Page 378

REPAIR INSTRUCTIONS, PART 2

6. After installing the removal/installation tool

J 41682, remove the idler gear and hub.

Following camshaft installation, it is easier to

remove the camshaft removal/installation tool

J 41682 if the idler gear and hub have been

removed first. For this reason, the idler gear and

hub should be removed at this time.

7. Taking care not to damage the camshaft or

bushings, pull the camshaft out from the

front of the engine. Carefully guide the rear

of the shaft through the journals. If the shaft

does not come out freely, ensure that all

valve lifters are clear of the camshaft lobes

and journals.

8. Remove and inspect the valve lifters.

Valve lifters have established wear patterns and

should be reinstalled in the same locations. Label

each valve lifter upon removal and place it on a

clean work surface.

Cleaning and Inspection of Cylinder

Block

Salvaging a Damaged Valve Lifter Bore

Refer to “SALVAGING A DAMAGED VALVE

LIFTER BORE” on page 189 for complete valve

lifter bore repair criteria.

Salvaging a Damaged EUP Tappet Bore

Refer to “SALVAGING A DAMAGED EUP

TAPPET BORE” on page 188 for complete EUP

tappet bore repair criteria.

Cylinder Block Cleaning and Lifter Checks

While the camshaft is removed and lifter bores

are relatively accessible, it is a good practice to

clean all the lifter bores and then trial-fit all the

lifters into their respective bores and H-rings.

Clean and trial-fit lifters as follows:

1. Clean all lifter bores with a fresh supply of

suitable brake/parts cleaner. Ensure all

Loctite

®

residue and dried contamination

has been removed.

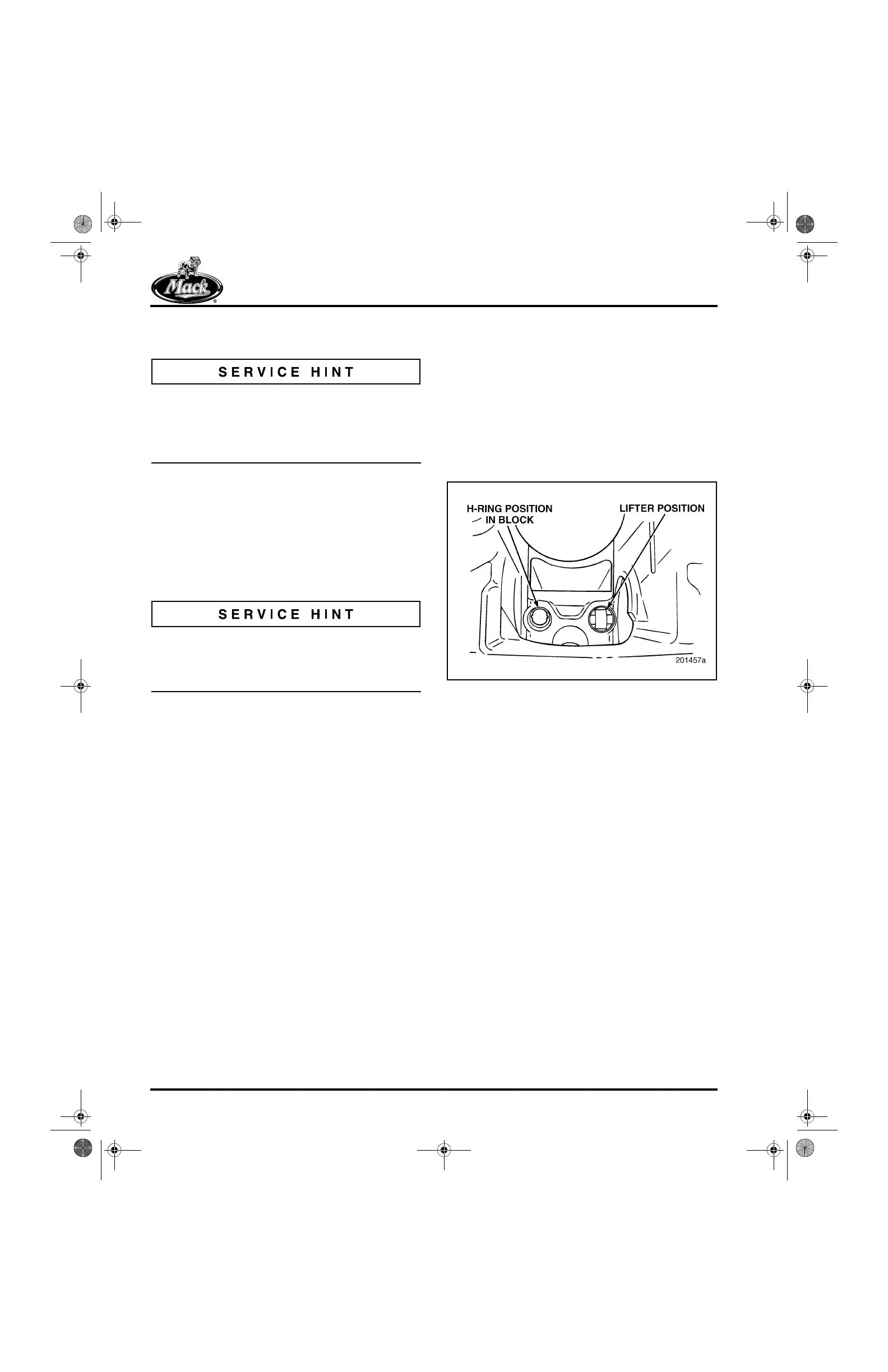

2. Trial-fit a lifter back into its original lifter bore

by aligning the lifter flats with the H-ring flats

as shown in Figure 453. Use only light finger

pressure when installing the lifters. Verify

that the lifter has complete freedom of

movement in the bore and H-ring in both the

upward and downward directions. When the

lifter is seated, it should be possible to rotate

it slightly from left to right. If the lifter is sticky

or tight, or if additional force was required to

install the lifter, proceed as follows:

453

Figure 453 — Installed Valve Lifter

a. If new lifters are being installed and the

fit is tight, try the lifter in another lifter

bore. A stack-up of component

tolerances can result in a lifter being

free in another bore. This is acceptable.

b. If the original lifters are being reused

and the fit is tight, trial-fit a new lifter(s)

in the bore. If the tightness persists, the

problem may be in the lifter bore or

H-ring. (Because of established wear

patterns, it is not recommended to

install a used lifter in any bore other

than the bore from which it was

removed.)

c. If the problem is confined to a particular

bore, determine if the lifter tightness is

due to the lifter bore or the H-ring by

trial-fitting another lifter. To correct the

problem condition, refer to the

procedure under “Salvaging a Valve

Lifter Bore” or “H-Ring Replacement” in

the CYLINDER BLOCK

RECONDITIONING section.

5-111.bk Page 378 Monday, July 10, 2006 2:26 PM

Loading...

Loading...