shown following movement of one or more axes of the robot with the C3G

Plus CONTROL UNIT off.

If TURN is not shown on the PTU4 carry out the next step of the procedure.

PROCEDURE

1. Set the status selector on the control panel to the PROGRAMMING position

2.

On the PTU4 select the JNT type of movement using the TYP key

3. Reduce the robot speed to 20% using the key

4.

Pressing the PTU4 Enabling Device button the robot motors turn on (green led lit in correspondence

with the DRIVE ON button)

5. Position the robot aligning the reference notches (fixed and mobile index) of the axis on which Turn_set

is to be performed using the key corresponding to the axis.

After executing the CAT command (Configure Arm Turn_Set) the following messages may

appear: Joints position insufficiently accurate and/or Negative (positive) adjustment is

required. In which case position the robot on the reference notches more accurately, as de

-

scribed.

6.

From the PTU4 command menu execute: Conf (F1) Arm (F1) Turn (F3)

7. Repeat the operation on all the robot axes.

INSTALLATION C3G Plus

2-18 08/0702

-

Loading...

Loading...