GASLAB Q2 AFTER DELIVERY AND AT THE PLACE OF USE

Information for general use

Rev. M / 73023639

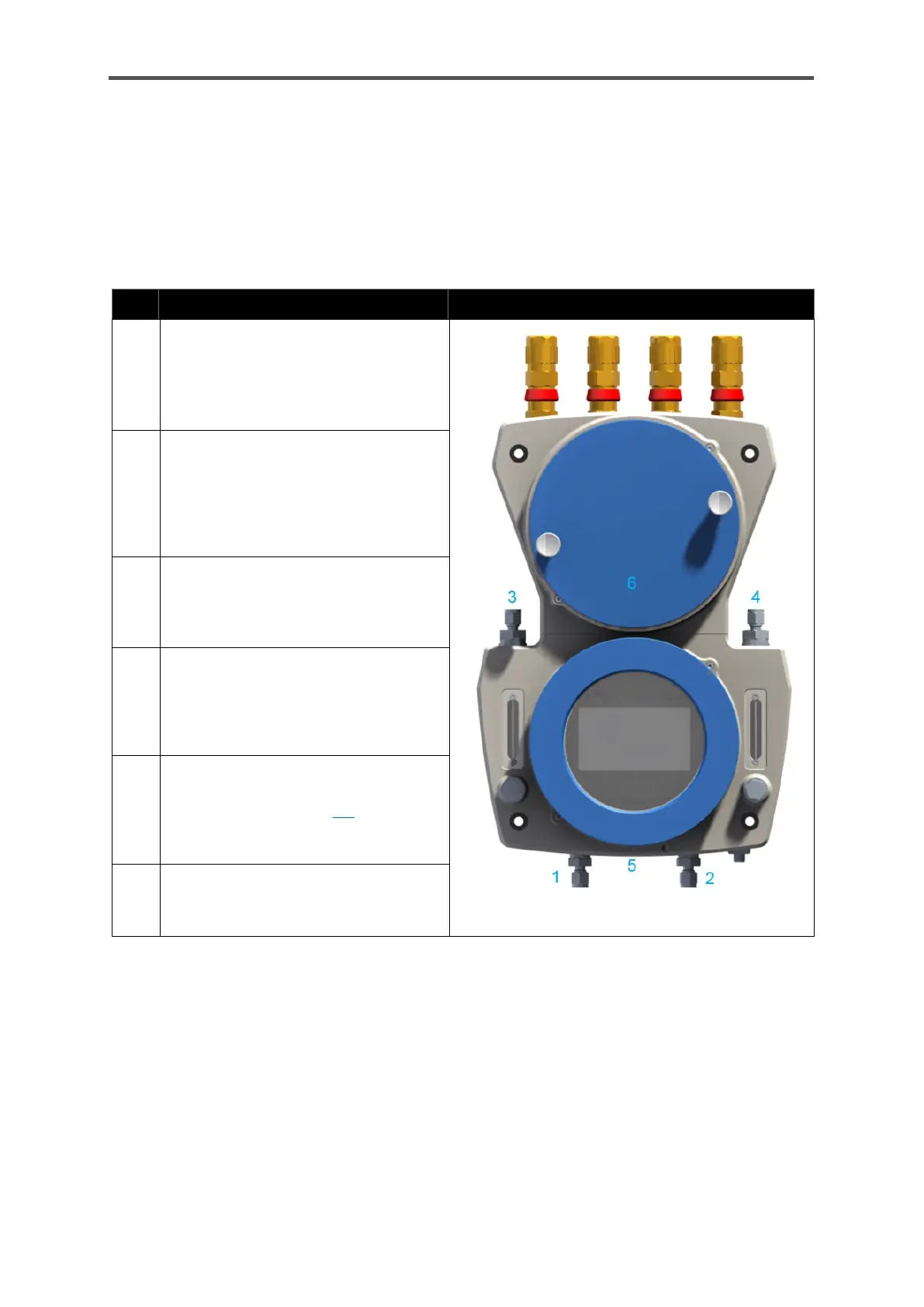

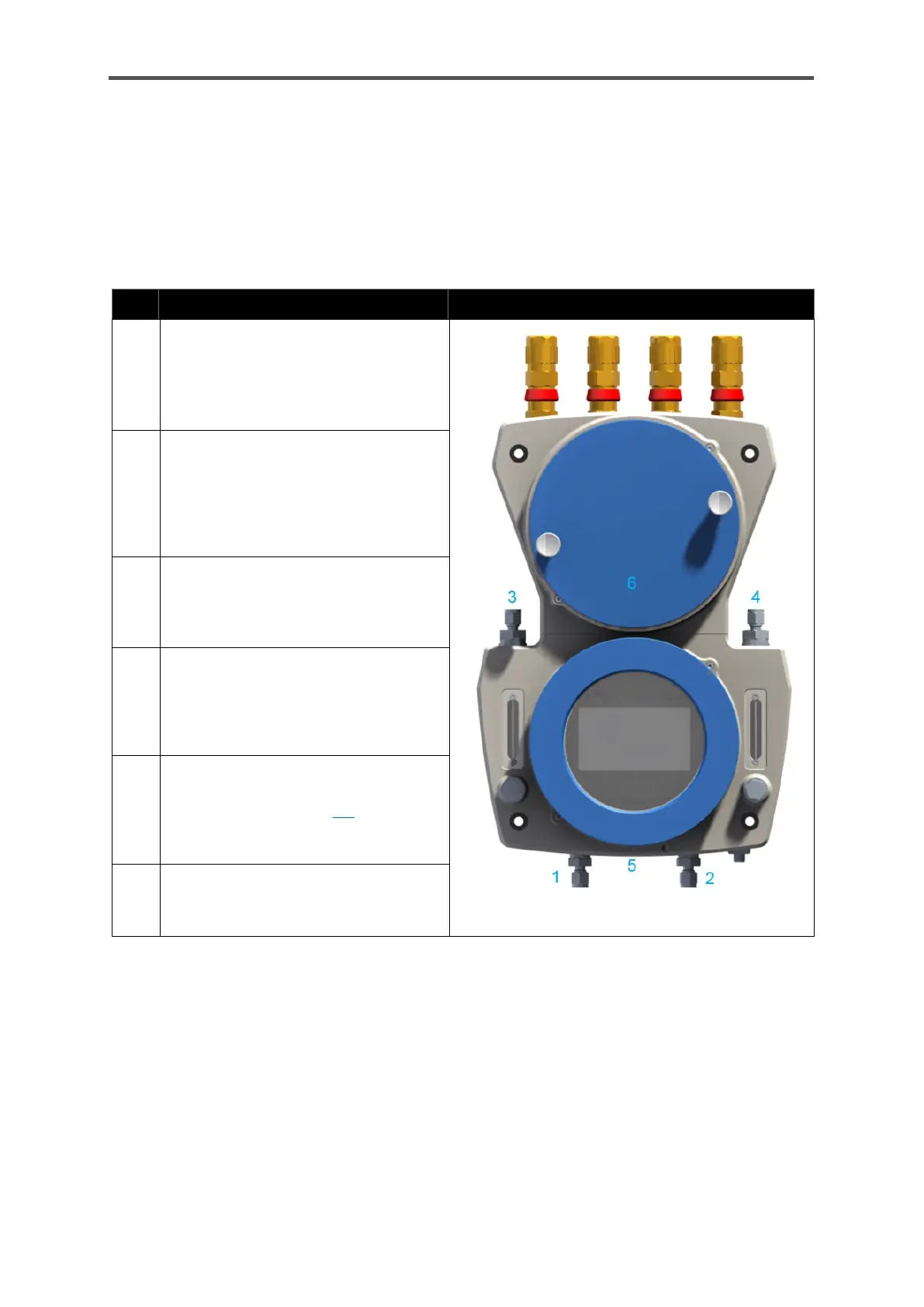

5.3.1. Fluid interfaces

GasLab Q2 has 2 gas inlets and two gas outlets, each of which is protected by a flame arrester. Two

breathing points are used to enable atmospheric pressure equalisation between the inside of the

device and the environment.

An overview of all gas inlets and breathing elements is shown in the following figure:

Process gas (PG) with integral particle

filter to act as a frit in the gland

Inlet pressure (gauge):

from 0.15MPa ≙ 21.76psi ≙ 1.5bar

to 0.3 MPa ≙ 43.51psi ≙ 3bar

Calibration gas cylinder (CAL)

Operational calibration gas (CH

4

+

CO

2

)

Inlet pressure (gauge):

from 0.15MPa ≙ 21.76psi ≙ 1.5bar

to 0.25MPa ≙ 36.26psi ≙ 2.5bar

Outlet from integrated bypass

Flow rate up to around

300 l/h ≙ 0.3 m

3

/h ≙ 10.59ft

3

/h

(if necessary)

Outlet from sensor path

Typical flow rate

1.059ft3/h ≙0.03m

3

/h ≙30l/h

Max. flow rate

2.118ft3/h ≙ 0.06m

3

/h ≙ 60l/h h

Main breather with

¼" NPT connection thread for pipelines

as described in section 2.6. If a pipe-

line is connected, it must be separate

from all other vent (waste) gas lines.

Auxiliary breathers (on the reverse)

Pipeline connection

not possible and not required

Figure 5.2: Definition of fluid connections

The gas connections are always equipped by the manufacturer in the standard version with 6 mm

Swagelok pipe screw unions. Alternatively, ¼ " is possible.

The process gas connection (bottom left) has an internal particle filter, which serves only as device

protection and is not a replacement for a primary filtration system. The right gas inlet is used to

connect the operating calibration gas or particle-free test gases.

The inlet pressure must not exceed the engraved maximum pressure at any inlet

Loading...

Loading...