©2025 Copeland LP.

026-1803 R13 Supervisor I&O User Guide B - 3

Problems with Temp Sensor or

Pressure Transducer Displaying

Proper Value

16AI input dip switches are

set incorrectly.

The 16 dip switches on the 16AI board correspond

to each of the inputs:

Dip Switches Up = Temperature Sensor

Dip Switches Down = Pressure Transducer

Incorrect board and point

address.

Set proper board and point settings for both input

and output: Go to the Inputs tab in the application’s

Setup screen and check Board and Point.

Incorrect sensor type.

Verify that the sensor type in Site Supervisor is the

same as the sensor installed. (For example, “5V-

200PSI” is a 5-volt powered 200PSI pressure trans-

ducer, and “Temperature” is the standard Copeland

temperature sensor.

NOTE: The previous Eclipse and Standard sensors

are now 5V and 12V respectively.

For 16AI boards:

For Onboard I/O:

1. Log into the Supervisory Controller.

2. Click the

Site Map icon.

3. Under

Control Status, select System.

4. Click

Onboard IO along the bottom of the screen.

5. Click

Details.

6. Under

Onboard IO DETAILS, click Setup.

7. Check the desired sensor type value from the list

and click

Edit to make changes.

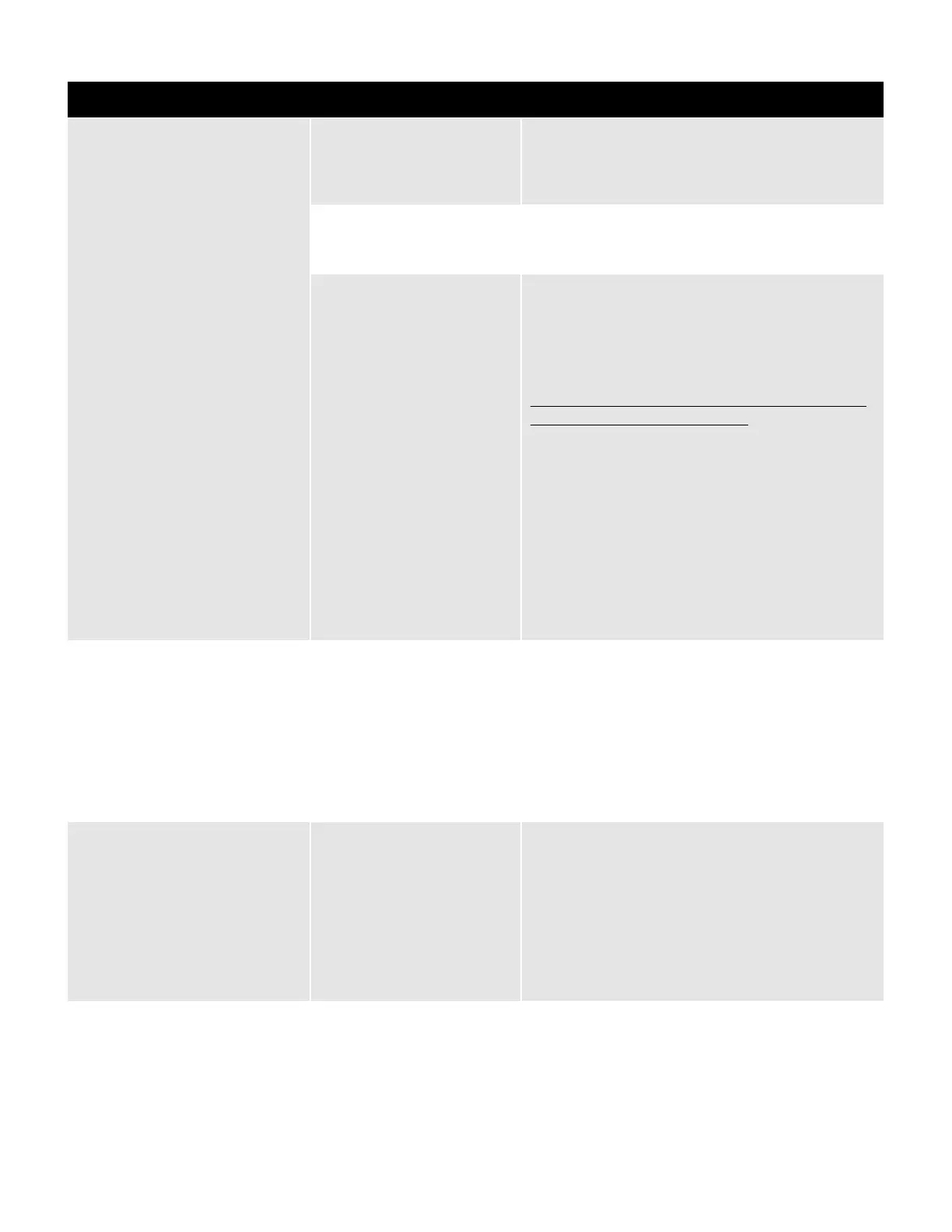

No Heat Will Come On

Incorrect board and points

assignment. Check the Heat

OAT lockout temps.

Make sure that your board and points are assigned

to the correct compressors and heat stages.

1. Log into the Supervisory Controller.

2. Click the

Site Map icon.

3. Under

Control Status, click HVAC.

4. Click

Details.

5. If

Heat Lockout En is enabled (set to ON), check

that Heat OAT LOCK is set to a valid setpoint

(temperature) for heat lock out.

No Cooling Will Come On

Incorrect board and points

assignment. Check the Cool

OAT lockout temps.

Make sure that your board and points are assigned

to the correct compressors and heat stages.

1. Log into the Supervisory Controller.

2. Click the

Site Map icon.

3. Under

Control Status, click HVAC.

4. Click

Details.

5. If

Cool Lockout En is enabled (set to ON), check

that Cool OAT LOCK is set to a valid setpoint

(temperature) for cool lock out.

SYMPTOM POSSIBLE PROBLEM SOLUTION

Loading...

Loading...