MAINTENANCE, CLEANING AND REPAIR

Information for general use

Rev. M / 73023639

10.2. Completing a service calibration

An annual service calibration with 2 special gases is required to maintain measuring accuracy (this

may also be carried out more frequently if necessary). For non-fiscal use, you are permitted to carry

out this calibration yourself. The instructions for this are provided below. The required gases are

specified in section 11.4 Notes on device characteristics and operating conditions and in the

enSuite online help.

Have this work carried out by the manufacturer, or personnel contracted or trained

by it, in order to rule out the possibility of malfunctions caused by an unsuccessful

calibration and to avoid having to stock the special gases.

A gas inlet (generally the calibration gas inlet) must be connected to the service

calibration gases for this process.

Refer to all safety information when working on gas connections.

Une entrée de gaz (généralement l’entrée de gaz de calibrage) doit être raccordée aux gaz

de calibrage de service pour ce processus.

Respectez toutes les consignes de sécurité lorsque vous travaillez sur les raccords gaz!

Requirements: You must be logged in and there must be no current sensor errors. The components

of the two service calibration gases used with the selected gas inlets must be saved in the device

before the service calibration is carried out. These values can be most easily selected and entered

using enSuite at “Q2 >> Service calibration”. See the online help for support.

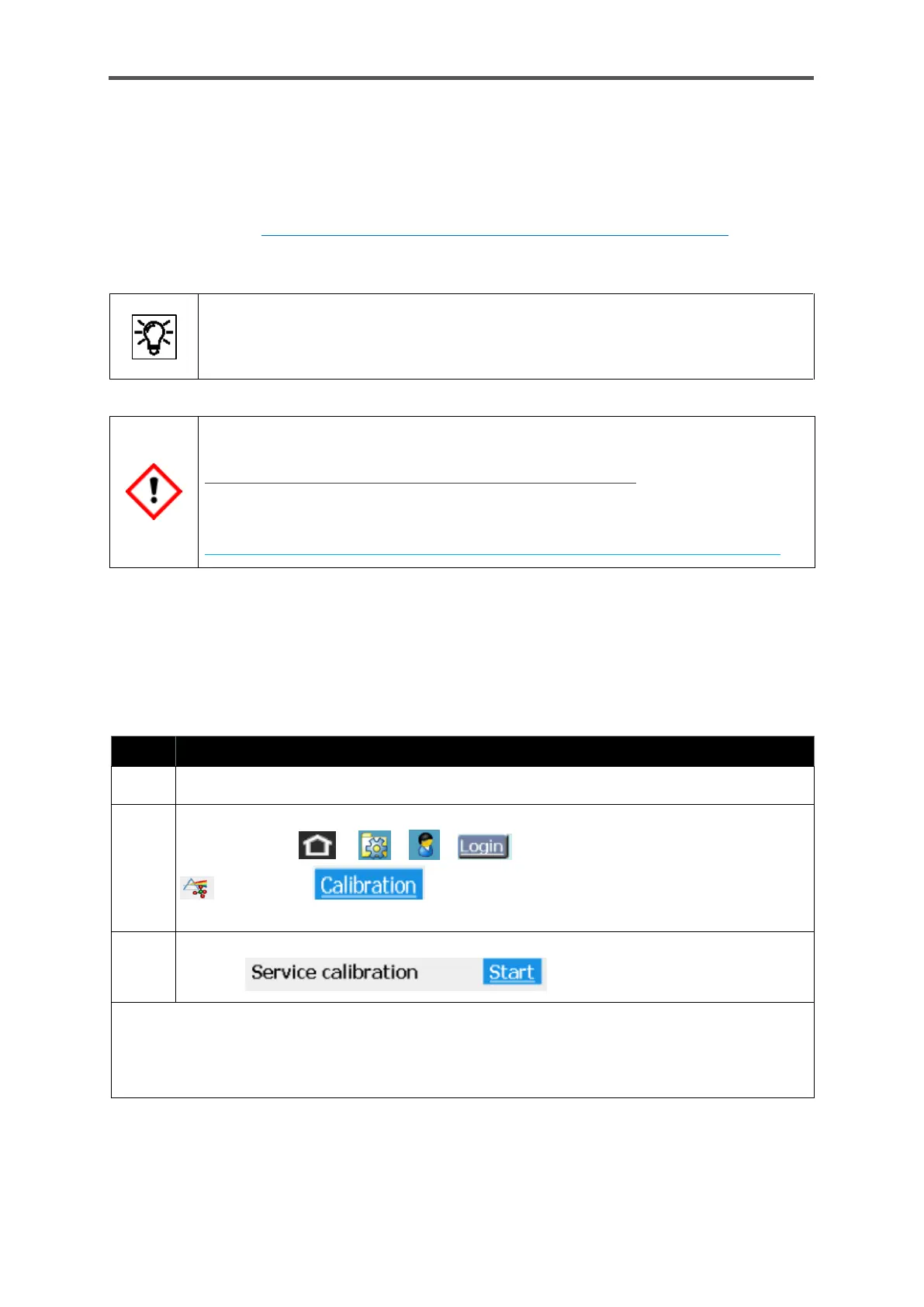

Action: Service calibration

Transfer the parameter set adjusted for the service calibration to the device.

Click on: Home -> -> -> and log in. Navigate to -> Q2 control

-> Calibration

Note: If an error occurs during the following steps, for example the pressure is inadequate, the

display will jump straight to point 10. Carry out steps 10 and 11.

Rectify the error and repeat the process from step 4.

Loading...

Loading...