NUTS, BOLTS, FASTENERS

Check thai all chassis nuts and bolts

are

tightened to

their correct torque values (page 1-9).

Check

that all safety clips, hose

clamps

and cable stays

are

in

place and properly secured.

WHEELS/TIRES

Tire pressure

should

be

checked

when the tires

ere

cold.

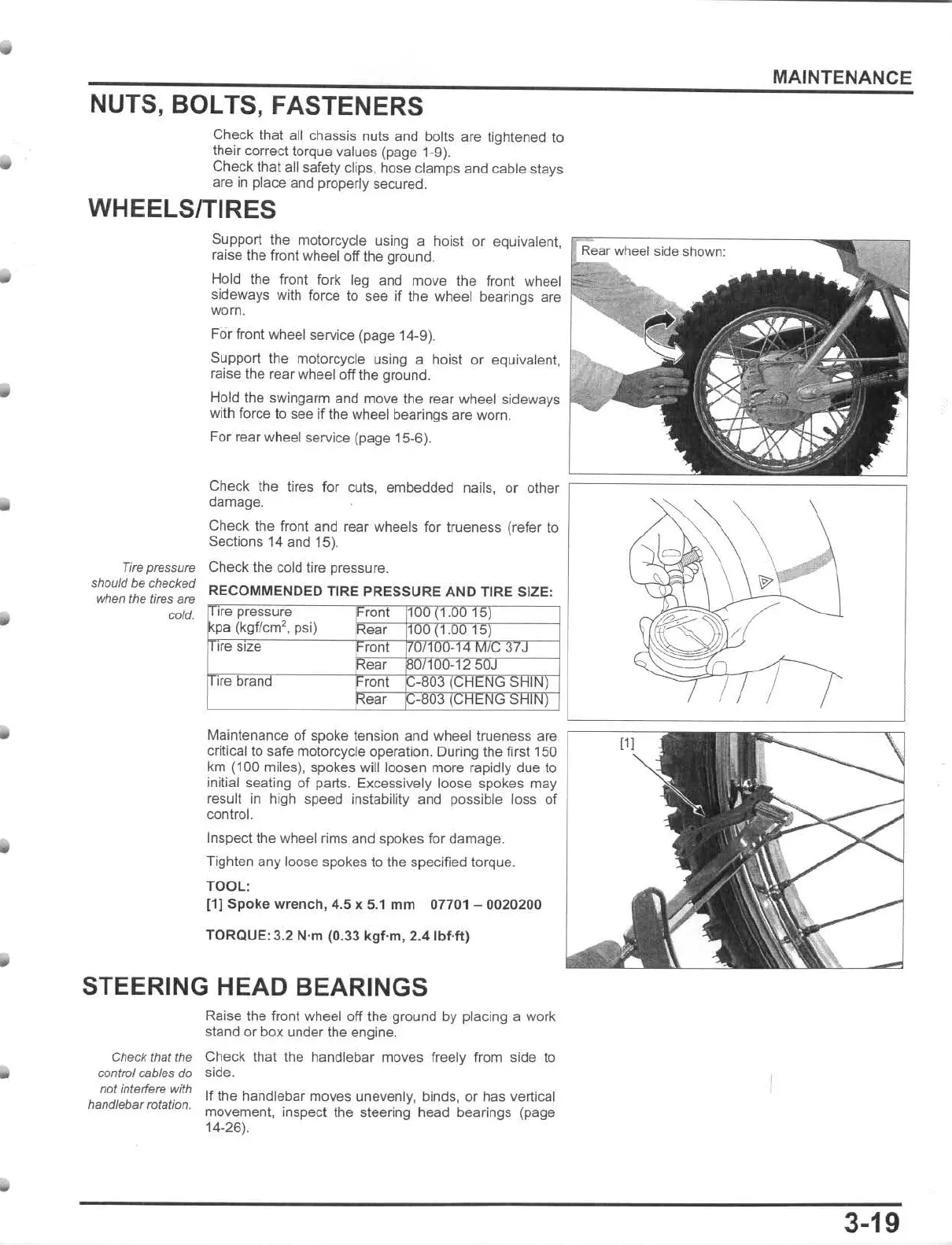

Support Ihe motorcycle using a hoist

or

equivalent,

raise the front wheel

off

the

ground.

Hold the front fork leg and move the front wheel

sideways with force to see

if

the wheel bearings are

worn.

For front wheel service (page 14-9).

Support

the motorcycle using a hoist

or

equivalent,

raise the rear wheel

off

the

ground.

Hold the swingarm and move the rear wheel sideways

...

_

....

with force to see

if

the wheel bearings are worn.

For rear wheel service (page 15-6).

