GENERAL INFORMATION

- 27 -

While bearing are normally removed only when

damaged, there may be times when it is necessary to

remove a bearing that is in good condition. However,

improper bearing removal will damage the bearing and

possibly the shaft or case. Note the following when

removing bearings:

1. When using a puller to remove a bearing from a

shaft, take care that the shaft is not damaged.

Always place a piece of metal between the end

of the shaft and the puller screw. In addition,

place the puller arms next to the inner bearing

race. See Figure 40.

2. When using a hammer to remove a bearing from

a shaft. do not strike the hammer directly against

the shaft. Instead, use a brass or aluminum rod

between the hammer and shaft (Figure 41) and

make sure to support both bearing races with

wooden blocks as shown.

3. The ideal method of bearing removal is with a

hydraulic press. Note the following when using a

press:

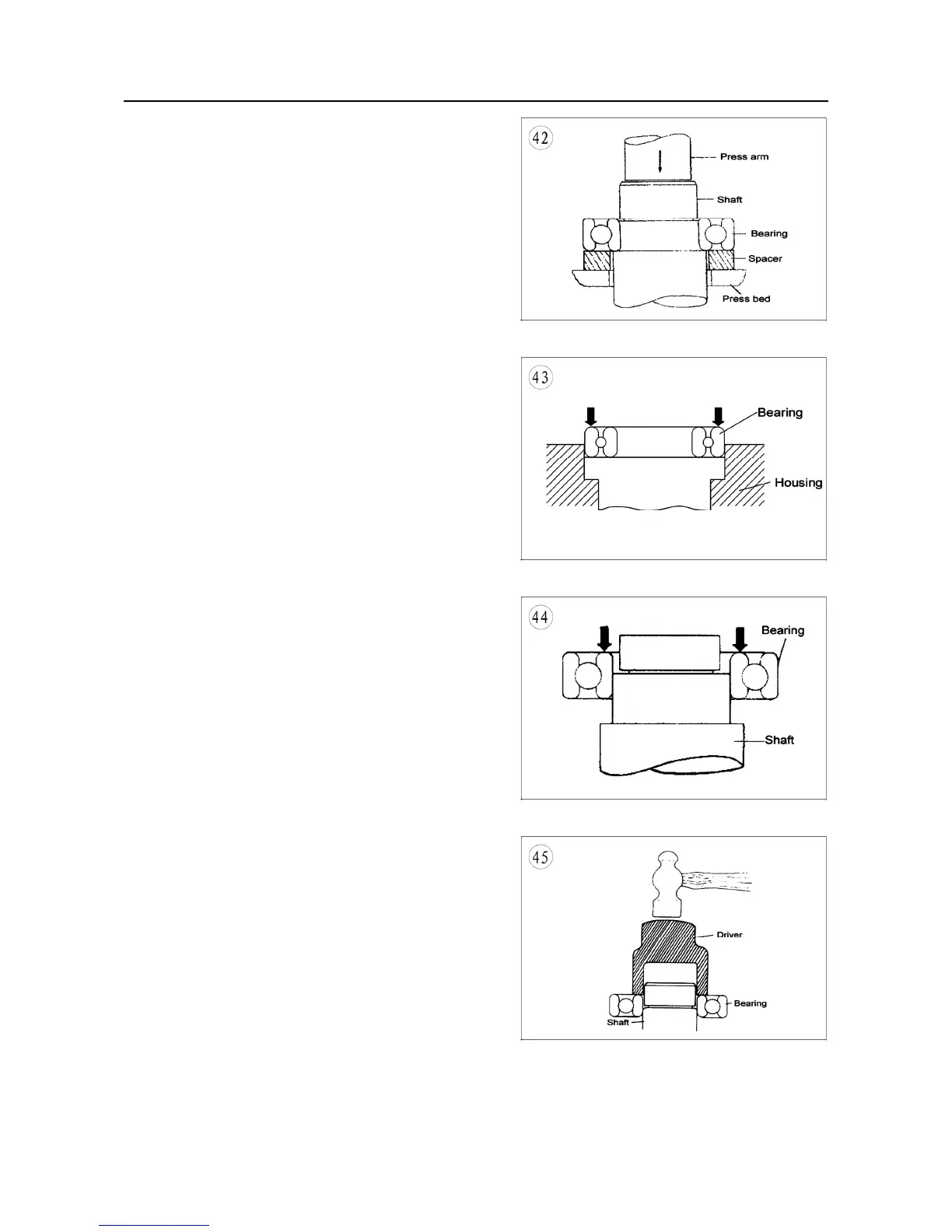

a. Always support the inner and outer bearing

races with a suitable size wooden or

aluminum spacer (Figure 42). If only the

outer race is supported, pressure applie

against the balls and/or the inner race will

damage them.

b. Always make sure the press arm (Figure

42) aligns with the center of the shaft. If the

arm is not centered, it may damage the

bearing and/or shaft.

c. The moment the shaft is free of the bearing.

