REPAIR INSTRUCTIONS, PART 1

Page 173

Do not replace an entire rocker shaft assembly

(which includes the rocker arms, mounting

brackets, etc.) if only replacement of the shaft is

required. Reuse components which are not

damaged.

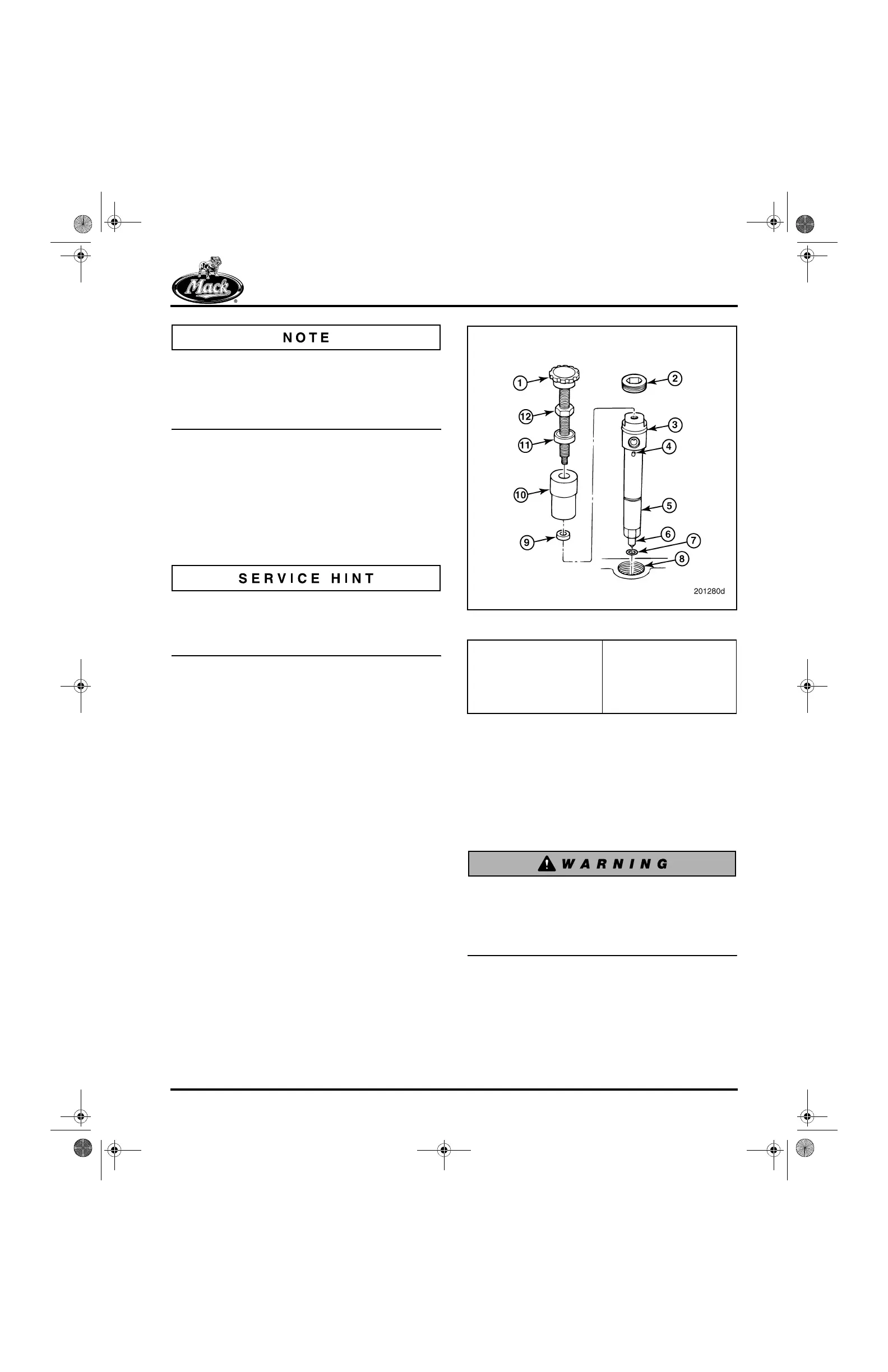

Nozzle Holder Removal

[222 KG]

SPECIAL TOOL REQUIRED

앫 Injection Nozzle Puller J 37093

After removing the nozzles, it is a good practice

to label or tag them for reinstallation into the

same cylinders. After removal, place nozzles on a

clean surface.

Refer to Figure 167.

1. Remove the nozzle holder retainer.

2. Assemble the injection nozzle puller J 37093

as follows:

a. Attach the nut, bearing, spacer and

rubber washer to the tool handle.

b. Install the handle in the threaded hole

of the nozzle holder until the rubber

washer is slightly compressed.

3. With the tool in position, turn the nut

clockwise to draw the nozzle holder from the

insert in the cylinder head.

4. Continue turning the nut until the nozzle

holder is free of the insert. Remove the

nozzle holder and puller tool as an

assembly.

5. Remove the nozzle holder gasket. The

gasket is manufactured from a special iron

material 0.060-inch (1.524 mm) thick.

6. Remove the remaining nozzle holders in the

same manner.

167

Figure 167 — Nozzle Holder Removal

Cylinder Head Assembly Removal

[213 EV]

Refer to Figure 168.

1. Remove the 20 mounting bolts from each

cylinder head.

Cylinder head assemblies are heavy. Lifting a

cylinder head requires the help of an

assistant or suitable lifting device. Attempting

to lift a cylinder head without assistance may

result in severe personal injury.

2. Using a suitable lifting device, remove the

heads from the cylinder block.

3. Remove the gaskets and six fire rings.

Discard the gaskets and fire rings.

1. Handle

2. Nozzle Holder Retainer

3. O-Rings

4. Alignment Pin

5. Nozzle Holder

6. Nozzle

7. Gasket

8. Nozzle Mounting Hole

9. Rubber Washer

10. Spacer

11. Bearing

12. Nut

5-111.bk Page 173 Monday, July 10, 2006 2:26 PM

Loading...

Loading...