ENGINE MANAGEMENT SYSTEM

- 326 -

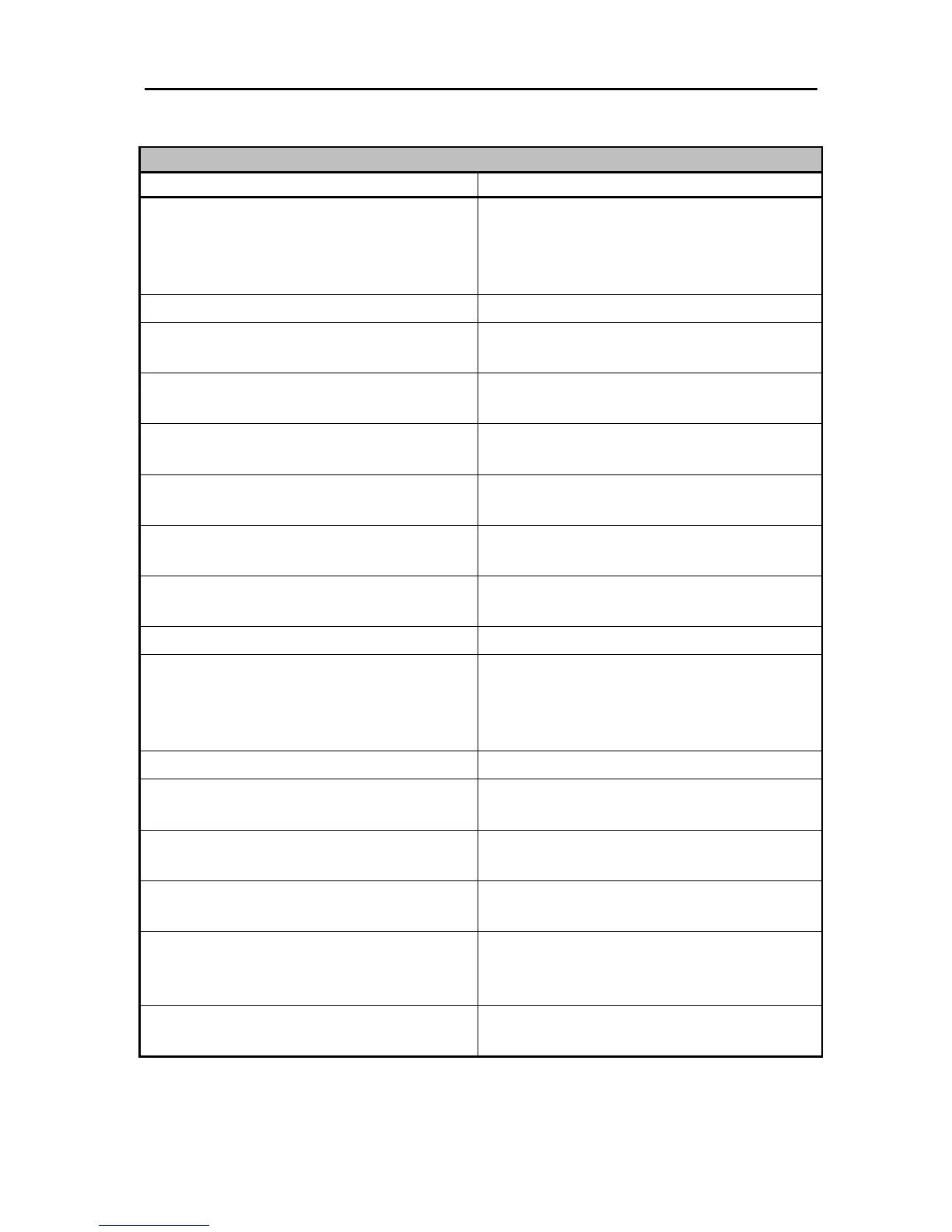

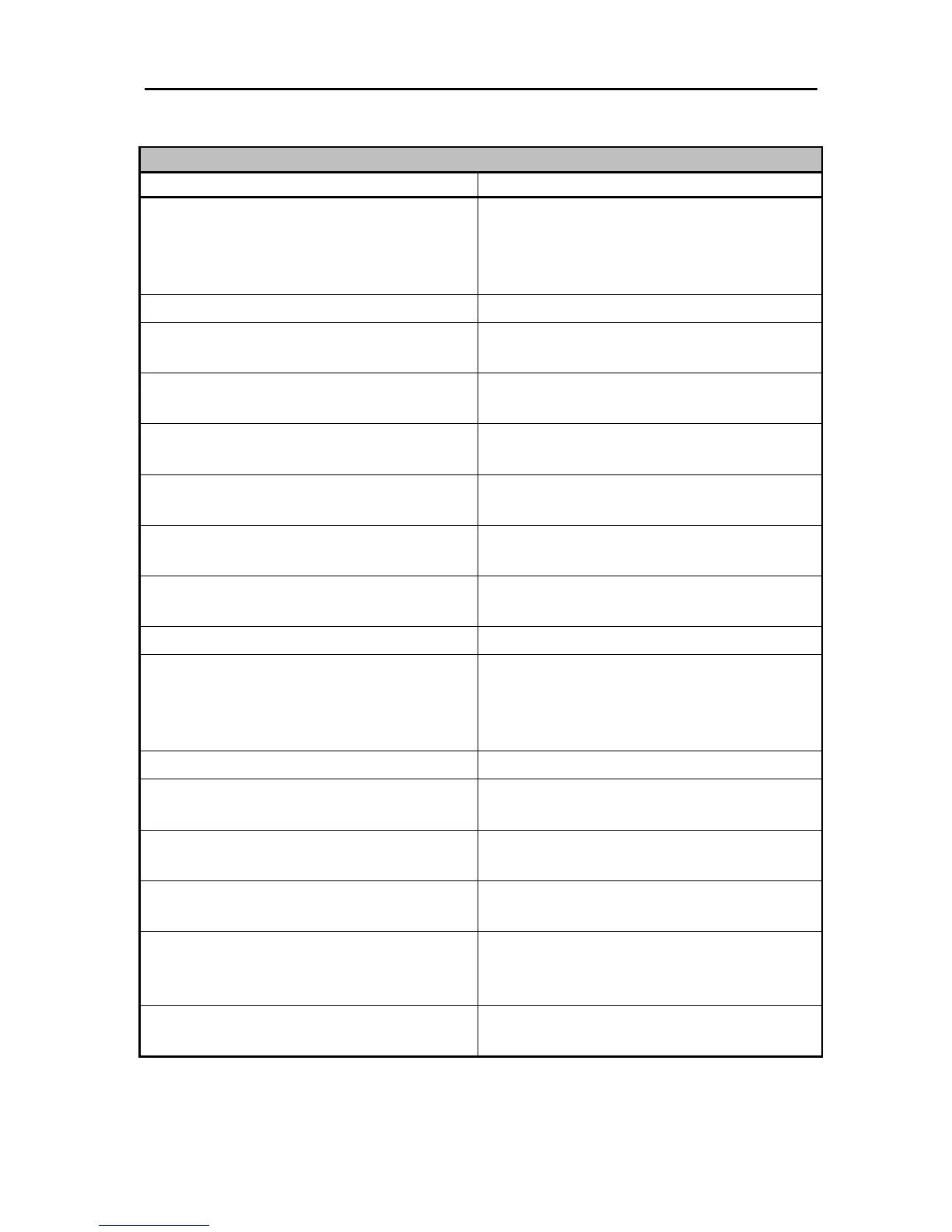

2.Handling - DOs & DONTs

3.5 FUEL INJECTOR HANDLING

ACTION REASON

DO NOT: Re-use injector seal rings if at all

possible. If no other choice exists, take

extra care in inspecting the seal rings for

damage.

Leakage.

DO NOT: Dip injector tips into lubricants. Can plug injector spray orifices.

DO NOT: Cycle injector repeatedly without

fuel pressure.

Damage to internal mechanical components.

DO NOT: Pulse (actuate) a suspected high

leak rate injector (leak >50 sccm air).

Can dislodge internal contamination if

present and preclude root cause analysis.

DO NOT: Allow water to enter fuel system

from air lines, etc. during leak checks.

Can damage injectors.

DO NOT: Contact or apply load to the

injector tip for installation.

Apply load to 45 deg angle on nylon over

mold see

DO NOT: Pound injectors into manifold

during assembly to engine.

Can damage injectors or seal rings.

DO NOT: Apply excessive side loads to

electrical connectors.

May cause loss of electrical continuity.

DO NOT: Use any dropped unit.

Internal damage may have occurred.

DONOT:Store injectors, rails, or

subassemblies including engines on which

the injectors have been installed in an

unprotected environment.

External contamination can damage the

injector electrically and/or mechanically.

DO NOT: Use the injector as a handle. Do not use the injector to lift assemblies

DO NOT: Rack, stage, or handle parts in a

manner that allows contact between parts.

Damage will occur.

DO NOT: Remove packing in a way that

allows contact between parts.

Damage could occur due ton contact

between parts.

DO NOT: Tap on fuel injectors to correct any

malfunction.

Can damage injector.

DO NOT: Replace the injector with other

part number not recommended for this

application

Will severely affect the performance of the

injector

DO: Take extra care when installing new

fuel seal ring over injector inlet flange.

Prevent tearing seal ring during installation.

Loading...

Loading...