GENERAL INFORMATION

- 12 -

For stubborn or damaged fasteners, the 6-point

provides superior holding because it contacts the

fastener across a wider area at all six edges. For

general use, the 12-point works well. It allows the

wrench to be removed and reinstalled without moving

the handle over such a wide are.

An open-end wrench is fast and works best in

areas with limited overhead access. It contacts the

fastener at only two points and is subject to slipping if

under heavy force, or if the tool or fastener is worn. A

box-end wrench is preferred in most instances,

especially when braking loose and applying the final

tightness to a fastener.

The combination wrench has a box-end on one

end and an open-end on one end and an open-end on

the other. This combination makes it a convenient tool.

Adjustable wrenches

An adjustable wrench or Crescent wrench (Figure

6) can fit nearly any nut or bolt head that has clear

access around its entire perimeter. An adjustable

wrench is best used as a backup wrench to keep a

large nut or bolt from turning while the other end is

being loosened or tightened with a box-end or socket

wrench.

Adjustable wrenches contact the fastener at only

two points, which makes them more subject to slipping

off the fastener. Because one jaw is adjustable and

may become loose, this shortcoming is aggravated.

Make certain the solid jaw is the one transmitting the

force.

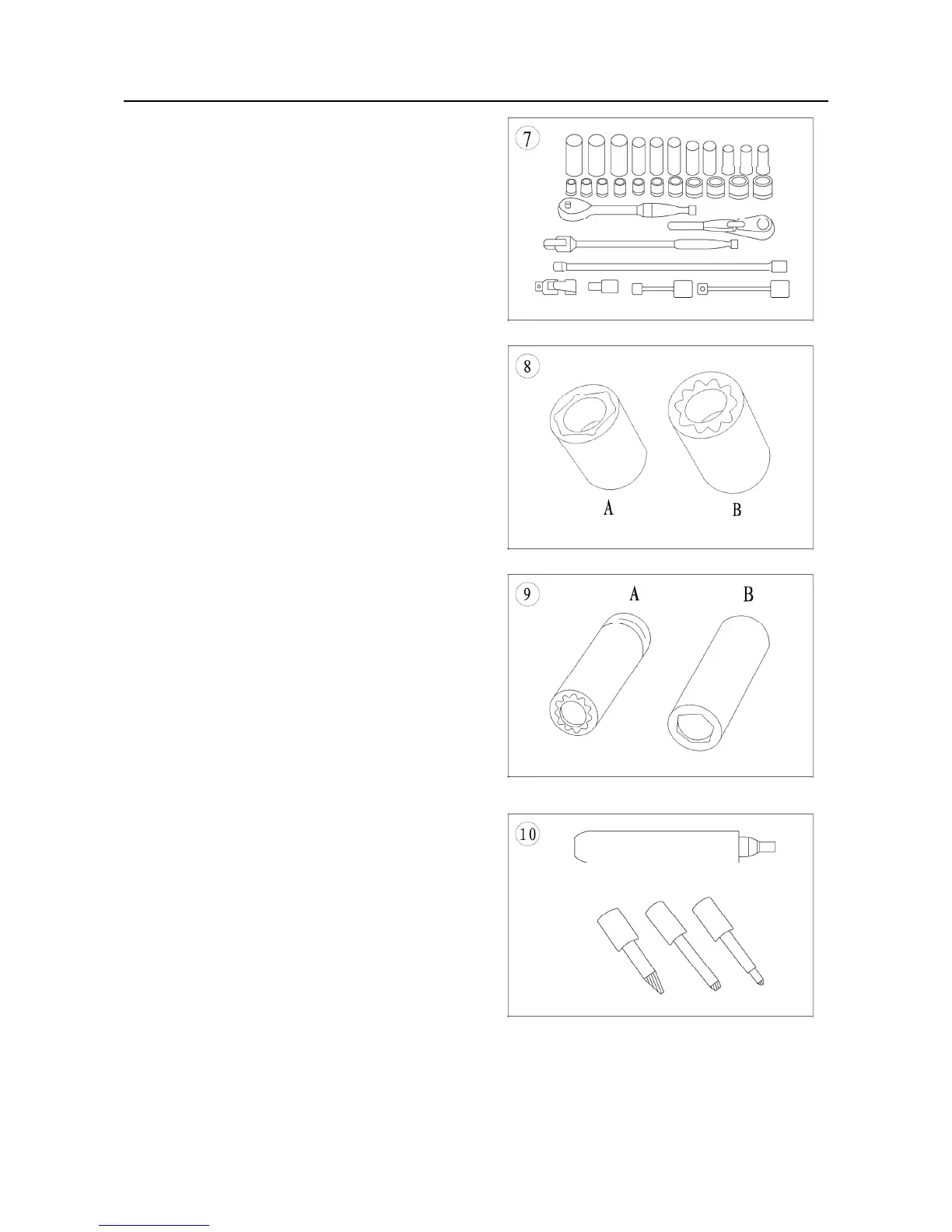

Socket Wrenches, Ratchets and

Handles

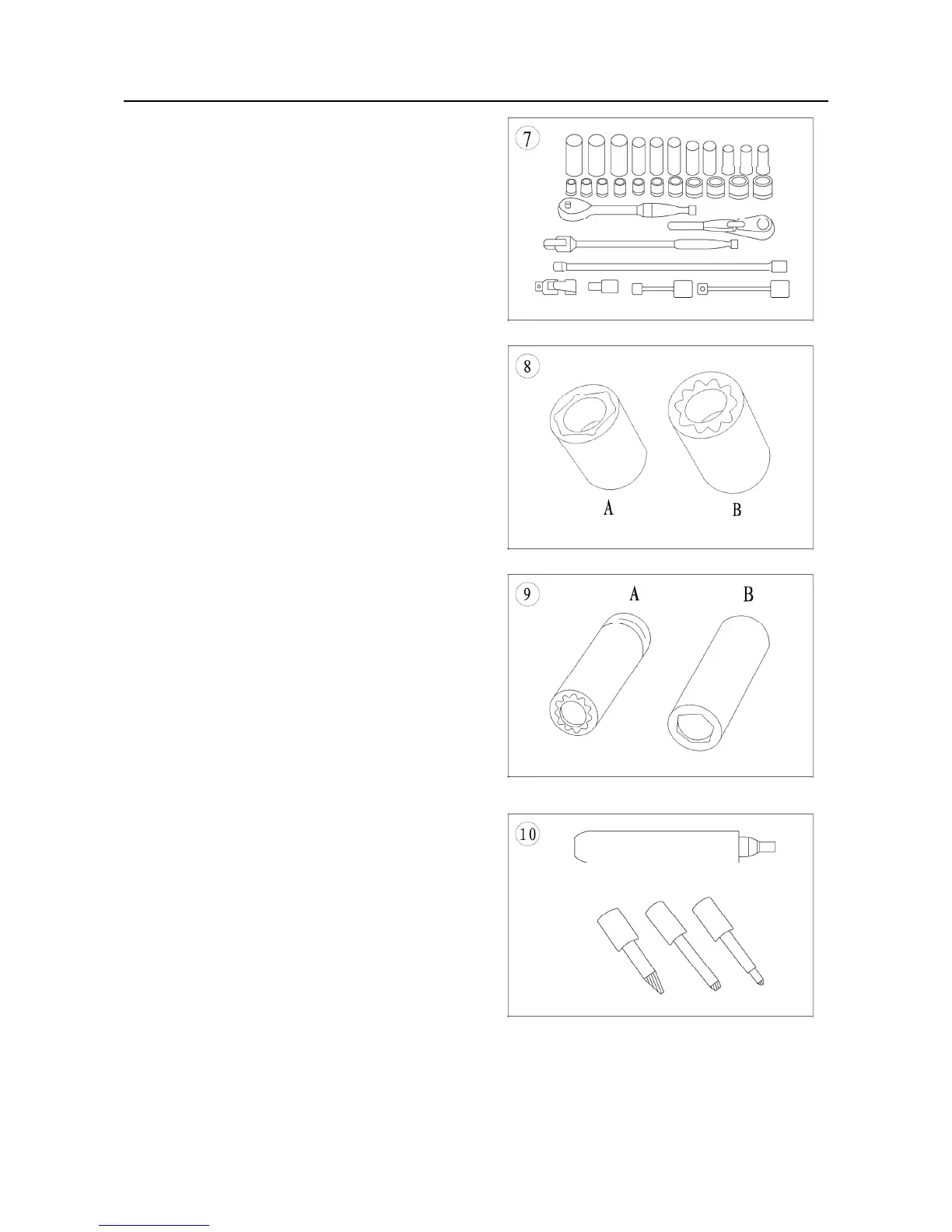

Sockets that attach to a ratchet handle (Figure 7)

are available with 6-point or 12-point openings (Figure

8) and different drive sizes. The drive size indicates

the size of the square hole that accepts the ratchet

handle. The number stamped on the socket is the size

of the work area and must the fastener head

As with wrenches. a 6-point provides superior-holding ability. While a 12-point socket needs to be

moved only half as for to reposition it on the fastener

Sockets are designated for either hand or impact use. Impact sockets are made of thicker material

Loading...

Loading...