The

Ai

r screw is

factory pre-sel.

When not

necessary, do not

tum

or

disassemble

t

he

air

scrow

.

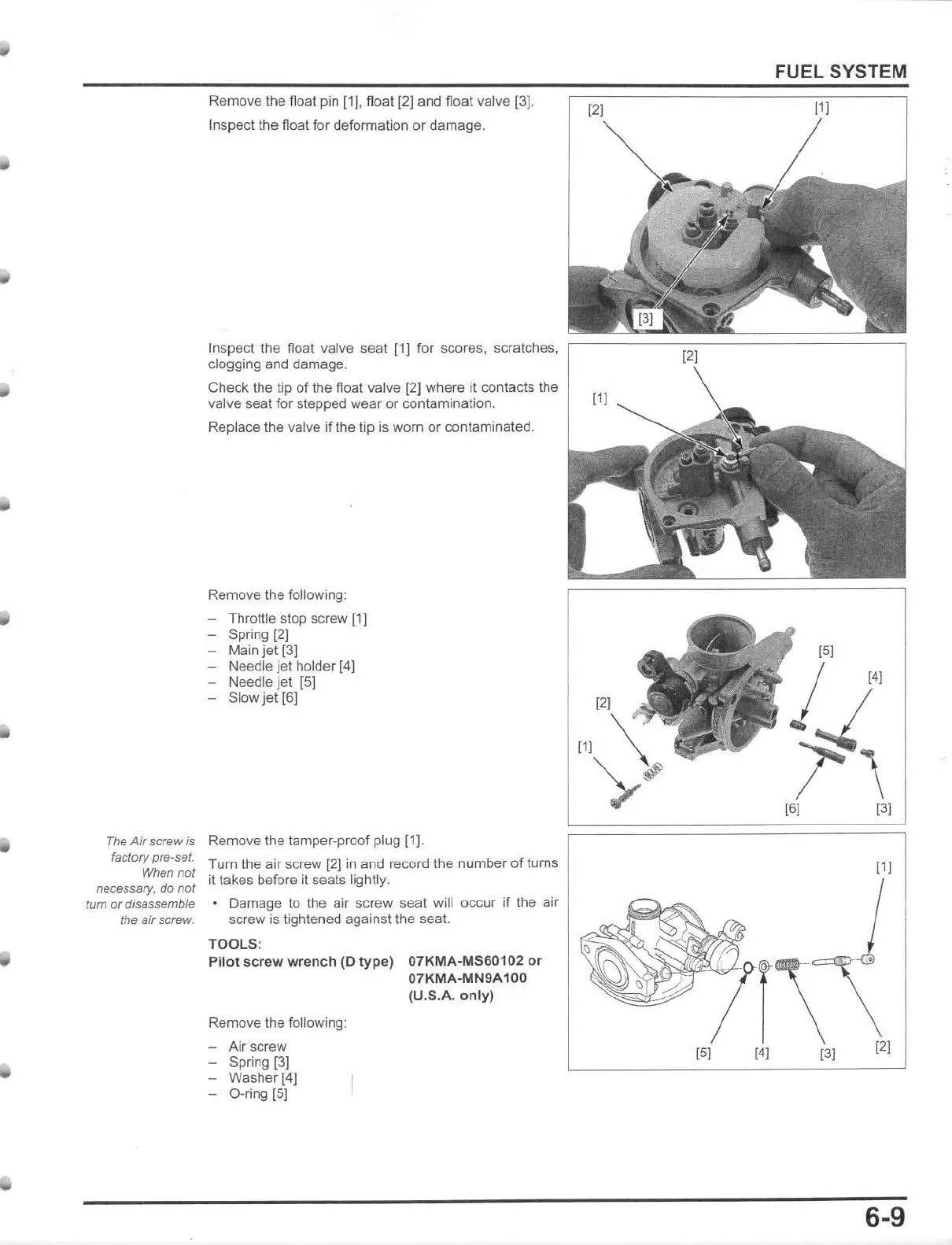

Remove

the float pin

[1

j, float [2] and float valve [3].

Insp

ect

the float for deformation

or

damage.

Inspect the float valve seal

[11

for scores, scratches,

clogging and damage.

Check

the tip

of

the float valve [2] where

it

contacts the

valve seat for stepped

wear

or

contamination.

Replace the valve

if

the

lip

is worn

or

contaminated.