MAINTENANCE

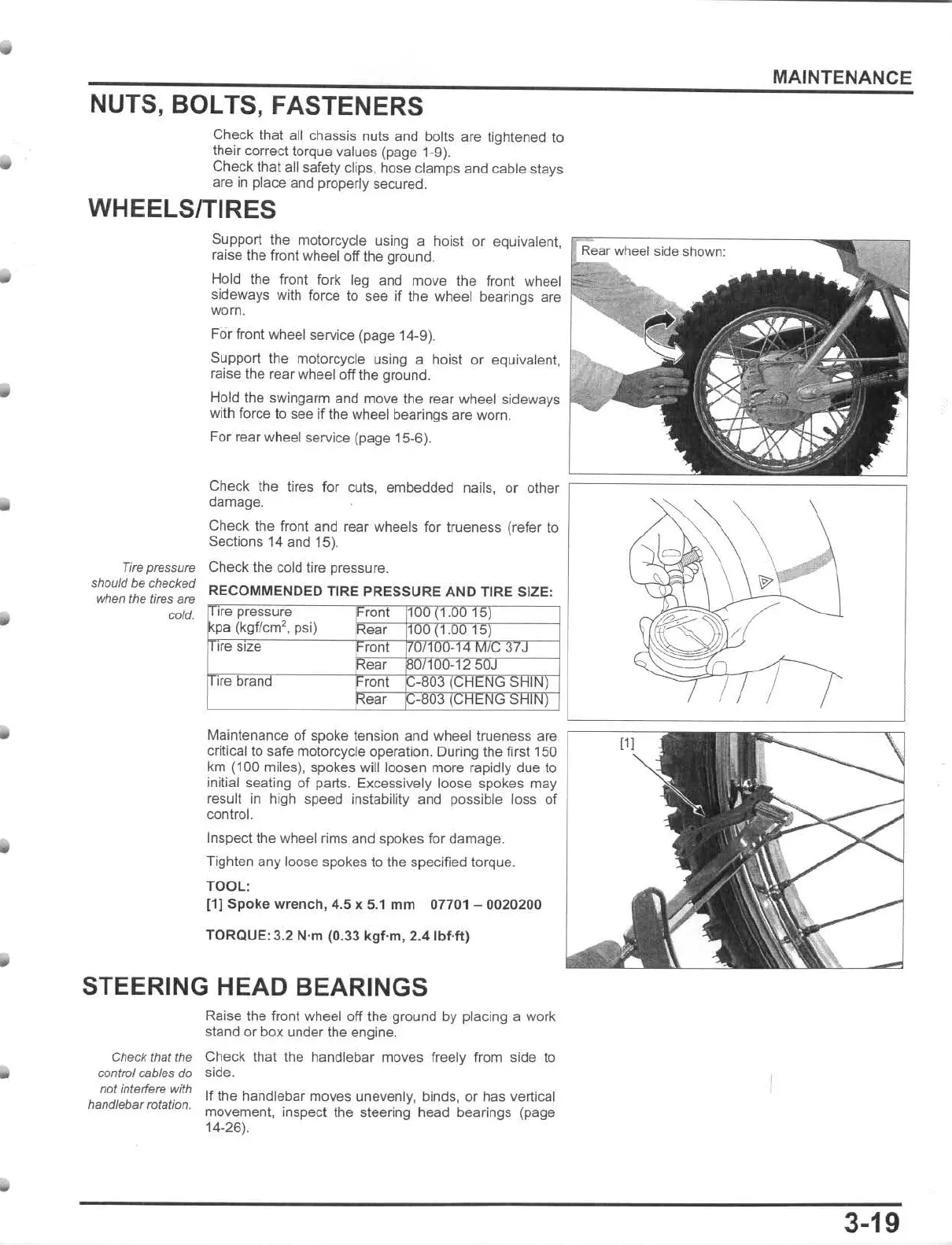

Maintenance

of

spoke tension and wheel trueness are

~

==~=

iiii

iii

Drir.ii::;':====~~

critical to safe motorcycle operation. During

the

first 150

km (100 miles), spokes

will loosen more rapidly due to

initial seating

of

parts. Excessively loose spokes may

result

in

high speed instability and possible loss of

control.

Inspect the wheel rims and spokes for

damage.

Tighten any loose spokes to the specified torque.

TOOL:

[1] Spoke wr

enc

h, 4.5 x 5.1 mrn 07701 - 0020200

TORQUE

: 3.2 N'm (0.33

kg

f'm, 2.4 Ib

Ht

)

STEERING HEAD BEARINGS

Check that the

control cables do

not interfere with

handlebar rotation.

Raise the front wheel

off

the

ground

by

placing a work

stand

or

box under the engine.

Check that the handlebar moves freely from side to

side.

If the handlebar moves unevenly, binds,

or

has vertical

movement, inspect the steering head bearings (page

14-26).

3-19

Loading...

Loading...