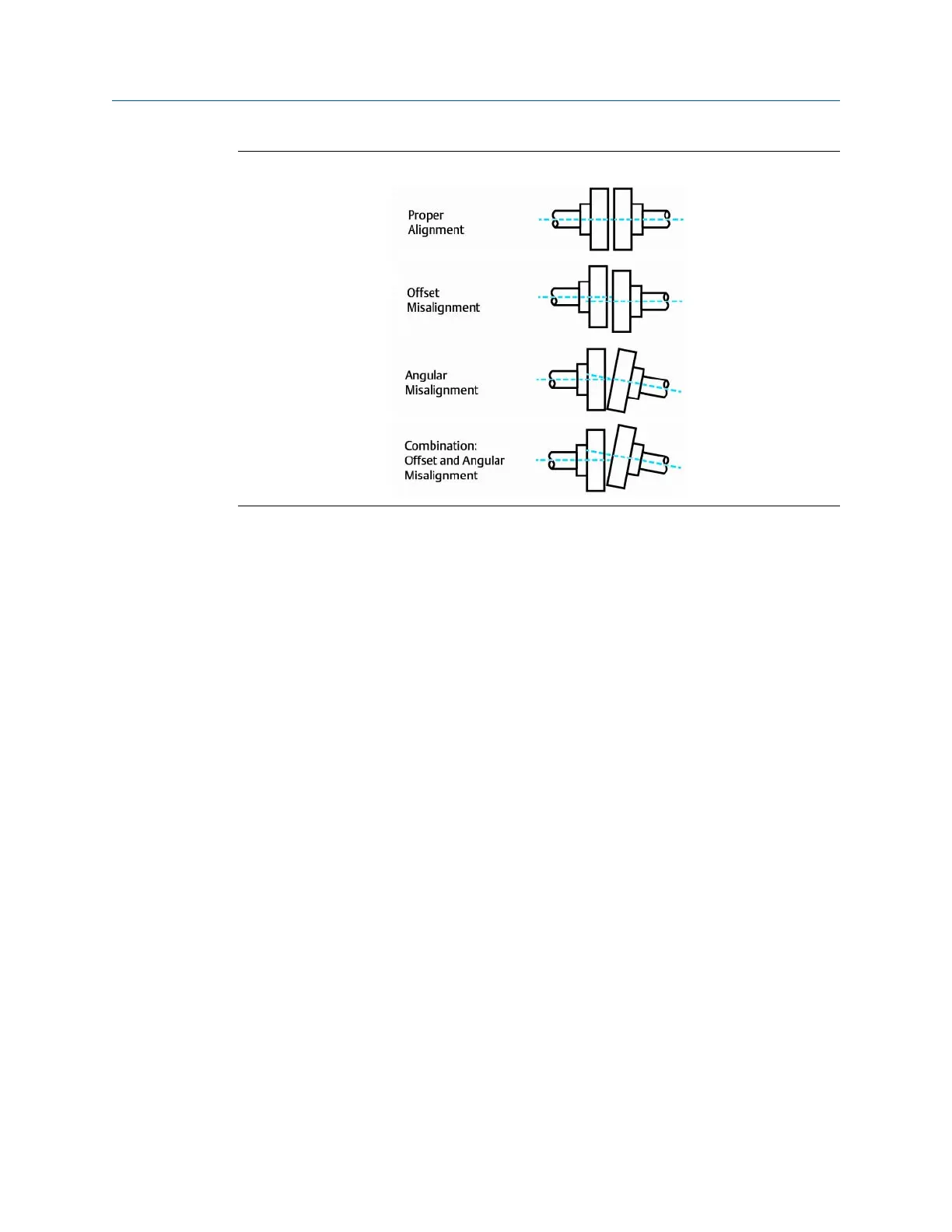

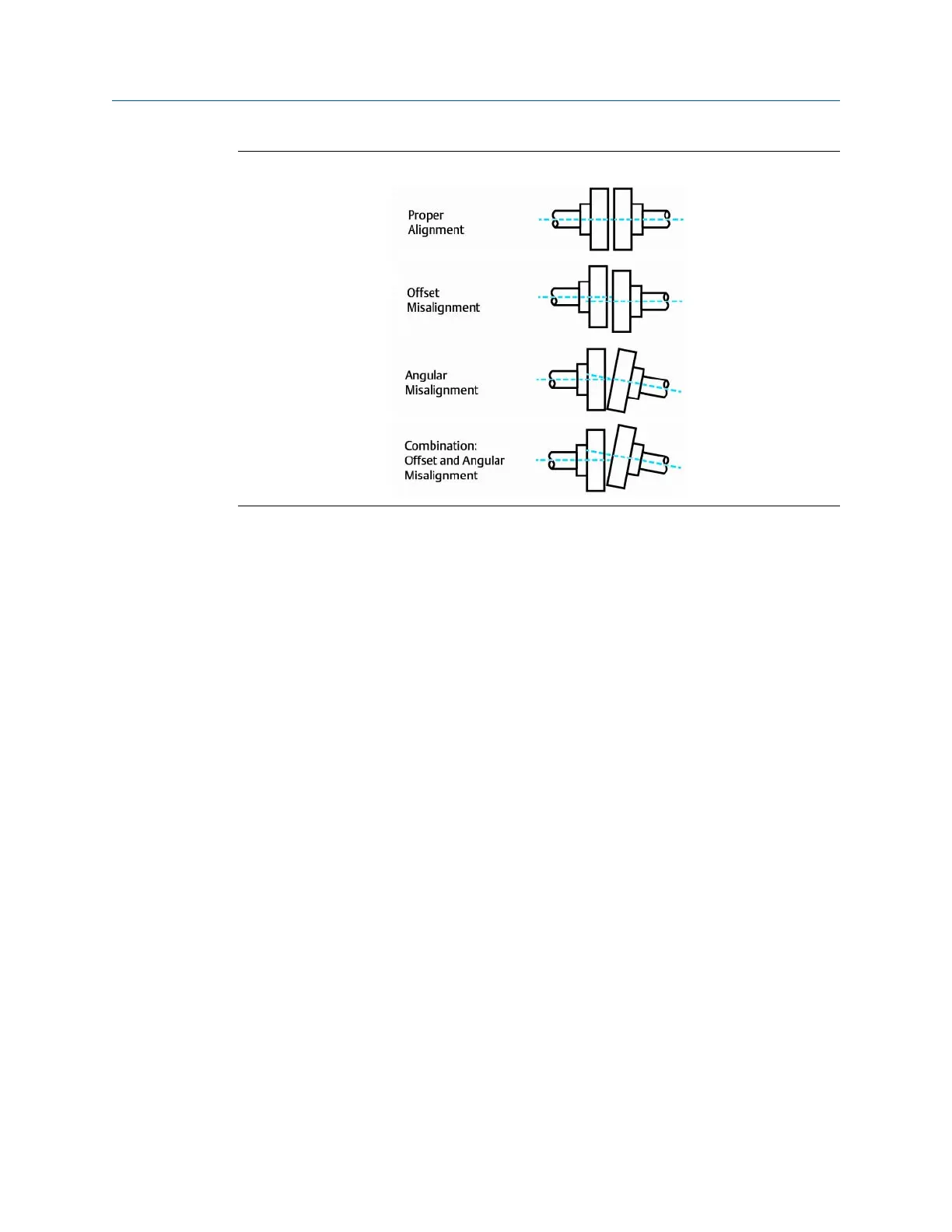

Alignment conditionsFigure 7-1:

Poor shaft alignment can cause problems such as bearing failure, shaft deflection fatigue,

seal leakage and failure, coupling failure, overheating, excessive energy consumption,

excessive machine vibrations, among others. Proper machine alignment results in less

downtime, increased bearing life, lower energy costs, extended coupling life, and lower

maintenance costs.

Properly aligning machine shafts involves at least the following steps:

1.

Preparation and setup—inspecting for soft foot, base integrity, pipe strain, and

knowing the acceptable tolerance levels. See Section 7.1.2.

2. Misalignment measurement—measuring the amount and direction of

misalignment.

3. Calculation of corrective moves.

4. Movement of the equipment within preset tolerances.

5. Storage and documentation of data for future alignment jobs.

7.1.2 Pre-job preparation and setup

1. Before starting any alignment job, review the history of alignments performed on

the machines.

Were there any special problems found during the previous alignment; if so, what

were they (soft foot, piping strain, coupling problems, etc.)? How well was the

machine aligned and who performed the alignment? Answering these questions

along with having a predefined job setup reduces the pre-job preparation time and

decreases the total time to perform the alignment.

2. Before proceeding with alignment measurements, ensure your machines are

mounted on the base, or foundation, with no soft foot condition present.

Advanced Laser Alignment

MHM-97432 Rev 7 163

Loading...

Loading...