It drops to the floor. Secure or hold the

shaft to prevent it from falling.

Installation

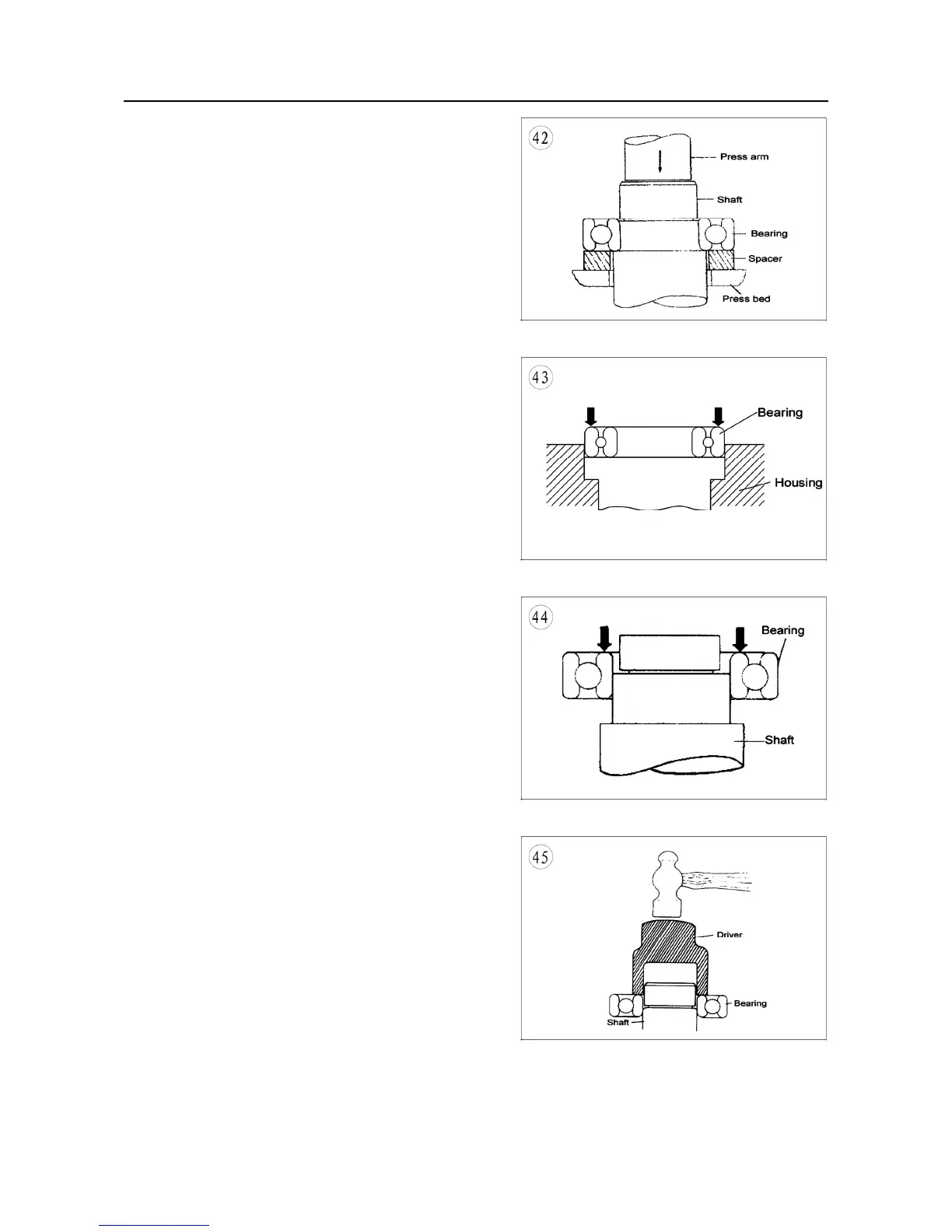

1. When installing a bearing in a housing, apply

pressure to the outer bearing race (Figure 43).

When installing a bearing on a shaft, apply

pressure to the inner bearing race (Figure 44).

2. When installing a bearing as described in Step 1,

some type of driver is required. Never strike the bearing directly with a hammer or it will damage

the bearing. When installing a bearing, use a piece of pipe or a driver with a diameter that

matches the bearing inner race. Figure 45 Shows the correct way to use a driver and hammer to

Loading...

Loading...