REPAIR INSTRUCTIONS, PART 1

Page 273

LUBRICATION SYSTEM

BENCH PROCEDURES

Oil Cooler Assembly

Reconditioning

[215 DW]

See Cooling System Components Bench

Procedures in the REPAIR INSTRUCTIONS

section.

Oil Pump Reconditioning

[219 MU]

Because of differences in the gear set helixes, it

is important that the correct replacement parts

are used in making the repair.

앫 An improper drive gear on the oil pump will

prevent oil pump installation, assuming a

correct gear is on the auxiliary shaft.

앫 If an oil pump and an auxiliary shaft

assembly were replaced, two improper

gears could be installed, and engine failure

would result.

앫 In replacing any of these critical parts,

always refer to part number information in

the MACK Parts System to ensure the

correct component/part is being used.

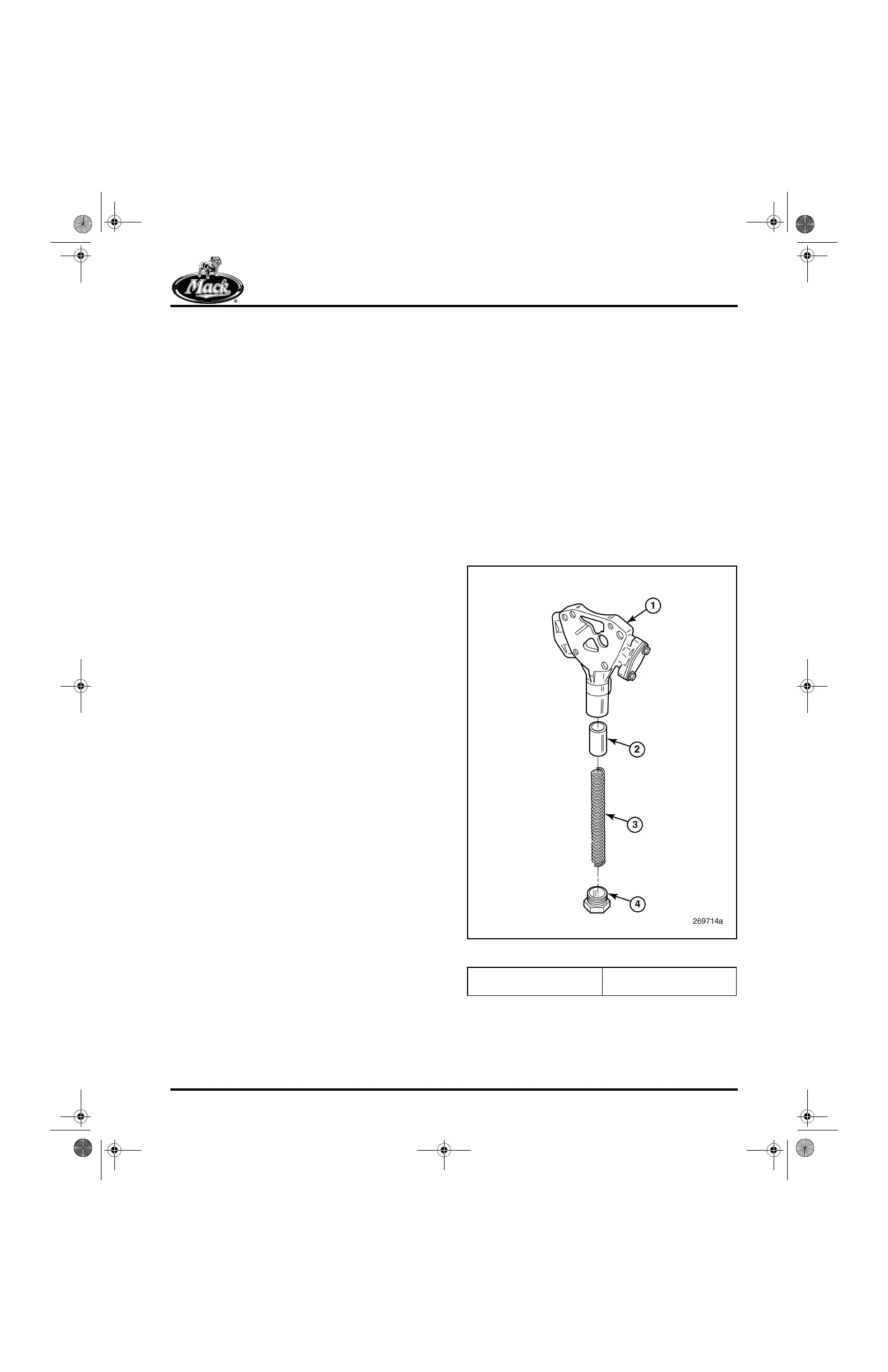

THREE OIL PUMP CONFIGURATIONS

Three different oil pump versions are possible in

an ASET™ engine dependent on date of

manufacture or if a remanufactured or new oil

pump has been previously installed. The main

difference in the three oil pump configurations is

in the oil pressure relief valve area. Other areas

of the pump, such as the gears and shafts,

remain basically the same. The three oil pump

configurations are as follows:

앫 Standard E-Tech™/ASET™

This is the original oil pump configuration

from production introduction of

E-Tech™/ASET™ through mid-2004.

Remanufactured oil pumps will be of this

configuration.

303

Figure 303 — Oil Pump Pressure Relief Valve

1. Oil Pump Housing Cover

2. Plunger

3. Relief Valve Spring

4. Relief Valve Cap

5-111.bk Page 273 Monday, July 10, 2006 2:26 PM

Loading...

Loading...