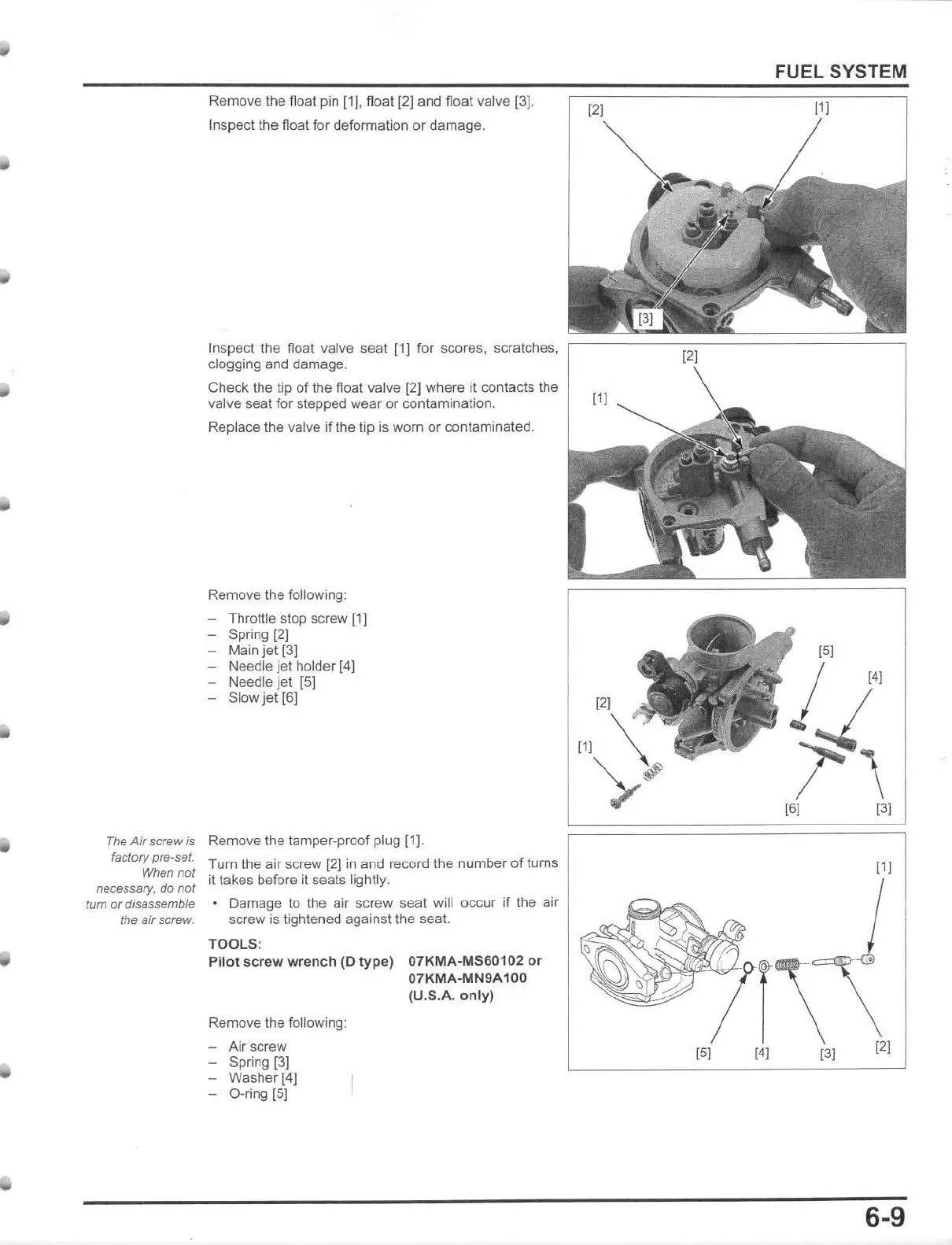

Remove

the following:

- Throllie slop screw

[1)

Spring

[21

Main

jet

(3)

Needle jet holder

[4

J

Needle

jet

[51

Slow

jet

[6)

Remove the

tamper

-proof plug [1).

Turn the air screw

{2J

in and record

the

number

of

turns

it

takes before il seals lightly.

• Damage

to

the air screw seal will occur jf the air

screw

is

lightened against

the

seat.

TOOLS

:

Pilot

screw

wrench

(0

type)

07KMA·MS60102

or

07KMA·MN9A100

(U.S.A.

only)

Remove the following:

-

Airscrew

- Spring [3]

-

Washer

[4]

- O·ring [5]

FUEL SYSTEM

[2[

[5[

/ [4[

A

[61

[31

[11

[51

[41 [31

1

21

6-9

Loading...

Loading...