ENGINE MANAGEMENT SYSTEM

- 341 -

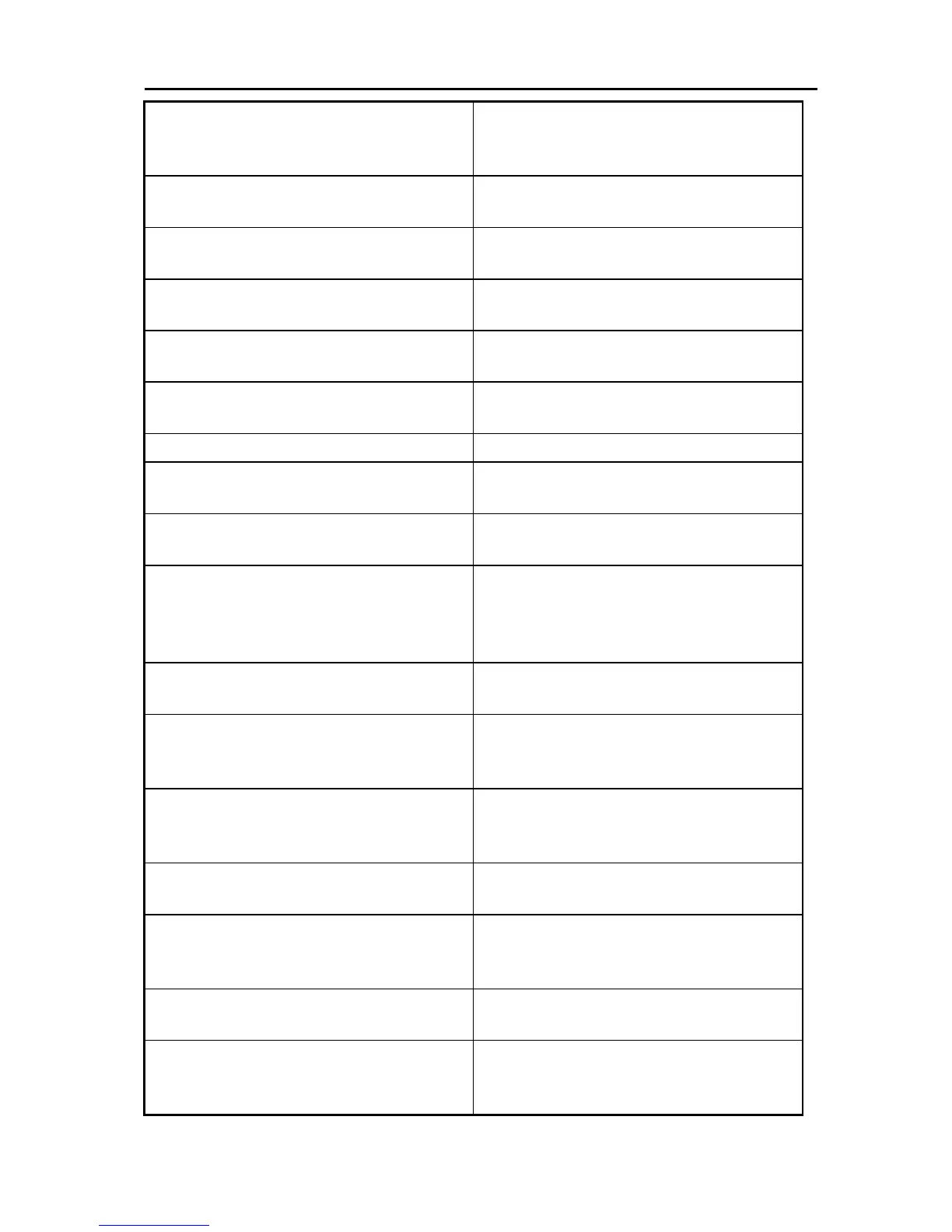

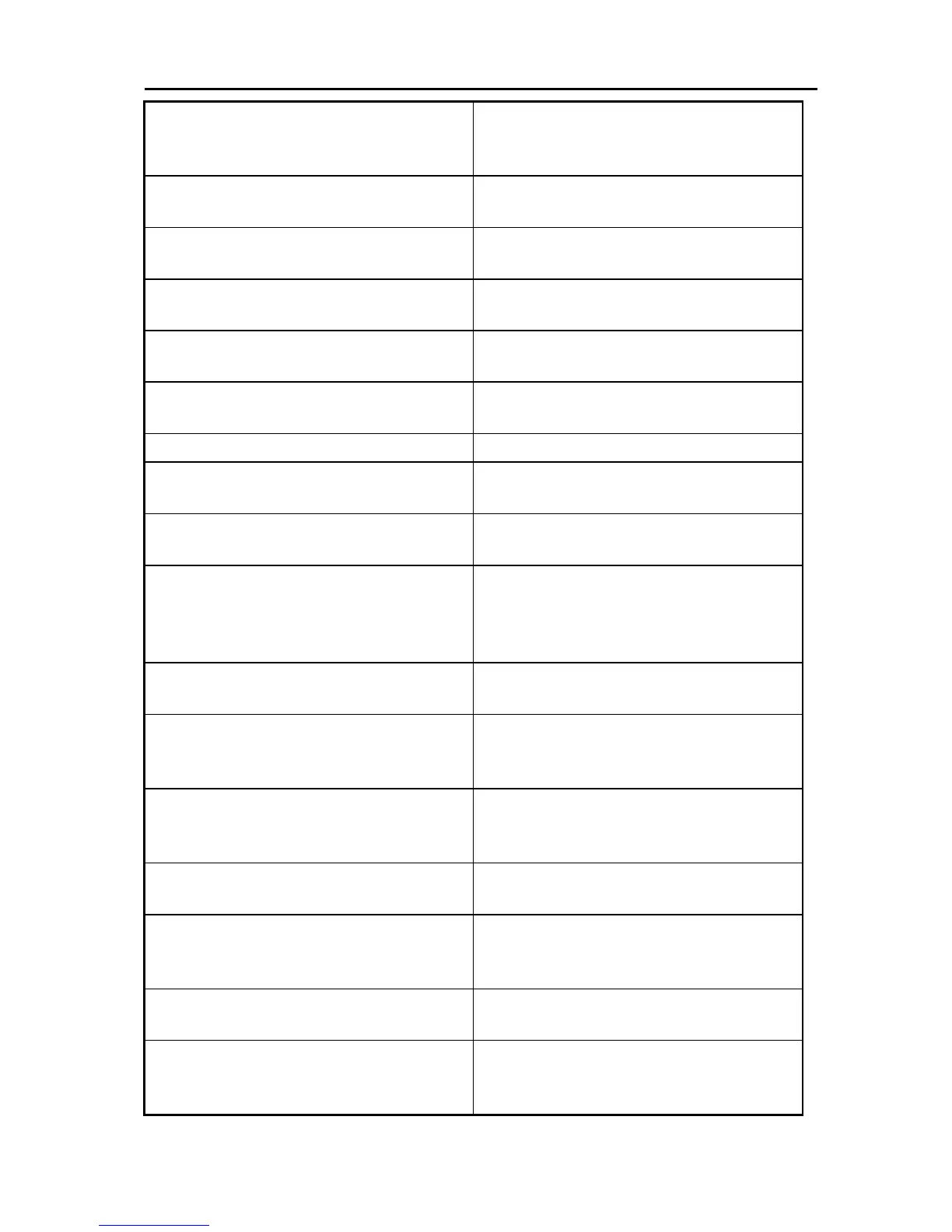

DO NOT: Use Fuel Module if the strainer

with excessive damage/ cut.

Contamination enters fuel pump thru

damaged strainer damages the Fuel

Pump

DO NOT: Use Fuel Pump for draining duel

in fuel tank.

Not intended function of fuel module.

DO NOT: Use module mounting bolts for

mounting other components.

Affects fuel module sealing.

DO NOT: Damage fuel pump harness

while servicing fuel module.

Damaged terminals will cause intermittent/

No contact for power supply.

DO NOT: Force hand pump towards fuel

module while draining fuel from tank.

To avoid any damages on fuel module.

DO : Ensure that there are no damages to

fuel pipes while servicing fuel module

Can cause fuel seepage/ leakage.

DO: Use genuine module gasket only. Spurious gaskets can cause leakages.

DO: Use designated hose clamps. To ensure no leakages/ seepages thru

hose joint.

DO: Clamp fuel module harness to vehicle

chassis

Clamp provides mechanical support for

wiring harness in vibrations.

DO: Use only standard gasoline for

operating vehicle/ module.

Fuel Module is intended to run in standard

gasoline. Adulterated fuel can cause fuel

module premature failures which are not

covered under warranty.

DO: Change the fuel filter at recommended

intervals.

Clogged fuel filter will cause restriction in

fuel flow and can cause flow reduction.

DO: Use fuel filters supplied/

recommended fuel filters only.

Spurious fuel filters causes damages to

injector, regulator and fuel pump

performance.

DO: Ensure that the hoses are routed

properly and there are no kinks / rubbing

with other components.

Improper routing, kinks and fouling of

hoses with other components causes hose

damage

DO: Ensure that always sufficient fuel till

the strainer height

Avoids Pump running in dry

DO: Replace two O-rings along with

replacement/ re-installation of pressure

regulator.

For proper functioning of regulator.

DO: Use care during connection of

harness to module coupler.

Avoid terminal damage.

DO: Return any dropped, damaged, or

suspect material with a tag that describes

the problem.

Ensure fast and correct diagnosis of root

cause.

Loading...

Loading...